Planning Sequential Constant-Stress Accelerated Life Tests with

advertisement

Planning 2-Stage Accelerated Life Tests

LC Tang (董润楨), Ph.D

Department of Industrial and Systems Engineering

National University of Singapore

Overview

• Planning a sequential Accelerated Life Test (ALT)

• Motivation of using an Auxiliary Stress (AS)

• An integrated planning framework for sequential ALT

with an AS

• Numerical illustrations

A Constant-Stress ALT

Time

Probability

distributions

Maximum

Test

Duration

Life-stress

relationship

Use

Stress

Low

Stress

Mid

Stress

High

Stress

Stress Level

A Scale-Accelerated Weibull Lifetime Model

• Standardization of stress x x s s sk s0 sk 1

s0 : use stress sk : the highest stress

• Weibull lifetime distribution at any stress

log T -

SEV

• A scale-accelerated failure time model

0 1 x , 1 0

is a constant independent of stress

Motivations of Sequential ALT Planning

• ALT planning based on the Maximum Likelihood theory

Step 1:

Step 2:

Step 3:

Specify ALT model

parameter values

Minimize the asymptotic

variance of ML estimator

Evaluate the plan

using simulations

• Locally optimal for specified model parameters 0 , 1,

• Problems:

– There often exists a high margin of specification error

– Developed plans are usually sensitive to the specified value

A Framework of Sequential ALT Planning

Information

Planning information

e.g. test duration, specified

parameter values, etc.

Information on the slope

parameter 1

Planning Procedure

Plan & Perform the test at the

highest stress to quickly obtain

failures

Preliminary information on ( 0 , )

Planning information

e.g. test duration, number of

stress levels, sample sizes,

etc.

•

•

Plan the tests at lower stress levels

Tang, L.C. and Liu, X. (2010) “Planning for Sequential Accelerated Life Tests”, Journal of

Quality Technology, 42, 103-118.

Liu, X. and Tang, L.C. (2009) “A Sequential Constant-Stress Accelerated Life Testing Scheme

and Its Bayesian Inference”, Quality and Reliability Engineering International, 25, 91-109.

Part I

Planning Sequential Constant-Stress Accelerated

Life Tests

Sample Size at the Highest Stress Level

Specify

the values of 0 (or H ) and

the censoring time cH

the expected number of failures RH

Sample Size:

RH

p

nH

Page 8

p 1 exp cH / exp( H )

1/

Inference at the Highest Stress Level

Time in log-scale

θH l θH ; DH θH H ,

Stress

0

High

Low

1

Use

Inference at the Highest Stress Level

ˆ )

θˆ H | y H ~ N (θˆ H , Σ

H

where

θˆ H arg max (θ H )

ˆ Iˆ 1

Σ

H

Generalized MLE

Covariance matrix

H

Iˆ H [ 2l (θ H ; D H ) / θ H 2 ]θ

H

θˆ H

Observed information

Page 10

Construction of Prior Distributions

k ,

i , for xi 0,1

H ,

Information on

the value of 1

i k 1 xi

is a constant

Construction of Priors at Low Stresses

for any i 1,..., H 1, there exists a one-one transformation θi (θH )

with non-vanishing Jacobian θH / θi ,such that

1

(θi ) ( i 1 xi , )

1

1 ~U ( 1 , 1 )

( i 1 xi )

dF ( 1 )

i

( i ˆ H ) 2

erf ( i ) erf ( i )

exp

ˆ

23/ 2 ( var(ˆ H ))1/ 2 (i i )

2

var(

)

H

where

i ˆ H 1 xi , i ˆ H 1 xi , i ˆ H 1 xi , cov(ˆ H , ˆ H ) / var1/ 2 ( ˆ H ) var1/ 2 (ˆ H )

i var1/ 2 (ˆ H ) i var1/ 2 (ˆ H ) ( i ˆ H ) var1/ 2 ( ˆ H )

