the formulation of furosemide dispersible tablets for use in pediatrics

advertisement

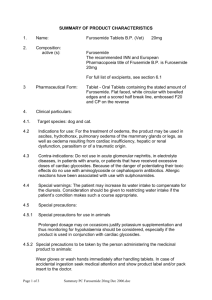

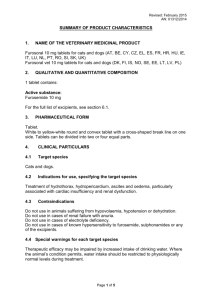

THE FORMULATION OF FUROSEMIDE DISPERSIBLE TABLETS FOR USE IN PEDIATRICS Author & supervisors Author Abwova Veronica Vugutsa B. Pharm Supervisors Prof. K. A. M Kuria Dr. P. Mbeo Background • Liquid formulations are the preferred formulation in pediatric drug administration • They Present a challenge to the formulation scientist: need for taste masking, reduced stability and bulkiness • WHO recommended the development of more pediatric friendly formulations as solid dosage forms • Most drug development companies concentrate on adult formulation • Clinical trials in pediatrics are very stringent hence most companies don’t do it Background • Furosemide is a loop diuretic used in in both pediatrics and adult for fluid overload in hypertension and heart disease • In Kenya there is no pediatric friendly formulation registered by the PPB • Patients get it extemporanously prepared or those who can afford it get it specially imported, making it quite expensive Objectives Specific objectives • To come up with a target product profile for Furosemide dispersible tablets. • To carry out pre-formulation studies on Furosemide • To carry out formulation optimization studies • To carry out tabletting of Furosemide dispersible tablets • To test the quality of the formulated Furosemide dispersible tablets Significance of the study Availability of dispersible tablets will facilitate • Accurate dosing • Convenient administration of solid dosage forms to children • Reduced bulk as opposed to liquids • Increased shelf life compared to the extemporaneously prepared formulations thus reduced trips to the pharmacy • Reduced healthcare cost Methodology-equipment • Sifter • Tabletting machine - Erweka single punch automatic tabletting machine • Weighing balance - Shimadzu • Friability tester - Erweka • Electronic tablet hardness tester – Schleuniger • Dissolution testing machine type 2 • HPLC machine – Prominence auto sampler, Sil-20AHTfrom Japan The equipment used was from the school of pharmacy departments of pharmaceutics and pharmacy practice and the department of pharmaceutical chemistry Methodology-Materials • Furosemide • Lactose • Maize starch • Sucrose • Talc • Magnesium stearate • Colloidal silicon dioxide • Sodium starch glycollate • Croscarmellose • Crospovidone The materials were obtained as gift from Laboratory and allied company Methodology • Setting up of the target product profile • Data gathering from previous preformulation studies. The molecule having been on the market for a long time, preformulation data was gathered from literature • Formulation. Granulation of the lactose was carried using starch as a binder • The granules were divided into three and a combination of two superdisintegrants added per batch : Methodology • Part of the granules were lubricated and used to produce dummy tablets • The dummies were weighed and the amount of Furosemide to be incorporated calculated • Furosemide content per tablet was determined based on its dosing in pediatrics • Tableting was then carried out and the tablets evaluated for quality using physical and analytical tests for tablets as per the USP Results • The target product profile was set as follows QUALITY ATTRIBUTE TARGET CRITICALITY 1 Dosage form Tablet 2 Potency 4mg Critical 3 Pharmacokinetics Immediate release tablet Critical 4 Appearance Elegant tablet consistent in appearance Critical 5 Identity Positive for Furosemide Critical 6 Assay 90-110% Critical 7 Weight uniformity Meets USP standards Critical 8 Content uniformity Meets USP standards Critical 9 Disintegration Not more than 3min Critical 10 Dissolution Not less than 80% released within 60minutes Critical Results • Data from previous formulation studies was obtained and summarised as below • Chemical name: 4-chloro-N-Furfuryl-5Sulphamoylanthranilic acid • Pharmacological class- Loop diuretic • Solubility: 0.0825mg/ml is the Aqueous solubility at room temperature and it increases with increase in pH • Polymorphism: 7 polymorphic forms although polymorphism has not been reported to affect bioavailability. • pKa: Furosemide has a pKa value of 3.8. It is weakly acidic. • Partition coefficient: The partition coefficient in noctanol / water reported as 2.29 Results • Formulation optimization: • Two formulations, the one with the combination of sodium starch glycollate and crospovidone as well as that of croscarmellose and crospovidone as superdisitergrants were found to give good formulations. • The formulated tablets from the two combinations were found to comply with USP specifications for tablets Results-physical tests UNIFORMITY OF WEIGHTS Formulated dispersible tablets BATCH NUMBER 1 2 3 Number of tablets 20 20 20 0.501 0.479 0.502 0.0078 0.0117 0.0075 % deviation of tablet with min weight 2.2 6.05 2.3 %deviation of tablet with max weight 3.8 4.38 3.7 Projected tablet weight (mg) 500 500 500 0.2% 4.2% 0.4% 100.2% 95.8% 100.4% Average weight (mg) STD Deviation % deviation from projected weight Calculated API content BATCH NMBER TABLET FRIABILITY BATCH NUMBER % FRIABILITY TABLET HARDNESS 1 2 3 0.98 2.6 0.9 1 2 3 Number of tablets 10 10 10 Average hardness 6.3 5.9 6.4 STD Deviation 2.2 0.639 1.3 Results-physical tests Pictures of disintegrating tablets Disintegration time(seconds) Batch 1 2 3 Average disintegration time (seconds) Standard deviation 62 137 69 4.082 14.024 10.206 Results-Analytical tests ASSAY RESULTS BATCH 1 AVERAGE %CONTENT BATCH 3 100.99 108.81 0.217 0.999 STD DEVIATION DISSOLUTION RESULTS BATCH 1 BATCH 3 AVERAGE DISSOLUTION (%) 95% 82% STD DEVIATION 15.3 13.4 Conclusion • The set target profile was achieved for two of the formulations. • The combination of sodium starch glycollate and crospovidone as well as that of croscarmellose and crospovidone can be used successfully to formulate Furosemide dispersible tablets Recommendations • Stability tests should be carried out to check for the stability over prolonged storage times and varied conditions • Flavoring can be done to improve the formulations and make it child friendly • Sweetening can also be done although this may not be necessary since the taste is not unpleasant • Thickening of the formulation can also be carried out to improve the consistency of the