Chapter 1 Lecture Quality Control

advertisement

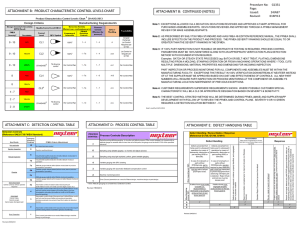

MANUFACTURING OF PHARMACEUTICALS Roselyn Aperocho-Naranjo USPF-College of Pharmacy rose_may26@yahoo.com www.roselynnaranjo.vze.com Chapter 1 ORGANIZATIONAL CHART OF A MANUFACTURING COMPANY BOARD OF DIRECTORS / TRUSTEES PRESIDENT VICE-PRESIDENT GENERAL MANAGERS Personnel Department Coordinates Finance Department Marketing Department Technical Director Plant Department Cost Accounting Market Research Research & Product Development Production Labor & Warehouse Budget Sales & Detailing Management General Accounting Relationship Advertising Quality Control of Drugs & Cosmetics Manufacture of Pharmaceuticals Maintenance ORGANIZATIONAL CHART OF A PLANT DEPARTMENT PRODUCTION CONTROL DIVISION Planning & Scheduling Section Purchasing Section Inventory Section WAREHOUSE DIVISION Raw Materials In-process section Finished Goods Returned Goods Dispensing Section ORGANIZATIONAL CHART OF A PLANT DEPARTMENT WAREHOUSE DIVISION Raw Materials Quarantine Area Approved for Use Rejected Goods Area PRODUCTION / MANUFACTURING DEPARTMENT Extractives Liquids Tablets, Capsules Parenterals, Ophthalmic Medicated Application Powders, Aerosols MANUFACTURING OF PHARMACEUTICALS CLASSIFICATION OF PHARMACEUTICALS MEDICATED APPLICATIONS Ointments Cataplasm (Poultices) Cements Ceratose Creams Dressings Pastes Plasters Suppositories LIQUIDS Solutions Emulsions Suspensions EXTRACTIVES Tinctures Fluid Extracts Extract Resins Oleoresins POWDERS & AEROSOLS TABLES, CAPSULES AND PILLS PARENTERALS AND OPHTHALMIC SOLUTIONS Oral Dentifrices Douche Dusting Powders Insufflations QUALITY CONTROL - Is the combination of attributes or characteristics of a product, which can be comparable to the standards that serves as the basis for measuring the uniformity of its content and determines the degree of acceptability. - Is a tool that gives the assurance that the product conforms to the standards and specifications through a system of inspection, analysis and action. - Built-in and produced, cannot be inserted into a product - Produce and deliver a safe, pure and effective product to the end user. QUALITY CONTROL • it minimizes or eliminates the risk of marketing unsafe products • reduces operating cost and losses • motivates pharmaceutical and medical professions to sell prescribe the product • guarantees conformances to regulatory requirements • guarantees product efficacy • produces higher employee morale QUALITY CONTROL - Can be interpreted by descriptive words or measurements - Quality control variation will encourage the proliferation of errors, which may be the cause of producing a defective product. - Errors may be due to 4 M’s Materials Methods Machines Men QUALITY CONTROL FORMULA RAW MATERIAL SPECIFICATION - enumerate the characteristics of all materials to be used in the product & contain only the permissible range of purity of each ingredient. -Contain a concise and precise statement of each ingredients used in the products with the correct weight and percentage. STANDARD OPERATING PROCEDURE - step by step method on the preparation & manufacturing of a product, contain all information, instructions and the acceptable established range when the product should be finished. QUALITY CONTROL FINISHED PRODUCT SPECIFICATION - cover all the characteristics that affects the performance of the product which includes purity, safety and stability. PACKAGING MATERIAL STANDARD - include all the packaging used for the product such as cans, tins, aluminum, caps, labels, cartoons, boxes, etc. TESTING METHOD - a validated and standardized procedure that yields precision and accuracy of the preparation & manufacturing of the product handled by different operators and personnel in the laboratory. QUALITY CONTROL - undesirable characteristics of a product due to its failure in conforming to the standard set of specification. - refers to a defect found in one or more product. 1. According to its MEASURABILITY a. Variable defect – can be measured directly by inspection - length, weight, height, thickness, concentration volume, viscosity, pH b. Attributive defect – can be measured by instruments - detects odor, and visual examinations like color, clarity, sheen, cleanliness, smoothness, taste and presence or absence of a characteristics. QUALITY CONTROL 2. According to SERIOUSNESS OR GRAVITY a. Critical defect – endanger life or property & may render the product non-functional. - absence of warning in label, disintegration time of an analgesic b. Major defect – affect the function of the product and render the preparation useless. - crack in the bottle, caking of an emulsion c. Minor defect – does not endanger life nor affect the function of the product. - discoloration of the label or box QUALITY CONTROL 3. According to NATURE a. Ocular defect – a visible defect - foreign particles contamination b. Internal defect – a defect that is not seen - a sub-potent drug product c. Performance defect – a defect in function - suppository that does not melt at body temperature QUALITY CONTROL Sources of Variation Materials Example a. b. c. b. c. Variation of equipment for the same process Differences adjustment of equipment Aging and improper care Methods a. b. c. Inexact procedures Inadequate processes Negligence by chance Men a. b. c. Improper working conditions Inadequate training and understanding Dishonesty, fatigue and carelessness Machines a. Variation between supplies of same substance Between batches from same supplier Within a batch QUALITY CONTROL Materials Inspection Section Analytical Laboratory Biological Testing Laboratory Specifications & Analytical Development Quality Coordinating Office QUALITY CONTROL Materials Inspection Section Analytical Laboratory Biological Testing Laboratory Specifications & Analytical Development Quality Coordinating Office QUALITY CONTROL Materials Inspection Section (are placed in area of operation, warehouse, manufacturing and packaging sections) Functions of Inspectors (Inspectors are individual who are experienced, familiar with the physical characteristics and well versed in sampling technique) • To sample & examine all raw materials received • To sample & conduct physical tests on: •All shipments of packaging materials • All manufacturing processes such as filling and packaging operations. • To maintain periodic examination on the quality of inventories throughout all phases of storage, shipping and distribution •To perform an audit which is dependent on the work done by production personnel QUALITY CONTROL Materials Inspection Section Analytical Laboratory …to be continued next meeting Prepare ½ crosswise for a short quiz Good Luck! QUALITY CONTROL http://www.animationfactory.com http://www.gifs.net/gif/index.php3?n=search.php3 http://www.bestanimations.com/