(2 var( ˆ H ) var(ˆ H )(1 2 ))1/ 2

i

i var1/ 2 (ˆ H ) i var1/ 2 (ˆ H ) ( i ˆ H ) var1/ 2 ( ˆ H )

(2 var( ˆ H ) var(ˆ H )(1 2 ))1/ 2

i

Page 12

Illustration of the Sequential ALT

Plan & Run the

test at the highest

stress

Time in log-scale

Deduction of Prior

Distributions

Stress

0

High

Page 13

Low

1

Use

Pre-Posterior

Analysis &

Optimization

The Bayesian Optimization Criterion

Given the information obtained under the highest stress, the

optimum sample allocation and stress combinations for tests

under lower stresses are chosen to minimize the pre-posterior

expectation of the posterior variance of certain life percentile

under use stress over the specified range of β1

Min C (ξ ) = E1 {var( y p (1))}

= E1 {c var(θ0 )cT } c [1, log( log(1 p))]

Page 14

Problem Formulation

Design Matrix

X 1

x1

1

xH 1

1

xH

T

E1 (var( y p ( x1 )))

Λ

E1 (var( y p ( xH 1 )))

var( y p (0))

Min E1 (var( y p (1))) 1( XT Λ 1X) 11T

s.t.

x {( x1 , x2 ,..., xH 1 )

π {(1 , 2 ,..., H )

H 1

H

: 0 xi 1} and xH 0

: i i 1 and 0 i 1}

Page 15

Pre-Posterior Analysis

1

E1 (var( y p ( xi )))

1 1

Σ i I θi I

1

1

cΣi cd 1

i 1

where

2 log l θi

2 log l θi

I θi E

; y

f y dy

2

2

θi

θi

2

log θ i

i

I

θi 2

Page 16

Information

contained in

the prior

density

Information

expected to

obtain at

stress level i

Adhesive Bond Test (Meeker and Escobar 1998)

• Total Sample Size: 300

• Total Testing Duration: 6 months =183days

• Standardized Testing Region: 0 xH x xU 1

• Assumptions:

log(T ) ~ SEV ,

log A

Activation energy, Ea

1

Boltzmann constant, k B 8.6171105 T

(Arrhenius)

0 1 x,

is a constant

Page 17

0 log A Ea k B 1 sH , 1 Ea k B 1 ( s0 sH )

Planning at the Highest Temp

Planning

information:

H 4.72

0.6

RH 15

cH 60

50 samples are needed

Page 18

RH nH p

Posterior Density

Simulated Failure times:

33.3, 48.4, 39.3, 58.8, 47.4, 60.0, 33.6, 19.4, 38.0, 28.6, 60.0, 53.2, 17.7, 25.4, 44.5,

34.6, 16.9, 60.0, 31.7, 60.0 ,49.2, 60.0, 10.953, 60.0, 18.8, 3.3, 1.4, 17.3, 46.8, 40.9,

60.0, 28.4, 60.0, 4.2, 21.9, 49.6, 20.6, 60.0, 46.6, 6.4, 25.2, 60.0, 13.6, 29.5, 60.0,

60.0, 31.3, 29.4, 54.3, 34.0

Page 19

Normal Approximation

ˆ )

θˆ H | data ~ N (θˆ H , Σ

H

ˆ Iˆ 1 and Iˆ [ 2l (θ ) / θ 2 ]

where Σ

H

H

H

H

H θ

H

θˆ H

Page 20

Planning of an ALT with 2 Stress Levels

Sample size

nL 300 nH 250

100

Test duration

cL 183 cH 123

Posterior density at xH

ˆ

θ H | y H ~ N θˆ H , Σ

H

Specified range of 1

1 3.84,5.12

(i.e.Ea 0.6, 0.8)

E1 var y p 1 in log-scale

Planning Information:

