Singly-Reinforced Rectangular Sections

advertisement

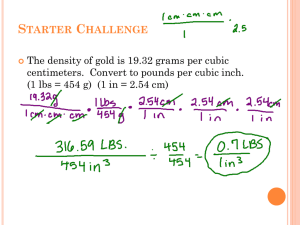

DESIGN FOR FLEXURE SINGLY REINFORCED RECTANGULAR SECTIONS The design of singly reinforced rectangular cross-sections for flexure may follow one of several methods. All of the methods described below are based on satisfying the same set of fundamental equations of equilibrium. Note that it is assumed that the cross-section is underreinforced, such that the tension reinforcement has yielded before failure. b .003 c h .85f 'c a=1c C = .85 f 'c a b NA d As sy T = As fy Force Equilibrium ("C=T"): a Asf y (1) .85 f 'c b Moment Equilibrium (assuming flexural strength provided = required strength): Mu M n a A s f y d 2 (2) Design for Cross-Sections of Known Dimensions In this case, b and d (or h) are assumed to be known prior to design. These dimensions may have been established by architectural considerations, or for other reasons (such as repeating beam dimensions across a span for formwork optimization). This is also typically the case for one-way slab systems, in which the width is assumed to be a 12inch wide strip and the depth is established by shear or deflection criteria. All three methods involve simultaneously satisfying both of the above equations. For the case of fixed dimensions, only the parameters a and As are unknown in these equations. Method 1: Trial and error (iterative) approach Method 2: Simultaneous algebraic solution Method 3: Solution by design aids 1 Design Problem The dimensions of the beam shown below are fixed as 10" x 20" for architectural reasons. The beam supports an indoor walkway on a 20-foot simply-supported span. The superimposed dead load is 1000 lb/ft and the superimposed live load is 1000 lb/ft. Select flexural reinforcement for the beam if the material properties to be used are f 'c = 4000 psi and fy = 60,000 psi. (Ignore the presence of any top bars used to facilitate stirrup placement.) LL = 1.00 k/ft DL = 1.00 k/ft h=20" 20 ft. b=10" Beam self-weight (assume concrete weighs 145 pcf): 2 1 ft k .145 10 in .20 in . 0.20 k / ft ft 3 12 in DLsw Total factored load: wu 1.2w D 1.6w L 1.21.00 0.20 k / ft 1.61.00 k / ft 3.04 k / ft Total factored moment (design for maximum moment along span): Mu w u2 8 3.04 k / ft 20 ft 2 8 152 ft. kips 1824 in . kips Assume 1.5 in. clear cover, 0.5 in. stirrup, and 1.0" diameter bars d = 17.5" 2 Method 1: Trial and Error (Iterative) Approach For this method, one of the variables a or As must be assumed, and then Equations 1 and 2 are solved iteratively until convergence. Typically, a is assumed and As is calculated by Equation 1. Then a is calculated by Equation 2 using the value for As calculated from Equation 1. The computed value of a is checked against the original assumption and the process is repeated until convergence. A typical starting assumption is that a = d/4 for beams a = d/6 for slabs. In most cases, these will yield slightly conservative values for a, and thus slightly conservative values for As. An alternative starting assumption is to assume the moment arm jd, where jd = (d - a/2). In this case, typical starting assumptions are jd = .875d for beams and jd = .925d for slabs. Using this process, As is first calculated from Equation 2, and then the assumption is checked using