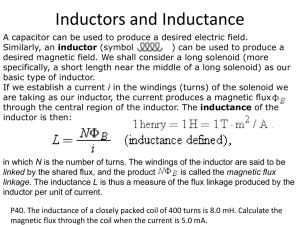

U. Kim Spiral Inductor

advertisement

Q Enhancement in Spiral Inductors Why Inductors need? Inductors Used in RFIC, MMIC Spiral Inductor Modeling Degradation of Q Q Enhancement Techniques Conclusion Microwave Devices Term Project Unha Kim (2004-21475) edmaun1@snu.ac.kr RF and Millimeter-wave Integrated Systems Lab. U. Kim 1 RF and Millimeter-wave Integrated Systems Lab. Why Inductors Need? Impedance matching DC biasing (RF choke) Phase shifting Filtering LC tank Typical Design Example A single-chip GPS Receiver CMOS technology Freq = 1.57542GHz Used more than 10 inductors About 25% of chip area U. Kim 2 RF and Millimeter-wave Integrated Systems Lab. Inductors Used in RFIC, MMIC Inductors Ribbon Inductor Loop Inductor Meandered Inductor Spiral Inductor Bondwire Inductor Active Inductor Considerations Inductance Quality Factor Self Resonant Frequency U. Kim 3 RF and Millimeter-wave Integrated Systems Lab. Some Types of Inductors Ribbon inductor Less than 1nH High Z0 needed Relatively ‘pure’ inductance (low parastics) Often used in distributed amplifiers Loop inductor Used extensively in the early days of MMICs Inefficient use of chip area Recently, it is used very little Meandered track inductor Can get more than 1nH Lmeandered < Lstraight track with same length U. Kim 4 RF and Millimeter-wave Integrated Systems Lab. Some Types of Inductors Bondwire inductor Diameter = 1mil (0.001 inches) More surface area per length than spirals Less resistive loss, Higher Q L = 1nH / mm Active inductor Higher noise Power consumption Limited linearity - Distortion L = C / (gm1gm2) Discrete inductor L = 2 ~ 100nH with 2 ~10% tolerance Q = 50 to 200 (1 to 2GHz) SRF = 4 to 10GHz U. Kim 5 RF and Millimeter-wave Integrated Systems Lab. Spiral Inductor The most frequently used High inductance per unit area Square, octagon, circular type Qcircular > Qoctagon > Qsquare Air bridge crossover or dielectric spaced underpass Din : Inner dimension Dout : Outer dimension S : Spacing W : Width t : Thickness n : Number of turns U. Kim 6 RF and Millimeter-wave Integrated Systems Lab. Spiral Inductor Modeling Ls : Mutual Couplings C.Patrick Yue, “Physical Modeling of Spiral Inductors on Silicon” Rs : DC & AC resistance (skin effect) Cs : Series Capacitance Cox : Oxide Capacitance Csi : Si Substrate Capacitance Rsi : Si Substrate Ohmic Loss U. Kim 7 RF and Millimeter-wave Integrated Systems Lab. Degradation of Q Problems Limitation on the number of turns Occupies large area Series (DC + AC) resistance Substrate loss Some Proposed solutions Patterned ground shield Differentially driven inductor Copper metallization Three dimensional inductor U. Kim 8 RF and Millimeter-wave Integrated Systems Lab. Dominant Effects on Spiral Inductor SRF Rs, Cs effect dominant Csi , Rsi effect dominant Low frequency : series resistance effect High frequency : substrate loss effect Conductive Si substrate have a defect! How can we reduce the substrate loss? U. Kim 9 RF and Millimeter-wave Integrated Systems Lab. Other Dimensional Effects on Spiral Inductor 1 2 3 1. Size dependency larger size, larger substrate loss 2. Oxide thickness dependency thicker oxide, lower substrate loss 3. Metal thickness dependency thicker metal, lower Rs Or, using Cu instead of Al, lower Rs U. Kim 10 RF and Millimeter-wave Integrated Systems Lab. Solid Ground Shield Severe substrate loss at high freq. Si substrate is vulnerable Usually ρ < 20Ω·cm GaAs substrate is less vulnerable Semi-Insulating Substrate SGS To reduce substrate loss Conductive ground shield between oxide and substrate Metal or polysilicon deposition Eddy current ☞ L↓ Q↓ Capacitance increases ☞ SRF↓ U. Kim 11 RF and Millimeter-wave Integrated Systems Lab. Eddy Current Eddy current occurs when a conductor is subjected to time-varying-magnetic field and is governed by Faraday’s law. Eddy currents produce their own magnetic fields to oppose the original field Eddy currents reduce the net current flow in the conductor Increase the ac resistance U. Kim 12 RF and Millimeter-wave Integrated Systems Lab. Patterned Ground Shield PGS Orthogonal to spiral (block eddy current) Avoid attenuation of the magnetic field C.Patrick Yue, “On-Chip Spiral Inductors with Patterned Ground Shields for Si-Based RFICs” Isolates between inductor and ground termination of the electric field Aluminum metal or polysilicon (better) Capacitance increases ☞ SRF↓ U. Kim 13 RF and Millimeter-wave Integrated Systems Lab. Patterned Ground Shield (cont’) Q factor up to 33% SRF decrease SRF U. Kim 14 RF and Millimeter-wave Integrated Systems Lab. Patterned Ground Shield (cont’) 2 1 1. Parallel LC resonator at 2GHz There are many advantages in designing oscillator. 