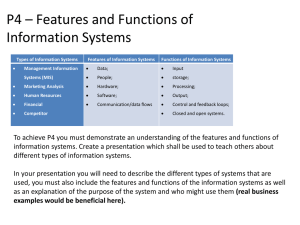

In control - U

advertisement

1

QUALITY CONTROL

Chapter 10

MIS 373: Basic Operations Management

Additional content from Jeff Heyl

LEARNING OBJECTIVES

• After this lecture, students will be able to

1.

2.

3.

4.

Explain the need for quality control.

List and briefly explain the elements of the control process.

Explain Type I and Type II errors

Explain how control charts are used to monitor a process and the

concepts that underlie their use.

MIS 373: Basic Operations Management

2

BACKGROUND KNOWLEDGE

• How many of you have had at least one statistics course?

• Normal distribution?

• Standard deviation?

• Z score?

MOTIVATIONS

• Making Beer Better With Quality and Statistics

• http://videos.asq.org/making-beer-better-with-quality-and-statistics

• Quality for Life: Psychic Pizza

• http://videos.asq.org/quality-for-life-psychic-pizza

WHAT IS QUALITY CONTROL?

• Quality Control

• A process that evaluates output relative to a standard and takes

corrective action when output doesn’t meet standards

• If results are acceptable no further action is required

• Unacceptable results call for correction action

• Phases of Quality Assurance

MIS 373: Basic Operations Management

5

INSPECTION

• Inspection

• An appraisal activity that compares goods or services to a standard

• Inspection issues:

1. What to inspect

• Count number of times defect occurs

• Measure the value of a characteristic

2. How much to inspect and how often

3. At what points in the process to inspect

•

•

•

•

Raw materials and purchased parts

Finished products

Before a costly operation

Before an irreversible process

• Costly, possibly destructive, and disruptive – non value-adding

• Full inspection vs. Sampling

MIS 373: Basic Operations Management

6

HOW MUCH TO INSPECT

MIS 373: Basic Operations Management

7

HOW MUCH TO INSPECT

1 defect in

Trying to catch: 1 thousand

unites

MIS 373: Basic Operations Management

1 defect in

1 million

unites

1 defect in

1 billion

unites

8

CENTRALIZED VS. ON-SITE

INSPECTION

• Effects on cost and level of disruption are a major issue in

selecting centralized vs. on-site inspection

• Centralized

• Specialized tests that may best be completed in a lab

• More specialized testing equipment

• More favorable testing environment

• On-Site

• Quicker decisions are rendered

• Avoid introduction of extraneous factors

• Quality at the source

MIS 373: Basic Operations Management

9

STATISTICAL PROCESS

CONTROL (SPC)

• Quality control seeks

• Quality of Conformance

• A product or service conforms to specifications

• A tool used to help in this process:

• SPC

• Statistical evaluation of the output of a process

• Helps us to decide if a process is “in control” or if corrective action

is needed

• “In control” means that the variation in the provided

products/services is tolerable

MIS 373: Basic Operations Management

10

PROCESS VARIABILITY

• Two basic questions: concerning variability:

1. Issue of Process Control

• Are the variations random? If nonrandom variation is present, the

process is said to be unstable.

Variations randomly distributed within control limits

2. Issue of Process Capability

• Given a stable process, is the inherent variability of the process

within a range that conforms to performance criteria?

The control limits satisfy the design specification

MIS 373: Basic Operations Management

11

VARIATION

• Variation

• Random (common cause) variation:

• Natural variation in the output of a process, created by countless

minor factors

• Assignable (special cause) variation:

• A variation whose cause can be identified.