Equation 1. Note: When using this method, it is not necessarily required that the designer iterate until convergence is achieved. If the initial assumption is slightly conservative, then the result will be a slightly conservative design. The designer may check the capacity of the section based on the assumption, and if adequate and not overly conservative, complete the design at this stage. This philosophy is used in the solution below. Solution by Method 1 Assume jd: jd a d .875d .87517.5 in . 15.31 in . 2 Calculate As from Equation 2: Mu M n As a A s f y d 2 Mu a f y d 2 1824 in . kips 2.21 in .2 .90 60 ksi 15.31 in . At this point, iterate further or assume result is acceptable and analyze section: *We will not iterate, but if we had, we would get a = 3.83 in. and As = 2.17 in.2 Try 3 #8 bars (As = 2.37 in.2) 3 Analyze section: Actual d: d = 20" - 1.5" - 0.5" - 1/2(1.0") = 17.5" Check reinforcement limits (b from Text Table A-5): a a dt Asf y .85 f ' c b 2.37 in . 60 ksi 2 .854 ksi 10 in . 4.18 in . a 0.239 17.5 in . dt As 2.37 in . 10 in .17.5 in . bd min 3 f c' fy 4.18 in . 0.375 1 0.375 (.85) 0.319 (OK) TCL .0135 3 4000 psi .0032 60000 psi 200 .0033 (OK) fy Check section capacity (Equations 1 and 2): M n 4.18 in . a A s f y d .90 2.37 in .2 60 ksi 17.5 in . 2 2 1972 in . kips 1818 in . kips (OK) Check spacing and cover: Minimum spacing = 1" (ACI 7.6.1) Minimum cover = 1.5" (assume concrete is not exposed to weather) Assume minimum clear spacing and check cover. Cover = [b - 2(stirrup dia.) - 3(bar dia.) - 2(spacing)] / 2 sides = [10" - 2(0.5") - 3(1.0") - 2(1.0")] / 2 = 2" clear cover each side > 1.5 " minimum (OK) Note: several design aids are available for this step, such as Text Table A-6. 4 Method 2: Simultaneous Algebraic Solution For this method, Equations 1 and 2 are solved simultaneously to yield a closed form solution: Substitute Equation 1 into Equation 2: Mu A s f y A s f y d 1.7 f c' b (3) Rearrange Equation 3 into a quadratic form: Mu As 2f y 2 Asf yd fy2 0 1.7 f c' 1.7 f c' b As 2 b f y dA s M u Solve the quadratic equation for As (keeping only the root that makes physical sense): f yd As f y 2d 2 f y 2 M u 4 1.7 f ' b c fy2 .85 f c' b As f yd 1 M 2 u 1 .85 f ' bd 2 c fy2 .85 f c' b As .85 f ' c bd 1 f y Mu 2 bd 2 1 ' .85 f c (4) 5 or, in alternative form: .85 f ' c 1 f y Mu 2 bd 2 1 ' .85 f c (5) Either Equation 4 or Equation 5 may be used to solve directly for the required amount of reinforcement. Solution by Method 2 Solve for required As using Equation 4: Mu bd As 2 1824 in . kips .90 10 in .17.5 in .2 .662 ksi 662 psi 10 in .17.5 in . .854000 psi 1 60000 psi 2662 psi 2.17 in .2 1 .85 4000 psi Try 3 #8 bars (As = 2.37 in.2) Check reinforcement limits, analyze section, check cover & spacing as before… Method 3: Solution by Design Aids This method is identical to the method outlined above (Method 2), except design aids are used for the solution of the closed form equation. Repeating Equation 5 from above: .85 f ' c 1 f y Mu 2 bd 2 1 ' .85 f c (5) 6 Let us define the resistance coefficient Rn: Rn Mu bd 2 Several design aids have been published which tabulate Rn as a function of for various combinations of f 'c and fy. In using these design aids, Rn is typically stated in units of psi. An example of such a design aid is shown