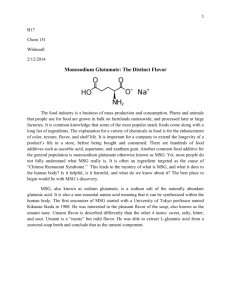

Industrial Product From Microbial Process

advertisement

MIC 303 INDUSTRIAL AND ENVIRONMENTAL MICROBIOLOGY INDUSTRIAL PRODUCTS FROM MICROBIAL PROCESSES (CON’T) Vinegar an alcoholic liquid that has been allowed to sour. “Vinegar” = the French word “vin” (wine), “aigre” (sour). It is primarily used to flavor and preserve foods and as an ingredient in salad dressings and marinades. also used as a cleaning agent. Two way of production: i. the microbial fermentation of alcohol ii. by the dilution of acetic acid Key equation: CH3CH2OH + O2 → CH3CO2H + H2O Types of vinegar Malt vinegar Wine vinegar Other vinegars Cider vinegar Rice vinegar Rice vinegar Spirit vinegar Chemical synthesis of vinegar Balsamic vinegar Balsamic vinegar Microbes used Key organism: Acetobacter (formerly known as Mycoderma), pertinent strains: Acetobacter aceti, Acetobacter pastorianus and Acetobacter hansenii Acetobacters are microscopic bacteria that live on oxygen bubbles. Whereas the fermentation of grapes or hops to make wine or beer occurs in the absence of oxygen, the process of making vinegars relies on its presence. Conversion of ethanol to acetic acid is accompanied by secondary fermentation resulting in generation of aroma-active compounds (acetaldehyde, ethyl acetate and other esters and higher alcohols such as methyl butanol) Raw materials Flavour: depends on the source of the alcohol. Base materials: Herbs and fruit used to flavor vinegar. Commonly used herbs include tarragon, garlic, and basil. Popular fruits include raspberries, cherries, and lemons. Acetozym In the vinegar factory, this process is induced by feeding acetozym nutrients into the tanks of alcohol. Acetozym nutrients are manmade mother of vinegar in a powdered form. It is a natural carbohydrate called cellulose. This film holds the highest concentration of acetobacters. It is skimmed off the top and added to subsequent batches of alcohol to speed the formation of vinegar. The Manufacturing Process The Generator Method modern commercial production of vinegar. submerged fermentation method. These methods are based on the goal of infusing as much oxygen as possible into the alcohol product. The Manufacturing Process The Submerged Fermentation Method commonly used in the production of wine vinegars. Production plants are filled with large stainless steel tanks called acetators. The acetators are fitted with centrifugal pumps in the bottom that pump air bubbles into the tank in much the same way that an aquarium pump does. As the pump stirs the alcohol, acetozym nutrients are piped into the tank. The nutrients spur the growth of acetobacters on the oxygen bubbles. A heater in the tank keeps the temperature between 80 and 100°F (26-38°C). The Manufacturing Process The Orleans Method Slow process. manufacture of highquality vinegars. also called continuous method. The Manufacturing Process Natural Fermentation Made easily by fermenting fresh sap into plastic or earthen jar until it becomes sour. Then pack into plastic bottles and place under the heat of sun for few days. PRODUCTION OF ANTIBIOTICS PENICILLIN Antibiotics produced by Microorganisms Antibiotic Cephalosporin Chloramphenicol Erythromycin Griseofulvin Penicillin Streptomycin Tetracycline Gentamicin Producing microorganism Cephalosporium acrimonium Streptomyces venezuelae Streptomyces erythreus Penicillium griseofulvin Penicillium chrysogenum Streptomyces griseus Streptomyces aureofaciens Micromonospora purpurea Synthesis Pathway -ketoglutarate + AcCoA → homocitrate → L-αaminoadipic acid → L-Lysine + β-lactam The term "penam" is used to describe the core skeleton of a member of a penicillin antibiotic. This skeleton has the molecular formula R-C9H11N2O4S, where R is a variable side chain. Moa of Penicillin First antibiotic to have been manufacture in bulk All penicillin like antibiotics: inhibit synthesis of peptidoglycan, an essential part of the cell wall. do not interfere with the synthesis of other intracellular components. do not affect human cells because human cells do not have cell walls. Spectrum of Activity used in the treatment of bacterial infections caused by susceptible, usually Gram-positive, organisms. effective against