• A nonrandom variation

• Illustration: M&M’s

• Size

• Color

MIS 373: Basic Operations Management

12

VARIATION

• Common cause

•

•

•

•

•

•

•

•

•

•

•

•

Inappropriate procedures

Poor design

Poor maintenance of machines

Lack of clearly defined

standard operating procedures

Poor working conditions, e.g.

lighting, noise, dirt,

temperature, ventilation

Substandard raw materials

Measurement error

Quality control error

Vibration in industrial

processes

Ambient temperature and

humidity

Normal wear and tear

Variability in settings

MIS 373: Basic Operations Management

• Special cause

•

•

•

•

•

•

•

•

•

•

•

•

•

Poor adjustment of equipment

Operator falls asleep

Faulty controllers

Machine malfunction

Fall of ground

Computer crash

Poor batch of raw material

Power surges

High healthcare demand from

elderly people

Broken part

Abnormal traffic (click fraud) on

web ads

Extremely long lab testing

turnover time due to switching to

a new computer system

Operator absent

13

SAMPLING AND SAMPLE

DISTRIBUTION

• SPC involves periodically taking samples of process

output and computing sample statistics:

• Sample means

• The number of occurrences of some outcome

• Sample statistics are used to judge the randomness

of process variation

MIS 373: Basic Operations Management

14

SAMPLING AND SAMPLE

DISTRIBUTION

• Sampling Distribution

• A theoretical distribution that describes the random

variability of sample statistics

• The normal distribution is commonly used for this purpose

• Central Limit Theorem

• The distribution of sample averages tends to be normal

regardless of the shape of the underlying process

distribution

MIS 373: Basic Operations Management

15

DEMO

• Use simulation to test the Central Limit Theorem

THE NORMAL DISTRIBUTION

MIS 373: Basic Operations Management

17

CONTROL PROCESS

• Sampling and corrective action are only a part of the control

process

• Steps required for effective control:

•

•

•

•

•

•

Define: What is to be controlled?

Measure: How will measurement be accomplished?

Compare: There must be a standard of comparison

Evaluate: Establish a definition of out of control

Correct: Uncover the cause of nonrandom variability and fix it

Monitor results: Verify that the problem has been eliminated

MIS 373: Basic Operations Management

18

CONTROL CHARTS:

THE VOICE OF THE PROCESS

• Control Chart

• A time ordered plot of representative sample statistics obtained from

an ongoing process (e.g. sample means), used to distinguish

between random and nonrandom variability

• Control limits

• The dividing lines between random and nonrandom deviations from the

mean of the distribution

• Upper and lower control limits define the range of acceptable variation

• Upper control limit = UCL = mean + zσ

• Lower control limit = LCL = mean + zσ

MIS 373: Basic Operations Management

19

CONTROL CHART EXAMPLE

Variation

due to

assignable

causes

Out of

control

UCL

Variation due to

natural causes

Mean

LCL

| | | | | | | | | | | |

1 2 3 4 5 6 7 8 9 10 11 12

Sample number

Out of

control

Variation

due to

assignable

causes

• Each point on the control chart represents a sample of n observations

MIS 373: Basic Operations Management

20

ERRORS

• Type I error

• Narrow control limits

• Concluding a process is not in

control when it actually is.

• Manufacturer’s Risk

• Type II error

• Wide control limits

• Concluding a process is in

control when it is not.

Process

In-Control

Process

Out-of-Control

Alarm

No Alarm

Type I

no-error

no-error

Type II

• Consumer’s Risk

MIS 373: Basic Operations Management

21

ERRORS ILLUSTRATION

• Q: I always get confused about Type I and II errors. Can you

show me something to help me remember the difference?

Source: Effect Size FAQs by Paul Ellis

CONTROL CHARTS

Out of Control

In Control

Improved

UCL

LCL

• Every process displays variation in performance: normal or abnormal

• Control charts monitor process to identify abnormal variation

• Do not tamper with a process that is “in control” with normal variation

• Correct an “out of control” process with abnormal variation

• Control charts may cause false alarms – too narrow - (or missed signals –

too wide) by mistaking normal (abnormal) variation for abnormal (normal)

variation

MIS 373: Basic Operations Management

23

CONTROL CHARTS

• Data that are measured

• “x-bar” charts (Mean)

• Used to monitor the central tendency of a process.