10

1

0.1

0.01

0.1

0.2

0.3

0.4

High

0.5

0.6

xL

0.7

0.8

0.9

1

Low

Page 21

Effects of the pre-specified slope parameter

Suppose we raise the expectation of the product reliability

Ea 0.6,0.8 Ea 0.6,0.9 i.e. 1 3.84,5.12 1 3.84,5.76

E1 var y p 1 in log-scale

Effect:

100

10

Beta1 ranges from

3.84 to 5.76

1

0.1

Run the test under a

higher stress to

produce more

failures

Beta1 ranges from

3.84 to 5.12

0.01

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

High

xL

Low

Page 22

Plan an ALT with 3 stress levels

Planning Information:

Min E1 (var( y0.1 (1)); xL , )

nL 250, cL 123

H , , 1 3.84,5.12

s.t.

nL M (1 ) p ( xL ) RL

Additional constraints:

nL M p ( xM ) RM

nL 250 (1 )

0 x H x L 2 xM 1

nM 250

xM

for 0 1

0 1

xL

2

Minimum number of failure

RL and RM

where

p( xL )

(1 exp( exp( ))) ( , )d d

) (1 exp( exp( ))) ( , )d d

L

0

p( xM

L

L

L

L

0

M

M

M

M

Page 23

M

The feasible region

Page 24

Interior Penalty Function Method

Page 25

Page 26

Inference from Test Results

Simulated failure times (assume 0 4, 1 4, 4)

Stress

Sample

Test

Expected

Simulated

Observed

Level

Size

Duration

Failures

Failure Times

Failures

15

33.3, 48.4, 39.3, 58.8, 47.4, 60.0, 33.6, 19.4, 38.0,

28.6, 60.0, 53.2, 17.7, 25.4, 44.5, 34.6, 16.9, 60.0,

31.7, 60.0 ,49.2, 60.0, 10.953, 60.0, 18.8, 3.3, 1.4,

17.3, 46.8, 40.9, 60.0, 28.4, 60.0, 4.2, 21.9, 49.6,

20.6, 60.0, 46.6, 6.4, 25.2, 60.0, 13.6, 29.5, 60.0,

60.0, 31.3, 29.4, 54.3, 34.0

38

High

xH 0

Mid

xM 0.39

Low

xL 0.78

50

20

230

60

123

123

5

46.1 62.5 86.2 98.9 101.7 123

(×224)

5

5

22.8 44.8 59.1 84.4 87.7

105.2 123 (×224)

6

Page 27

Inference

• Results obtained under the high stress

H ,

0.0112 0.0003

~ N 3.87, 0.65 ,

0.0003

0.0086

• Results obtained under the mid and low stress

M ,

Increasing

Decreasing

0.0156 0.0016

~ N 5.28, 0.594 ,

0.0016

0.0080

L ,

0.0377 0.0060

~ N 7.24, 0.664 ,

0.0060

0.0042

Simulation Study

Planning information:

Total Sample Size: 300

Total Test Duration: 183

Pre-specified ALT model parameters: 9 scenarios are considered

*For sequential plans:

We set the expected number of failures at the high stress level

at 15 within 60 days

*For each simulation scenario:

a. both sequential and non-sequential plans are generated;

b. failure data are generate according to the optimum plans;

c. 10th percentile are use stress are estimated;

d. repeat b and c for 100 times, and move to another scenario

Page 29

Simulation Design Table

- k %: the specified value is k% lower than the true value

+k %: the specified value is k% higher than the true value

(0):

the specified value is the true value

Scenarios

Pre-specified

Pre-specified

Pre-specified 1

Pre-specified 1

(non-sequential)

(sequential)

0

1

(0)

(0)

(0)