below: From: McCormac, Design of Reinforced Concrete Note: MacGregor Text has a similar set of design aid tables (Table A-3), except for one important difference. MacGregor defines the resistance coefficient as kn, which is identical to Rn. However, values are tabulated for kn, not kn. Therefore, one must essentially enter the tables after calculating Mu/bd2 (in units of psi) rather than Mu/bd2. The MacGregor design aid is shown on the next page: 7 From: MacGregor, Reinforced Concrete - Mechanics and Design 8 To simplify the process, a similar design aid has been published by several authors. This alternate design aid is a nondimensionalized design aid based on a modified form of Equation 5. Only one table is needed, regardless of the choice of f 'c and fy. Define the reinforcement index : fy f c' Now rewrite Equation 5 in terms of : .85 1 .85 1 M 2 u bd 2 f ' c 1 .85 M 2 u bd 2 f ' c 1 .85 1 2 . 85 .85 .85 2 1.7 2 2 .85 M u bd 2 f ' c 2 M 2 u bd 2 f ' c 1 .85 M u 2 bd 2 f ' c .85 M u bd 2 f ' c 1 0.59 (6) 9 A single table provides values for the term on the left side of the equation as a function of the reinforcement index w. This table is found in several publications, including PCA's Notes of 318-99, and is shown below: From: PCA, Notes on ACI 318-99 10 Solution by Method 3 Solve for required using design aids for Equation 5: Rn Mu bd 2 Mu bd 2 1824 in . kips .90 10 in .17.5 in .2 .662 ksi 662 psi or k n 1824 in . kips 10 in .17.5 in .2 .596 ksi 596 psi Entering table in MacGregor text (Table A-3) with kn = 596 psi, f 'c = 4 ksi, fy = 60 ksi, and interpolating linearly: required .0124 requiredbd A s, required .0124 10 in .17.5 in . 2.17 in .2 Try 3 #8 bars (As = 2.37 in.2) Check reinforcement limits, analyze section, check cover & spacing as before… Alternatively, using the design aid based on Equation 6: Mu bd 2 f c' 1824 in . kips .90 10 in .17.5 in .2 4 ksi .1654 Entering PCA Notes table with value of 0.1654, and interpolating linearly: required .1858 required required A s, required f c' fy required bd .1858 4 ksi .0124 60 ksi .0124 10 in .17.5 in . 2.17 in .2 Try 3 #8 bars (As = 2.37 in.2) Check reinforcement limits, analyze section, check cover & spacing as before… 11 Design for Cross-Sections of Unknown Dimensions In this case, b and d (or h) are not known prior to design. Therefore, we have three parameters that the designer must choose - b, h, and As (assuming f 'c and fy are established). These three parameters must only satisfy two equilibrium equations, so there are mathematically an infinite number of possible design combinations. Typically, an assumption is made regarding one of the parameters, usually As (. Examples of common design assumptions are: = 0.5b = 0.375b (this corresponds to 0.50max for previous editions of ACI 318) = .01 = 1% The design at this stage is also complicated by the fact that the self-weight of the beam is unknown. Once a design assumption is made, the process of beam design generally relies on one of the design aids presented in the previous section. It is again emphasized that the design aids are identical to the equations derived in the previous section (Equations 3, 4, 5, & 6), such that solution by these equations is essentially identical to solution using design aids. Design Problem (same problem