2. Reduce the substrate coupling b/w two adjacent inductors by 25dB Using PGS has both advantages and disadvantages. U. Kim 15 RF and Millimeter-wave Integrated Systems Lab. Differentially Driven Inductors Differential circuits have robustness and superior noise rejection properties Can get greater Q without altering the fabrication process Differential signal path requires extra chip area compared to a single-ended Symmetrical inductor has better performance than asymmetric inductor. Adjacent conducting strips : voltage (anti-phase), current (same direction) Reinforces the magnetic field by the parallel groups of conductors Increases the overall inductance per unit area High V difference Same I direction Low V difference Same I direction asymmetric U. Kim symmetric 16 RF and Millimeter-wave Integrated Systems Lab. Differentially Driven Inductors (cont’) Lseries. Spiral inductor modeling Lsub.s Lseries.d s Single-ended Lsub.d Lseries.d and Lseries.s are similar low-freq. dominant factor Lsub.d is less than L sub.s up to 2 times high-freq. dominant factor Low freq. performance is similar (c) is superior at high freq. Differential excitations Mina Danesh, “Differentially Driven Symmetric Microstrip Inductors” U. Kim 17 RF and Millimeter-wave Integrated Systems Lab. Differentially Driven Inductors (cont’) common node Less affected by substrate parastics 50% grater Q factor than single-ended Broader range of operating frequencies U. Kim 18 RF and Millimeter-wave Integrated Systems Lab. Circular Shaped Inductors 1GHz S. Chaki, “Experimental Study on Spiral Inductors” Rcircular and Roctaogonal is smaller by 10% than Rsquare Decreasing conductor spacing is better than increasing conductor width CIW ↑ U. Kim Cox, C si ↑ 19 RF and Millimeter-wave Integrated Systems Lab. Reducing Line Resistance AC resistance ☞ W, t > 2δs DC resistance The four best conducting metal resistivities are Silver : 1.62 μΩ·cm Copper : 1.72 μΩ·cm Gold : 2.44 μΩ·cm Aluminum : 2.62 μΩ·cm If we use Cu instead of Al, Rs would be reduced significantly Some paper proposed that ( 3um-thick Al ) = ( 1um-thick Cu ) But thicker metal, larger CIW Damascene Cu metallization Cu metallization is not mature in RFIC & MMIC U. Kim 20 RF and Millimeter-wave Integrated Systems Lab. Cu Damascene Interconnects (a) Etch trenches and via holes (d) CMP Cu and Ta, CVD nitride Example : Cu metallization in VLSI technology Better conductor than aluminum Higher speed and less power consumption (b) Ta barrier layer and Cu seed layer Higher electomigration resistance Diffusing freely in silicon and silicon dioxide, causing heavy metal contamination, need diffusion barrier layer Hard to dry etch, no simple gaseous chemical compounds (c) Electrochemical plating Cu U. Kim 21 RF and Millimeter-wave Integrated Systems Lab. High Q Inductor in Single Damascene Al sheet resistance : 20~100 Q factors up to 24 at 2.8nH by using think metal layer Non-effective unless the substrate losses are lowered sufficiently Snezana Jenei, “High Q Inductor Add-on Module in Thick Cu/SiLKTM single damascnene” U. Kim 22 RF and Millimeter-wave Integrated Systems Lab. Conclusion Inductors are needed in RFICs & MMICs High Q inductors are required for high performance Spiral inductors are mostly used The Q of spiral inductor is very low Substrate loss and series resistance are major effects on Q Some Q-enhancement techniques are suggested PGS + Cu-metal + Octagonal shaped inductor is best performance It will be trade-off relation between high-Q process and cost U. Kim 23 RF and Millimeter-wave Integrated Systems Lab. References C. Patrick Yue, “Physical Modeling of Spiral Inductors on Silicon” Mina Danesh, “Differentially Driven Symmetric Microstrip Inductors” C. Patrick Yue, “On-Chip Spiral Inductors for Silicon-Based RFICs” Snezana Jenei, “High Q Inductor Add-on Module in Thick Cu/SiLK single damascene” Daniel C. Edelstein, “Spiral and Solenoidal Inductor Structures on Silicon Using Cu-Damascene Interconnects” Joachim N. Burghartz, “On the Design of RF Spiral Inductors on Silicon” S. Chaki, “Experimental Study on Spiral Inductors” C. Patrick Yue, “On-Chip Spiral Inductors with Patterned Ground Shields for Si-Based RFICs” John Rogers, “Radio Frequency Integrated Circuit Degisn”, Artech House Thomas H. Lee, “The Design of CMOS RFICs”, Cambridge Univ. press I. D. Robertson, “MMIC Design”, IEE press U. Kim 24 RF and Millimeter-wave Integrated Systems Lab.