many previously serious diseases such as syphillis and Staphylococcus infections. Some members (e.g. amoxicillin) are also effective against Gram negative bacteria but not Pseudomonas aeruginosa. Moa of Penicillin The β-lactam moiety (functional group) of penicillin binds to the DD-transpeptidase (links the peptidoglycan molecules in bacteria) → weakens the cell wall of the bacterium, causes cytolysis or death due to osmotic pressure. In addition, the build-up of peptidoglycan precursors triggers the activation of bacterial cell wall hydrolases and autolysins, which further digest the bacteria's existing peptidoglycan. Gram-positive bacteria are called protoplasts when they lose their cell wall. Gram-negative bacteria do not lose their cell wall completely and are called spheroplasts after treatment with penicillin. Production of Penicillin Penicillin was the first important commercial product produced by an aerobic, submerged fermentation and using a fedbatch culture technique. Used as input material for some semi synthetic antibiotics. Secondary metabolite, produced only in the stationary phase when growth of the fungus is inhibited by stress, not produced during active growth. PRODUCTION OF MONOSODIUM GLUTAMATE Monosodium Glutamate (MSG) MSG has first isolated as glutamic acid in 1866 by German chemist (Ritthausen) through the acidic hydrolysis of gliadin, a component of wheat gluten. In 1908, Kikunae Ikeda, a Japanese chemist patented a process for isolating MSG from wheat flour and produced commercially under trade name “Ajinomoto” (the origin of flavour). The Manufacturing Process Preparation and Repulping Processess of Raw Materials Natural crops is used as raw materials (easily obtained). Ex: Tapioca and sago or sugarcane (molasses). Tapioca and sago powder are mixed with water to form starch slurry. Liquefaction and Saccharification Process Starch sluury is converted into glucose solution through enzymatic action. Sterilization Process The medium will sterilized using steam sterilization to eliminate contaminants. The Manufacturing Process (cont) Fermentation Process The heat sterilized raw materials and other nutrients are put into fermenter. Microbes are added to convert glucose into glutamic acid. Crystallization Process Acidifying of fermentation materials are carried out to crystallized the glutamic acid produced. The glutamic acid crystal cake are separated from acidified fermentation broth. Conversion of Glutamic acid to MSG By adding glutamic acid cake into NaOH solution (food grade) to convert glutamic acid into MSG. The Manufacturing Process (cont) Cleaning of MSG The impurities are removed by using active carbon to form more clean and clear MSG. Active carbon: many micro holes to attach impurities on its surface. Crystallization of MSG Clean MSG solution is concentrated by heating. The crystal of MSG will be formed. Drying of MSG The crystal then are vibrated and transported through hot air in closed system until dry. The Manufacturing Process (cont) Sieving Process Seggregating process to separate MSG crystall accordance to required size. Packaging MSG Production Process Starch (Tapioca Flour, Maize Flour, Sago Flour) + H2O Starch slurry Liquefaction (85ºC cooled) Enzyme saccharification (60 hr, 5560ºC) Glucose syrup and nutrient addition (ex Yeast Extract) Preculture of Brevibacterium lactofermentum cells Substrate sterilization (121 ºC) Inoculation Batch Fermentation (1-2 weeks) Filtration (harvest) Ion Exchangers (to remove excess mineral salt) Acidification (pH 2.2 IEP) Cooling + Crystallization (40 days, 14 ºC) Glutamate acid slurry Separation Crude MSG (Magenta colour) Decolorization (Activated carbon, pH 6.4) Filtration + NaOH Pure MSG (pH 6.9, 50% MSG) Final Filtration Crystallization Separation Sedimentation Drying Packing INDUSTRIAL ALCOHOL FROM WASTES (OVERVIEW) INDUSTRIAL ETHANOL Industrial Production of Ethanol (Bio Oil Process) Concentrated sugar cane molasses + mineral (Substrate preparation) Concentrated yeast stream (Pichina stipitis, S.cerevisiae, Candida schatae) Production fermenter (anaerobic) Batch Fermentation (7 days) Centrifugation/ Filtration Ethanol vapourizer Concentrated ethanol vapour Heat exchange Cooler Collection tank Bottling