as before with b and d unknown) The beam below supports an indoor walkway on a 20-foot simply-supported span. The superimposed dead load is 1000 lb/ft and the superimposed live load is 1000 lb/ft. Select flexural reinforcement for the beam if the material properties to be used are f 'c = 4000 psi and fy = 60,000 psi. (Ignore the presence of any top bars used to facilitate stirrup placement.) LL = 1.00 k/ft DL = 1.00 k/ft h 20 ft. b 12 Beam self-weight (assume concrete weighs 145 pcf; assume 12"x24" cross-section): 2 1 ft k .145 0.29 k / ft ft 3 12 in 12 in .24 in . DLsw Total factored load: 1.2w D 1.6w L wu 1.21.00 0.29 k / ft 1.61.00 k / ft 3.15 k / ft Total factored moment (design for maximum moment along span): Mu w u2 8 3.15 k / ft 20 ft 2 8 157 .5 ft. kips 1890 in . kips Assume 1.5 in. clear cover, 0.5 in. stirrup, and 1.0" diameter bars d = h - 2.5" Design assumption: 0.375 b fy f c' 0.375.0285 .0107 .0107 60 ksi 4 ksi .1605 Enter design aid ( design aid used here): Mu bd 2 f c' .1453 Solve for required bd2: bd 2 required Mu .1453 f c' 1890 in . kips 3613 in .3 .90 4 ksi .1453 Possible combinations of b and d: b = 10", d = 19" b = 12", d = 17.5" b = 14", d = 16" bd2 = 3610 in.3 bd2 = 3675 in.3 bd2 = 3584 in.3 Note: This calculation gets us "in the ballpark". Selection of a b-d combination that gives us less than the calculated requirement of 3625 in.2 will simply mean that we need a slightly higher reinforcement ratio. Any of these three combinations will therefore work. 13 Try b = 12", h = 20" (d = 17.5") Now, proceed as for a design with b and d known. Beam self-weight (assume concrete weighs 145 pcf): 1 ft 12 in 12 in .20 in . DLsw 2 k .145 3 0.242 k / ft ft Total factored load: wu 1.2w D 1.6w L 1.21.00 0.242 k / ft 1.61.00 k / ft 3.09 k / ft Total factored moment (design for maximum moment along span): Mu w u2 8 3.09 k / ft 20 ft 2 8 154 .5 ft. kips Assume 1.5 in. clear cover, 0.5 in. stirrup, and 1.0" bars 1854 in . kips d = 17.5" Using the design aid based on Equation 6: Mu bd 2 f c' 1854 in . kips .90 12 in .17.5 in .2 4 ksi .1401 Entering PCA Notes table with value of 0.1401, and interpolating linearly: required .1541 required required A s, required f c' fy required bd .1541 4 ksi .0103 60 ksi .0103 12 in .17.5 in . 2.16 in .2 Try 3 #8 bars (As = 2.37 in.2) Check reinforcement limits, analyze section, check cover & spacing as before… (This section works) 14 Design by Simplified Methods Simplified design methods involve the same basic approach as the methods outlined previously, but with further simplifications (i.e. assumptions) that reduce the effort involved in the design process. The method outlined in this section is adapted from the following references: Fanella, D. and Ghosh, S.K. (editors), Simplified Design - Reinforced Concrete Buildings of Moderate Size and Height, Portland Cement Association, Second Edition, 1993. Fanella, D., "Time-saving design aids for reinforced concrete," Structural Engineer, August 2001, pp. 38-41. Consider the simplifying assumption that .375 b (7A) A set of design aids (Tables 1A through 5A) have been developed based on this simplifying assumption. Note: A second set of design aids (Tables 1B through 5B) have been developed based on a similar simplifying assumption: 1 b 2 (7B) Using the assumption of a given as a multiple of b, the values of and are tabulated in Table 1A and 2A (or 1B and 2B) for various combinations of f 'c and fy. A constant C1 can then be calculated where: bd 2 required C1 M u (8) where b and d are in units of inches , and M u is in units of ft kips Equation 8 can be used to help size the cross-section when dimensions have not been established prior to design. 