- 20 % ~ + 20 %

2

- 25 %

- 25 %

- 20 %

- 20 % ~ + 20 %

3

- 25 %

- 25 %

+ 20 %

- 20 % ~ + 20 %

4

- 25 %

+ 25 %

- 20 %

- 20 % ~ + 20 %

5

- 25 %

+ 25 %

+ 20 %

- 20 % ~ + 20 %

6

+ 25 %

- 25 %

- 20 %

- 20 % ~ + 20 %

7

+ 25 %

- 25 %

+ 20 %

- 20 % ~ + 20 %

8

+ 25 %

+ 25 %

- 20 %

- 20 % ~ + 20 %

9

+ 25 %

+ 25 %

+ 20 %

- 20 % ~ + 20 %

Page 30

Simulation Results

Page 31

Precision

1. Sequential plans yields more precise estimation

Variance

2. Sequential plans gives a conservative sense of statistical

precision: Sample variance > Asymptotic variance

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

Sample variance

(non-sequential plan)

Asymptotic variance

(sequential plan)

Sample variance

(sequential plan)

0

Page 32

Asymptotic variance

(non-sequential plan)

1

2

3

4

5

6

7

Simulation scenarios

8

9

10

Effect of Parameter Mis-specification on Precision

Sequential Plans

Non-sequential Plans

Effect on

the

expected

variance

Effect on

the

observed

variance

0.270

0.1945

0.016

-0.2075

0.044

0.043

-0.007

-0.1180

For sequential plan:

0.083

0.0655

Since

0.035

0.0185

1.

-0.031

-0.009

Model parameters 0 and are

estimated at stage one;

For non-sequential plan:

2.

An interval value of 1 is used

Results are sensitive to the specified

model parameters 0 and 1 .

Hence, the plan robustness to the misspecification of model parameters

Page 33

has been enhanced

0

1

0 * 1

0 *

1 *

0 * 1 *

Effect on the

expected

variance

Effect on the

observed

variance

0

-0.053

-0.038

(0, 0.0001)

(- 0.0001,0)

0 *

(- 0.0001,0)

(- 0.0001,0)

Robustness

Define the Relative Error (RE) as:

sample variance - asymptotic variance asymptotic variance

3. Sequential plans is more robust to mis-specification of model

parameters

2.5

RE

(non-sequential plan)

2

RE

1.5

RE

1

(sequential plan)

0.5

0

0

Page 34

1

2

3

4

5

6

7

Simulation scenarios

8

9

10

Effect of Parameter Mis-specification on the Relative Error (RE)

Non-sequential Plans

Sequential Plans

Effect

0

1

0 * 1

0 *

1 *

0 * 1 *

Effect

0

-0.7684

0 *

-0.7187

-0.2367

0.0011

(0, 0.0001)

(0, 0.0001)

0.4905

0.1334

For sequential plan:

0.1201

Since

-0.0532

1.

Model parameters 0 and are

estimated at stage one;

For non-sequential plan:

2.

An interval value of 1 is used

RE is sensitive to the pre-specified

model parameters 0 and 1 .

Hence, the plan robustness to the misspecification of model parameters

has been enhanced

Page 35

Simulation Results

4. Sequential plans reduce the degree of extropolation;

5. Sequential plans are especially robust to mis-specification of the

intercept parameters (scenarios 6-9) due to the preliminary test

under the high stress

Optimum low stress

(non-sequential plan)

120

Temperature

100

80

60

40

20

Use stress

Optimum low stress

(sequential plan)

0

0

Page 36

1

2

3

4

5

6

7

Simulation scenarios

8

9

10

Effect of Parameter Mis-specification on the Optimum Low Stress level

Non-sequential Plans

Sequential Plans

Effect

0

1

0 * 1

0 *

1 *

0 * 1 *

Effect

0

12.25

0 *

-13.25

3.25

-5

(- 0.0001,0)

(- 0.0001,0)

-1.25

3.25

For sequential plan:

1.75

Since

0.75

1.

Model parameters 0 and are

estimated at stage one;

For non-sequential plan:

2.

An interval value of 1 is used

RE is sensitive to the pre-specified

model parameters 0 and 1 .

