14.Cell and Enzyme Immobilization.web

advertisement

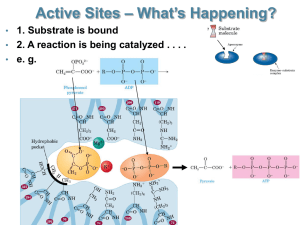

Cell and Enzyme Immobilization Cells and enzymes as biocatalysts enzyme S P cells cell based versus enzymatic processes glucose glucose/fructose glucose isomerase glucose ethanol multi-enzymes acting sequentially • whole cells preferred when multi-step • enzymes preferred for 1 or 2 step transformations • competing side reactions with whole cells • sterility problems • cell lysis • other physiological requirements (nutrients, O2) Advantages to immobilizing enzymes and cells • increased stability,weeks or months • stable to heat, pH extremes, storage, reaction • facilitates recovery for repeated or continuous use (essential for soluble enzymes) • cellular activity is enzymatic activity (biotransformations) Immobilization Techniques bound entrapped matrix encapsulation adsorbed microencapsulation covalently attached support enzyme or cell Matrix or lattice entrapment in polymeric gels • monomer, crosslinker, polymerization catalyst, cells or enzyme • forms lattice structure, entrapping cells/enzyme • eg. polyacrylamide cross-linked with N,N'-methylenebisacrylamide (covalent gel) Alginate and carrageenan non-covalent gels • Naturally derived polymers extracted from seaweed • Used in food industry as a thickener – ice cream, pudding, frozen drink concentrates, jam, yoghurt, bakery products, confectionery • Dental molds • Immobilization technology as an encapsulating matrix • Natural polymers are highly variable in composition and their chemistry is generally not known • Composition affects properties Alginate a-L-mannuronic acid b-D-guluronic acid Alginate polymer Alginate block structures (Mikkelsen and Elgsaeter, 1995; Smidsrod and Skjak-Braek, 1990) Alginate Matrix Binding of Ca2+ to G Eggbox model for Ca2+ binding Structure of the Alginate-Ca2+ Matrix Cell entrapment protocol - external gelation M Ca++ Dropwise addition of alginate/cells into CaCl2 gelation bath DNA entrapment protocol - emulsification/internal gelation Ca++ M alginate droplet containing DNA, microcrystalline CaCO3 alginate in oil emulsion 6.5 7.5 CaCO3 M M oil recycle canola oil: 40oC KCl M carrageenan: 40oC 5oC static mixer M separator settler yeast 40oC static mixer carrageenan beads to bioreactor Immobilized yeast technology Kenics static mixer to encapsulate brewing yeast Continuous brewing gas out beer out bead disengagement section draft tube temperature control jacket medium in sparger - air in Labatt continuous airlift reactor Tannase from Aspergillus oryzae to hydrolyze tea tannins • tannins represent 25% of extractables in tea leaves • cause creaming (turbidity) on cooling • desire tea to be clear and bright • tannase controlled hydrolysis of tannins, retaining flavour • encapsulated tannase remained stable for 1 month • 3 successive batch cycles during 48 h processing Membrane coating polyanion core (alginate) polycation membrane • chitosan • poly-L-lysine • co-guanidine DNA microspheres following GI transit Damon/Connaught process to encapsulate pancreatic islets coated with poly-L-lysine islets in alginate bead liquify alginate core with citrate or EDTA Microencapsulation • spherical ultrathin semipermeable membrane enclosing cell/enzyme suspension/solution • interfacial polymerization reaction (nylon) NH2(CH2)6NH2 + ClCO(CH2)8COCl NH2(CH2)6NH-CO(CH2)8CONH(CH2)6NH-CO(CH2)8COnylon 6-10 polyamide + HCl Microencapsulation protocol - interfacial polymerization oil soluble cross-linker M chitosan cells/chitosan in oil emulsion Encapsulation of lobster carotenoids as natural food pigment Adsorption • simple adsorption of cell/enzyme onto support (carrier) with adsorptive properties – anion exchange resins (DEAE cellulose, Sephadex) – cation exchange resins (carboxymethylcellulose) Covalent binding to support • common technique • carriers – natural materials (cellulose, active carbon) – inorganic materials (glass, stainless steel, ceramics (porous), silica (sand) – enzymes/cells have reactive groups (NH2, OH, SH, COOH) – carriers are usually unreactive so activation step required Corning glass process (glucose isomerase and lactase) 1. support activation ceramic + (C2H5O)3Si(CH2)3NH2 ceramic-Si-(C2H5O)2(CH2)3NH2 (3-aminopropyltriethoxysilane) (activated support) 2. cross-linking of cells/enzyme cells-NH2 + OHC-(CH2)3-CHO (glutaraldehyde) cell-N=CH(CH2)3CH=N-carrier + H2O Cross-linking intramolecular or cell to cell • enzyme or cell cross-linked to – another enzyme molecule – another protein (BSA) – insoluble carrier molecule • glutaraldehyde cross-links NH2 groups • hexamethylene diamine links COOH groups Comparison of immobilization techniques • adsorption and gel entrapment – simple, gentle and efficient – enzyme/cells often released (leaky); solved by cross-linking – gas buildup may be problem • microencapsulation – – – size exclusion (eg. antibodies) only small substrates can be used may lead to inactivation • covalent attachment and cross-linking – strong attachment – laborious and expensive – often leads to significant inactivation Reaction kinetics or mass transfer control • diffusional resistances minimized by – decreasing particle size (increase surface area/volume ratio) – increasing [R]bulk – improved mixing, agitation – increasing porosity – optimizing distribution of enzyme/cells boundary film Rbulk Vmax [R] v K m [R] CH3CHOHCOOH + O2 CH3COOH + CO2 + H2O L-lactate-oxygen 2-oxidoreductase