15 The constant C1 can be determined by manipulation of Equation 6: M u bd 2 f ' c bd 2 Mu C1 1 0.59 f c' 1 0.59 1 f c' 1 C1 M u (9) 0.59 Values of C1 are tabulated in Tables 3A and 3B. The value of j, where jd is the length of the moment arm between the resultant internal tensile and compressive forces, can also be computed directly as a function of f 'c and fy: jd j d a 2d 1 j 1 j 1 a 2 Asf y .85 f ' b c 2d 1.7 (10) Values of j are tabulated in Tables 4A and 4B. Finally, a required quantity of reinforcement can be computed based on the following expression: As, required Mu C2 d (11) where d is in units of inches , A s in units of in . , and M u in units of ft kips 2 16 The constant C2 can be determined by manipulation of Equation 2: Mu a A s f y d A s f y jd 2 As C2 f y j Mu f y jd Mu C2d (12) Values of C2 are tabulated in Tables 5A and 5B. Design Problem (same problem as before with b and d unknown) Consider the design example solved previously, and use the design assumption: 0.375 b Note that as before, we assume a self weight for the beam such that Mu = 157.5 ft.-kips: From Table 1A = .0107 From Table 2A = .1604 From Table 3A C1 = 23.0 (bd2)required = 23.0(157.5) = 3623 in.2 Try b = 12", d = 17.5" (h = 20") Correcting our self-weight assumption to the values for the selected beams size, we get Mu = 154.5 ft.-kips: From Table 4A j = 0.906 From Table 5A C2 = 4.08 (As)required = (154.5)/[(4.08)(17.5)] = 2.16 in.2 Try 3 #8 bars (As = 2.37 in.2) Check reinforcement limits, analyze section, check cover & spacing as before… (This section works) Technically, the designer only needs to look up values in Table 3A and Table 5A. The values in tables 1A, 2A, and 4A are only provided for reference. 17 TABLE 1a 0.375b bd C1 M u 2 required where As, required b and d are in units of inches , and M u is in units of ft kips Mu C2 d where d is in units of inches , A s in units of in .2 , and M u in units of ft kips TABLE 2a fy (psi) (corresponding to 0.375b) 40000 50000 60000 75000 3000 3500 4000 4500 5000 6000 7000 8000 9000 10000 11000 12000 0.1856 0.1856 0.1856 0.1801 0.1747 0.1638 0.1528 0.1419 0.1419 0.1419 0.1419 0.1419 0.1721 0.1721 0.1721 0.1670 0.1619 0.1518 0.1417 0.1316 0.1316 0.1316 0.1316 0.1316 0.1604 0.1604 0.1604 0.1556 0.1509 0.1415 0.1321 0.1226 0.1226 0.1226 0.1226 0.1226 0.1455 0.1455 0.1455 0.1412 0.1369 0.1284 0.1198 0.1113 0.1113 0.1113 0.1113 0.1113 TABLE 4a 60000 75000 0.0139 0.0162 0.0186 0.0203 0.0218 0.0246 0.0267 0.0284 0.0319 0.0355 0.0390 0.0426 0.0103 0.0120 0.0138 0.0150 0.0162 0.0182 0.0198 0.0211 0.0237 0.0263 0.0289 0.0316 0.0080 0.0094 0.0107 0.0117 0.0126 0.0141 0.0154 0.0163 0.0184 0.0204 0.0225 0.0245 0.0058 0.0068 0.0078 0.0085 0.0091 0.0103 0.0112 0.0119 0.0134 0.0148 0.0163 0.0178 C1 40000 50000 f 'c (psi) 3000 3500 4000 4500 5000 6000 7000 8000 9000 10000 11000 12000 60000 75000 26.9 23.0 20.2 18.4 17.0 15.0 13.7 12.8 11.4 10.3 9.3 