Hence, the plan robustness to the misspecification of model parameters

has been enhanced

Page 37

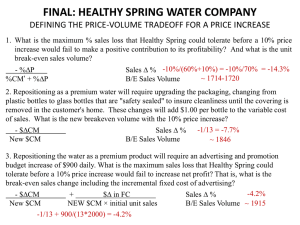

Comparison with 4:2:1 Plan

ASR

c:

|Ase Ase when model parameters are correctly specified|

Ase when model parameters are correctly specified

Test duration at the highest stress level

Extension from 2-Stage Planning to a Full

Sequential Planning

•

•

•

•

•

2-Stage Planning

Prior distributions for all low stresses are constructed

simultaneously (all-at-one)

Tests at all low stresses are planned simultaneously

Full Sequential Planning

Only the prior distribution for one low stress is constructed

Only the test at one low stresses are planned

More tests at low stresses are planned iteratively

The basic framework still works !

Part II

Planning Sequential Constant-Stress Accelerated Life Tests

with

Stepwise Loaded Auxiliary Stress

Liu X and Tang LC (2010), “Planning sequential constant-stress accelerated life tests with

stepwise loaded auxiliary acceleration factor”, Journal of Statistical Planning and Inference,

140, 1968-1985.

Motivations of an Auxiliary Stress

• Testing more units near the use condition is intuitively

appealing, because more testing is being done closer to the use

condition

• Failures are elusive at low stress levels for highly reliable

testing items

– the lowest stress level is forced to be elevated, resulting in high,

sometimes intolerable, degree of extrapolation in estimating product

reliability at use stress

Illustration

Low degree of extrapolation

with zero failure

Time

high degree of extrapolation

with more failures

Maximum

Test

Duration

Use

Stress

Candidate low

stress 1

Candidate low

stress 2

High

Stress

Stress Level

Auxiliary Stress

• An Auxiliary Stress (AS), with roughly known effect on product life, is

introduced to further amplify the failure probability at low stress levels

• Examples of possible AS:

– In the reliability test of micro relays operating at difference levels of

silicone vapor (ppm), the usage rate (Hz) might be used as an auxiliary

factor (Yang 2005).

– In the temperature-accelerated life test, the humidity level controlled in

the testing chamber might be used as an AS (Livingston 2000).

– Dimension of testing samples (Bai and Yun 1996)

• Joseph and Wu (2004) and Jeng et al. (2008) proposed a method known as

the Failure Amplification Method (FAMe) for the Design of Experiments.

– FAMe was developed for system optimization while ALT is used for

reliability estimation at user condition through extrapolation.

Model Extension

• Standardization of the level of AS

h (v vuse ) (vmax vuse )1

vuse : use stress vmax : the highest stress

• The extended testing region: [0,1]2

• A scale-accelerated failure time model

0 1 x 2 h

is a constant independent of stress

Examples:

Hallberg-Peck model

Higher usage rate model (Yang 2005)

An Integrated Framework of Sequential ALT Planning

with an Auxiliary Stress

Planning Information

e.g. Sample size; Test

duration; Specified model

parameters

Step 1: Plan and perform the life

test at the highest stress level

Step 2: Compute the number of

failures at low stresses

Is an AS needed?

No

yes

Is an AS available?

yes

Step 3b: Plan the tests at low

stresses with an AS

i.e. optimize sample allocation,

stress combinations, and the

loading profile of AS

No

Step 3a: Plan the tests at low

stresses without an AS

i.e. optimize sample allocation,

and stress combinations

Step 1

Planning & Inference

at the Highest Temperature Level

ALT for Electronic Controller

Experiment Target:

To demontrate the 10% life quantile at use condition exceeds 2 years

Stress Factor:

Temperature (other factors, such as humidity, voltage, etc are set to use level)

Planning information and Assumptions:

1). 120 sample units and 75 days are available.