• R charts (Range)

• Used to monitor the process dispersion

MIS 373: Basic Operations Management

24

X-BAR (SAMPLE AVERAGE) CHART

CONTROL LIMITS

𝑥

)

𝑘

𝑥 = 𝑥𝑥 = 𝜇𝑥 (=

k = number of samples

𝜎𝑥

𝜎𝑥 =

𝑛

n = sample size

𝑈𝐶𝐿𝑥 = 𝑥 + 𝑧𝜎𝑥 = 𝜇𝑥 + 𝑧 𝜎𝑛𝑥

𝐿𝐶𝐿𝑥 = 𝑥 − 𝑧𝜎𝑥 = 𝜇𝑥 + 𝑧 𝜎𝑛𝑥

commonly: z = 3

𝑈𝐶𝐿𝑥 = 𝑥 + 3𝜎𝑥 = 𝜇𝑥 + 3 𝜎𝑛𝑥

𝐿𝐶𝐿𝑥 = 𝑥 − 3𝜎𝑥 = 𝜇𝑥 + 3 𝜎𝑛𝑥

MIS 373: Basic Operations Management

25

X-BAR CHART

• Mean = 5.5.

• STD = 0.4 ft

6.5

• 99.74% within ± 3 STD

4.3

• 𝑥 ∓ 3𝜎 = 5.5 ∓ 3 ∗ 0.4 = [4.3,6.7]

5.1

5.5

5.9

6.7

5.5

•

(random) 9 students {6.5, 6.4, 6.6, 6.3, 6.7, 6.5, 6.6, 6.4, 6.5} each

within “normal” average = 6.5 ft

•

Sample control limits tighter than population

𝜎

=

𝑛

5.5 + 3

.4

=5.9

9

•

UCL= 𝑥 + 3

•

GROUP above “normal” (outside control limits)

MIS 373: Basic Operations Management

ft.

26

R-CHART: CONTROL LIMITS

• Range charts or R-charts are used to monitor process

dispersion

R Chart Control Limits

UCLR D4 R

LCLR D3 R

where

D3 a control chart factor based on sample size, n

D4 a control chart factor based on sample size, n

MIS 373: Basic Operations Management

27

MEAN AND RANGE CHARTS

(a)

These

sampling

distributions

result in the

charts

below

(Sampling mean is

shifting upward but

range is consistent)

UCL

x-chart

LCL

UCL

R-chart

LCL

MIS 373: Basic Operations Management

(x-chart

detects shift in

central

tendency)

(R-chart does not

detect change in

mean)

28

MEAN AND RANGE CHARTS

(b)

These

sampling

distributions

result in the

charts

below

(Sampling

mean is

constant but

dispersion is

increasing)

UCL

x-chart

LCL

UCL

R-chart

LCL

MIS 373: Basic Operations Management

(x-chart does not

detect the

increase in

dispersion)

(R-chart detects

increase in

dispersion)

29

RUN TESTS

• Even if a process appears to be in control, the data

may still not reflect a random process

• Analysts often supplement control charts with a run

test

• Run test

• A test for patterns in a sequence

• Run

• Sequence of observations with a certain characteristic

MIS 373: Basic Operations Management

30

RUN TESTS

A: Above

B: Below

U: Upward

D: Downward

MIS 373: Basic Operations Management

31

PATTERNS IN CONTROL CHARTS

UCL

UCL

Target

Target

LCL

LCL

Normal behavior. Process

is “in control.”

UCL

Target

LCL

Two plots very near

lower (or upper) control.

MIS 373: Basic Operations Management

One plot out above (or

below). Process is “out of

control.”

UCL

Target

LCL

Trends in either direction, 5

plots. Progressive change.

UCL

UCL

Target

Target

LCL

Run of 5 above (or below)

central line.

LCL

Erratic behavior.

32

DEMO

• ASQ Control chart template

• http://asq.org/learn-about-quality/data-collection-analysistools/overview/asq-control-chart.xls

KEY POINTS

• All processes exhibit random variation. Quality control's

purpose is to identify a process that also exhibits nonrandom

(correctable) variation on the basis of sample statistics (e.g.,

sample means) obtained from the process.

• Control charts and run tests can be used to detect

nonrandom variation in sample statistics. It is also advisable

to plot the data to visually check for patterns.

MIS 373: Basic Operations Management

34