8.5 28.7 24.6 21.6 19.7 18.2 16.1 14.7 13.7 12.2 11.0 10.0 9.2 30.6 26.2 23.0 21.0 19.4 17.1 15.6 14.7 13.0 11.7 10.7 9.8 33.4 28.6 25.1 22.9 21.2 18.7 17.1 16.0 14.3 12.8 11.7 10.7 fy (psi) TABLE 5a fy (psi) j f 'c (psi) 50000 TABLE 3a f 'c (psi) f 'c (psi) 3000 3500 4000 4500 5000 6000 7000 8000 9000 10000 11000 12000 fy (psi) 40000 3000 3500 4000 4500 5000 6000 7000 8000 9000 10000 11000 12000 40000 50000 60000 75000 0.891 0.891 0.891 0.894 0.897 0.904 0.910 0.917 0.917 0.917 0.917 0.917 0.899 0.899 0.899 0.902 0.905 0.911 0.917 0.923 0.923 0.923 0.923 0.923 0.906 0.906 0.906 0.908 0.911 0.917 0.922 0.928 0.928 0.928 0.928 0.928 0.914 0.914 0.914 0.917 0.919 0.924 0.930 0.935 0.935 0.935 0.935 0.935 C2 f 'c (psi) 3000 3500 4000 4500 5000 6000 7000 8000 9000 10000 11000 12000 fy (psi) 40000 50000 60000 75000 2.67 2.67 2.67 2.68 2.69 2.71 2.73 2.75 2.75 2.75 2.75 2.75 3.37 3.37 3.37 3.38 3.39 3.42 3.44 3.46 3.46 3.46 3.46 3.46 4.08 4.08 4.08 4.09 4.10 4.13 4.15 4.18 4.18 4.18 4.18 4.18 5.14 5.14 5.14 5.16 5.17 5.20 5.23 5.26 5.26 5.26 5.26 5.26 18 TABLE 1b 0.5b bd C1 M u 2 required where As, required b and d are in units of inches , and M u is in units of ft kips Mu C2 d where d is in units of inches , A s in units of in .2 , and M u in units of ft kips TABLE 2b fy (psi) (corresponding to 0.5b) 40000 50000 60000 75000 3000 3500 4000 4500 5000 6000 7000 8000 9000 10000 11000 12000 0.2475 0.2475 0.2475 0.2402 0.2329 0.2184 0.2038 0.1892 0.1892 0.1892 0.1892 0.1892 0.2294 0.2294 0.2294 0.2227 0.2159 0.2024 0.1889 0.1754 0.1754 0.1754 0.1754 0.1754 0.2138 0.2138 0.2138 0.2075 0.2012 0.1886 0.1761 0.1635 0.1635 0.1635 0.1635 0.1635 0.1940 0.1940 0.1940 0.1883 0.1826 0.1712 0.1598 0.1484 0.1484 0.1484 0.1484 0.1484 TABLE 4b 60000 75000 0.0186 0.0217 0.0247 0.0270 0.0291 0.0328 0.0357 0.0378 0.0426 0.0473 0.0520 0.0568 0.0138 0.0161 0.0184 0.0200 0.0216 0.0243 0.0264 0.0281 0.0316 0.0351 0.0386 0.0421 0.0107 0.0125 0.0143 0.0156 0.0168 0.0189 0.0205 0.0218 0.0245 0.0272 0.0300 0.0327 0.0078 0.0091 0.0103 0.0113 0.0122 0.0137 0.0149 0.0158 0.0178 0.0198 0.0218 0.0237 C1 40000 50000 f 'c (psi) 3000 3500 4000 4500 5000 6000 7000 8000 9000 10000 11000 12000 60000 75000 21.0 18.0 15.8 14.4 13.3 11.7 10.6 9.9 8.8 7.9 7.2 6.6 22.4 19.2 16.8 15.3 14.2 12.5 11.3 10.6 9.4 8.5 7.7 7.1 23.8 20.4 17.8 16.3 15.0 13.3 12.1 11.3 10.0 9.0 8.2 7.5 25.9 22.2 19.4 17.7 16.4 14.4 13.2 12.3 10.9 9.8 9.0 8.2 40000 50000 60000 75000 2.56 2.56 2.56 2.58 2.59 2.61 2.64 2.67 2.67 2.67 2.67 2.67 3.24 3.24 3.24 3.26 3.27 3.30 3.33 3.36 3.36 3.36 3.36 3.36 3.93 3.93 3.93 3.95 3.97 4.00 4.03 4.07 4.07 4.07 4.07 4.07 4.98 4.98 4.98 5.00 5.02 5.06 5.10 5.13 5.13 5.13 5.13 5.13 fy (psi) TABLE 5b fy (psi) j f 'c (psi) 50000 TABLE 3b f 'c (psi) f 'c (psi) 3000 3500 4000 4500 5000 6000 7000 8000 9000 10000 11000 12000 fy (psi) 40000 3000 3500 4000 4500 5000 6000 7000 8000 9000 10000 11000 12000 40000 50000 60000 75000 0.854 0.854 0.854 0.859 0.863 0.872 0.880 0.889 0.889 0.889 0.889 0.889 0.865 0.865 0.865 0.869 0.873 0.881 0.889 0.897 0.897 0.897 0.897 0.897 0.874 0.874 0.874 0.878 0.882 0.889 0.896 0.904 0.904 0.904 0.904 0.904 0.886 0.886 0.886 0.889 0.893 0.899 0.906 0.913 0.913 0.913 0.913 0.913 C2 f 'c (psi) 3000 3500 4000 4500 5000 6000 7000 8000 9000 10000 11000 12000 fy (psi) 19