2). The use temperature is 450 C 318K

The highest temperature allowed in the test is 850 C 358K

3). Failure time T follows Weibull distribution

F t log t

4). is a constant, independent of temperature; follows Arrhenius stress-life

relationship

i log A

Activation energy, Ea 1

0 1 si

Boltzmann constant, k B Ti

where 0 log A 1 Ea si 11605 / Ti

Test Planning at the Highest Stress

Planning Inputs:

target number of failures: rk

1/

k

Rk exp ck exp

parameter values: k ( 0 ),

confidence level:

censoring time: ck

Planning Output: nk

rk 1

C

i 0

i

nk

nk i

1

R

R

k k 1

i

Risk of see less

failures than expected

(Binomial Bogey test, Yang 2007)

Testing Output: ˆ H ( ˆ0 ) or ˆ

Results

Planning

information:

k 7.5

0.677

rk 6

ck 720hr

0.9

44 samples are needed

Data Obtained at the Highest Stress

Weibull Probability Plot for

Observed Failure Data

Time-to-failure (hours)

79.559 210.47

400.56 491.41

673.98

109.4

204.7

425.32

117.15 328.99

720×29

Note: This is just a

particular run

590.03

138.94

149.95

643.31

351.87

0

-0.5

-1

-1.5

-2

-2.5

R² = 0.8995

1.7

2.2

2.7

3.2

Statistical Inference at the Highest Stress

Posterior distribution derived from a constant prior :

θk ; y l θk ; y

y j k

1 y j k

ck k

exp j log

exp

1

exp

j

j 1

where θk ( k , ); 0 if the data is censored, otherwise 1

nk

Normal Approximation to the Posterior distribution (Berger 1985)

ˆ ) N (θˆ ,[ Iˆ ]1 )

θ k y ~ N (θˆ k , Σ

k

k

k

where

2

ˆI = l (θ k ; y )

k

θ k 2 θ

(observed Fisher information at θˆ k )

k

θˆ k

0.0529

ˆ Iˆ 1 0.1142

θˆ k [7.35, 0.90] Σ

k

k

symmetric 0.0489

Illustration

• The quality of the approximation needs to be checked

e.g. Kolmogorov-Smirnov (K-S) test (Martz et.al 1988, Technometrics).

• The posterior normality needs to be checked

e.g. Kass and Slate 1994 Ann. Statist. ).

Step 2

Computation of the Expected Number of

Failures at Low Stress Levels

Construction of Prior Distributions

k ,

i , for xi 0,1

H ,

Information on

the value of 1

i k 1 xi

is a constant

Density Function of the Constructed Prior

1

i , ( i 1 xi , )

1

( i 1 xi )

( 1 )d 1

i

( ˆ ) 2

1

3/ 2

exp

erf ( i ) erf ( i )

1/ 2

2 ( var(ˆ )) (i i )

2 var(ˆ )

i 1,..., k 1

where ( 1 ) is a uniform distribution defined on an interval [1 ,1 ]

erf is the error function given by the definite integral erf ( z ) 2

1/ 2

z

0

e t dt

i ˆ k 1 xi

i ˆ k 1 xi , i ˆ k 1 xi , cov( ˆ k , ˆ ) / var1/ 2 ( ˆ k ) var1/ 2 (ˆ )

i var1/ 2 (ˆ ) i var1/ 2 (ˆ ) ( ˆ ) var1/ 2 ( ˆ k )

(2 var( ˆ k ) var(ˆ )(1 2 ))1/ 2

i

i var1/ 2 (ˆ ) i var1/ 2 (ˆ ) ( ˆ ) var1/ 2 ( ˆ k )

(2 var( ˆ k ) var(ˆ )(1 2 ))1/ 2

i

2

Illustration of the Constructed Priors at

65⁰C and 45⁰C

Let Ea 0.8,1.2, i.e 1 ~ Uniform0.8,1.2

Uncertainty over becomes larger for lower testing temperature

Expected Number of Failures at Low Stress

In order to see 5 failures, the

temperature is almost on the middle

of the testing region !!

