Chemistry Sample Investigation

advertisement

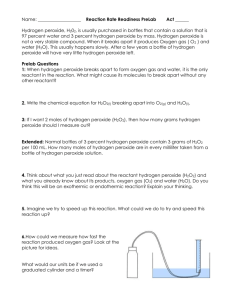

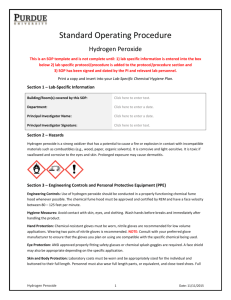

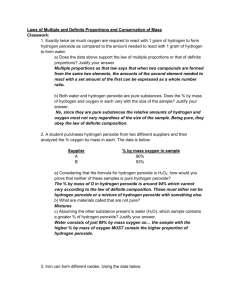

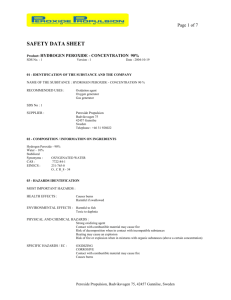

Investigate how the concentration of a hydrogen peroxide solution affects the speed at which it decomposes to produce oxygen gas Introduction Background research outlined and referenced • When I first read the investigation, I referred to the chapter on oxygen in my textbook to re-familiarise myself with the topic. • I made note of relevant facts, such as, the properties of Oxygen, and the technique used to prepare oxygen gas by decomposing hydrogen peroxide. Background research outlined and referenced • I then, referred to my brother’s Leaving Cert. Chemistry Textbook, (Declan Kennedy,Chemistry Alive) for additional information and direction on how to approach the investigation, particularly making note of ideal H2O2 concentration used. (20 volumes) • From my textbook, I also reviewed the affect the catalyst Manganese Dioxide has on the breaking down of H2O2 Background research outlined and referenced • My teacher also helped by facilitating a discussion in class and highlighting safety precautions necessary when dealing with H2O2.. I found out that it is corrosive and an oxidiser, therefore safety glasses, lab coat and vigilance are a high priority. Investigation is stated as a problem statement “ To examine that the rate at which oxygen gas is produced depends on the concentration of hydrogen peroxide used” Preparation & Planning Identification of variables • Independent variable: The concentration of hydrogen peroxide • Dependent variable: Volume of oxygen gas produced in set time, 30 sec, 60 sec. • Fixed Variables: Mass of manganese dioxide used Volume of hydrogen peroxide used Same equipment /glassware used A Fair Test • To ensure a fair test, the fixed variables must be constant. • Only the independent variable must change. • This guarantees that the rate of oxygen gas produced, depends on the concentration of hydrogen peroxide used. Resource List • Various concentrations of 20 volume hydrogen peroxide (20%, 40%, 60%, 80%, 100%) • Manganese dioxide • Water • Dropping syringe • Conical flask • Rubber bung with 2 holes for necessary tubing • Waterbath • Beehive shelf • Stop watch • Graduated cylinder for gas collection Resource List • • • • • • • Balance Waterbath Beehive shelf Stop watch Special test tubes for gas collection Safety glasses Lab coat Plan adequate to test problem statement • In order to plan the procedure fully, a trial run must be carried out. • The trial run consisted of running through the procedure to prepare oxygen gas using 100% concentration of H2O2, and then repeated at 10%. • Firstly, a stop watch was used to time how long it takes to collect 1 full test tube of oxygen gas. Plan adequate to test problem statement • The test was ran again( using each of both 100% and 10% concentrations, respectively). • This time looking at how much volume of oxygen was collected in 30 seconds • From carrying out the experiment both ways, it was decided to proceed using the latter method, i.e. monitoring the volume of oxygen gas produced in 30 seconds. Plan adequate to test problem statement • It was decided that timing would begin as soon as first oxygen bubble reached the water surface. • Each time method was carried out, it was important to ensure 1g of manganese dioxide was constant each time. ( this was in accordance to recommended mass used in textbook) Procedure Procedure listed in clear logical order • Personal Safety Equipment was put on • All reagents and apparatus was organised on bench • The standard 20 volume hydrogen peroxide solution, was labelled 100% concentration. • Further dilutions of 20%, 40%, 60%, and 80% were made up from the stock 100%. Procedure listed in clear logical order • For example, the 20% solution was made by measuring 20mls of hydrogen peroxide in a graduated cylinder and mixing it thoroughly with 80mls of water. (The other concentrations were measured using the same procedure.) Procedure for 20% concentration of hydrogen peroxide • 30 mls of hydrogen peroxide was measured and placed in the dropping syringe Procedure listed in clear logical order • 1g of manganese dioxide, weighed on a balance, was added to the conical flask. • Apparatus was set up as shown in diagram with graduated cylinder inverted in trough for collection of oxygen gas. • Hydrogen peroxide was released from dropping syringe into conical flask. Procedure listed in clear logical order • Once first gas bubble reached surface of water, stop watch was started and let run for 30 seconds. • Immediately at 30 seconds, the Volume of gas produced was easily read from graduated cylinder. Procedure listed in clear logical order • This was repeated twice for the 20 % solution, to ensure accuracy. • Procedure was repeated for 40%, 60%, 80% and 100% concentrations. Again carried three times in total. Safety • Personal Safety equipment was worn . • Care was taken when handling glassware, and in particular when handling manganese dioxide (irritant) and hydrogen dioxide (corrosive , oxidiser) Recorded Data H2O2 Concentration Volume Trial 1(ml) Volume trial 2(ml) Average Volume (ml) 20% 34ml 36ml 35ml 40% 47ml 44ml 45.5ml 60% 66ml 66ml 66ml 80% 84.5ml 85ml 84.75ml 100% 96ml 97ml 96.5ml Labelled Diagram • Graph 1.2 1 0.8 0.6 H2O2 Concentration 0.4 0.2 0 35ml 45.5ml 66ml 84.75ml 96.5ml Calculations/Data Analysis • The average results were calculated as seen in the results table. • This was then used to draw a best fit line as seen in the graph. • A wide range of concentrations from 20%100%, were tested in duplicate, which gave a confirmation of expected results. Observations • During my first practice run, I did not close the tap on the syringe after releasing the hydrogen peroxide. This could have let some of the Oxygen escape, therefore affecting results. • While using the stopwatch, I had to be alert and quick to start exactly at the first bubble, and read volume as soon as 30 seconds were over. Observations • From carrying out the procedure in repetition, I can see that the concentration of hydrogen peroxide determines the rate of oxygen produced. Comments on suitability of procedure • If more time was allowed, I feel we could have perfected our technique in both producing the oxygen and timing the rate at which it was produced. • Some factors that may have affected results: 1. When putting the hydrogen peroxide solution into the burette, the tap was often left open, spoiling that particular run and wasting the chemicals. Comments on suitability of procedure 2. Air bubbles in the graduated cylinder were a reoccuring problem, which may have altered the exact rate of oxygen being produced. Conclusion From this investigation, it can be concluded that the concentration of hydrogen peroxide greatly affects the speed at which it decomposes to produce oxygen gas.