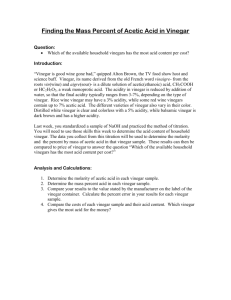

Rota Community Kitchen

advertisement

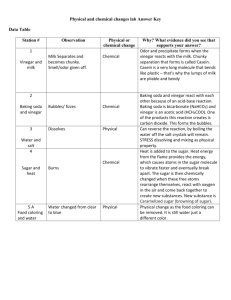

Jang H. Kim, Ph. D. Northern Marianas College Cooperative Research, Extension, and Education Service After harvested, the quality of produce is deteriorated in proportional to the storage period Tropical produce are highly perishable and the shelf-life is comparatively short Good post-harvest practice and strategy for maintaining the quality of local produce OR…. Add more value by transforming fresh produce to processed food product Utilize local produce to process jams, juices, pickles, wines, oils, chips and so Provide good opportunities to access potential niche markets Export the value-added product and contribute to local economy Facility to provide opportunity for people to use various processing equipment to develop their own value-added product Financed by pooled entrepreneur, loans and grants from private, and government sources Users pay into a kitchen-operating fund in amounts much lower than their own operation cost This subsidy reduces risk in starting businesses As a business grows within a community kitchen, it may need to move out, either because of the limited facility capacity or management policy (Business Incubation) Usually have operating boards and bylaw governing the operating procedures The community must be willing to provide continuous support for the effort over the long term The kitchen must be operated as a business rather than as a hobby Food Safety must be the kitchen user’s top priority There must be an ongoing commitment to worker and visitor safety The management of the kitchen must have: - Business licenses, certificates, and other permits - Insurance - Valid tuberculosis test - Occupancy certification The users or clients must have: - Business licenses - Insurance - Valid tuberculosis test FDA guidelines on current Good Manufacturing Practice in manufacturing, packaging, or holding human food (http://www.access.gpo. gov/nara/cfr/waisidx_99/21cfr110_99.html ) Operation Handbook based on HACCP (http://www.nal.usda.gov/fnic/foodborne/haccp /index.shtml) Utilization of local produce - Sour sop - Calamansi lemon - Coconut - Sweet potato Unique products to create niche markets for drinking vinegar, sweet potato wine, . . . Fruits and Vegetables a. Wet process - Juice, wine, jam, ice cream - and VINEGAR b. Dry process - Confectionary, chocolate - Dried fruits - Powder - Bakery (cookies and breads) Vinegar??? Vinegar!!! One of the most popular healthy drinks in Korea and Japan Highly profitable Throw one stone kill 3 birds! - Juice Wine Vinegar Wine is our target product, but… The equipment can be used for other value-added products Priority Equipment - Hot water bath for pasteurization or blanch - High pressure cooker or processor - Juice extraction machine (wet) - Filtration system (membrane) - Bottling machine (filler and capper) - Steam or heating kettle General Equipment - Refrigerator - Freezer - Washing sinks - Packaging machine NMC-CREES Food Safety program will allot some portion of its HATCH fund for Rota Community Kitchen for 3 years (as a seed grant) - 100K excluding personnel, R&D cost Basic equipment for vinegar processing - Machine capacity and price range study needed Facility renovation not allowed • Reinvest profits for community kitchen • Additional processes • Contribute to local economy • New Product Development • Value-added Process • Technical Assistance • Processing equipment • Food processing rules and regulation information