Another Point of View:

Prior Information v.s Information To Be Obtained

det I θi

det Ii

2l (θi )

2 log (θi )

where I θi =E

and I θi =

2

θi 2

θi

Information to be

obtained by performing

a test at stress level i

Little

Information

obtained from

low temp

“Information”

contained in the

prior knowledge

Step 3

Planning at the Lower Temperature Level

With Auxiliary Stress

•The choice of AS

•The loading of AS

•The integration of AS in test planning

The Choice of AS

Assumpotions:

1). The effect of AS is well understood

2). The failure mode does NOT change after an AS is introduced

Auxiliary Stress: Humidity

Hallberg-Peck Model (Livingston, 2000):

RH j

0 1s p log

RH

0

RH 0 : use humidity level, 60%

RH : humidity level in test ( 90%)

The Choice of Loading Profile for AS

ConstantStress Loading

Step-Stress

Loading

A 2-step step-stress loading profile is preferred due to the following

reasons:

• The initial loading will not be too harsh

• The stress can be dynamically monitored given a target time

compression factor (only amplify the failure as needed)

• The verification of the effect of the selected AS is possible

Setting a Target Acceleration Factor

equivalent test duration, ci(e)

Time Compression Factor: i

actual test duration, ci

LCEM Cumulative Exposure Model

(Yeo and Tang 1999, Tang 2003)

A Bayesian Planning Problem

Min E1 (var( y p (1))) 1( XT Λ 1X) 11T

s.t.

target time compression i , for i 1,..., k 1

( x1 , x2 ,..., xk 1 ) [0,1]k 1

Stress levels

(1 , 2 ,..., k 1 ) [0,1]k 1 : i 1 i 1 k

Sample allocation

(h1 , h2 ,..., hk 1 ) [0,1]k 1

Initial level of AS

( 1 , 2 ,..., k 1 ) [0, c]k 1

Stress changing time for AS

k 1

where

T

1

1 1

X

x

x

x

k

1 2

0

E1 (var( y p ( x1 )))

0

E1 (var( y p ( x2 )))

Λ

0

0

0

0

0

0

var( y p ( xk ))

0

Planning Results

Planning Information:

Sample size

n1 120 n2 76

Test duration

c1 1800 720 1080

Posterior density at xH

θ 2 ~ N θˆ 2 , Iˆ 1 θ2

1 ~ Uniform 0.8,1.2

p3

Maximum RH = 90%

Use RH = 60%

3

Testing

Condition

Temp

(C)

RH

(%)

Use

45

60

Low

53

High

85

Testing

Duration

Sample

Size

See

Profile

1080hrs

76

60

720hrs

44

Humidity Loading Profile at Low Temperature

Low Humidity Level: 60%

High Humidity Level: 90%

Holding Time: 170.5 hrs

Expected Failures:

Interval [0, 170.5] : No

failure

Interval [170.5,1080]: 5

failures

Interval [1080, ): 71 censored

Illustration: ALT without AS

Relative

Humidity

Point B: (53, 60%)

Failure Probability < 0.01

Point A: (85, 60%)

Failure Probability = 0.32

60%

Temperature

53

85

Illustration: ALT with AS

Relative

Humidity

Point D: (53, 90%)

Failure Probability = 0.08

90%

Point C: (53, 60%)

Failure Probability < 0.01

Point A: (85, 60%)

Failure Probability = 0.32

60%

Temperature

53

85

Sensitivity of the Optimal Plan to p

RHT:

Relative change

of low humidity

holding time

RT/RH

Relative change of

low humidity/low

temperature

RSD:

Relative change of

Asymptotic SD

Sensitivity of the Plan to

the Activation Energy

RHT:

Relative change

of low humidity

holding time

RT/RH

Relative change of

low humidity/low

temperature

RSD:

Relative change of

Asymptotic SD

Evaluation of the Developed ALT Plan

References of Part II

• Liu X and Tang LC (2010), “Planning sequential constantstress accelerated life tests with stepwise loaded auxiliary

acceleration factor”, Journal of Statistical Planning and

Inference, 140, 1968-1985.