lecture 1Fiber fabrication

advertisement

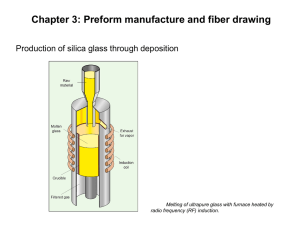

FIBER FABRICATION Two basic techniques in fabrication of all glass optical waveguides. - Vapor-phase oxidation process - Direct melt methods Direct Melt Methods -Optical fibers are made directly from the molten state of purified components of silica glasses. Vapor –phase Oxidation Process -Highly pure vapors of metal halides react with O2 to form white powder of SiO2 particles. -The particles are then collected on the surface of a bulk glass and are sintered to form a glass rod. -This rod or tube is called a preform. -Typically 10-25mm dia and 60-120cm long. -Fibers are made from preform using the following equipment Outside Vapor –phase oxidation -Loss less than 20dB/km -A layer of SiO2 particles called SOOT is deposited from a burner onto a rotating graphite. -The glass SOOT adheres to this bait rod and layer and layer, a cylindrical porous glass preform is build up. -By controlling the constituents of the metal halide vapor stream during the deposition process, the glass dimensions desired for the core and cladding can be incorporated into the preform. -When the deposition process is completed the mandral is removed and porous tube is then virtified in a dry atmosphere at high temperature to a clear glass preform. - This preform is mounted in a fiber drawing tower and made into a fiber. Vapor-phase Axial Deposition - SiO2 particles are formed in the same way. -These particles emerge from the torches they are deposited onto the end surface of a silica glass rod which acts as a seed. -A porous preform is grown in the axial direction by moving the rod upward. -The rod is also continuously rotated to maintain cylindrical symmetry of the particle deposition. -As the porous preform moves upward, it is transformed into a solid, transparent rod preform by melting with the carbon ring heater. Modified Chemical Vapor Deposition -Pioneered at Bell laboratories -Low loss graded index fibers -The glass vapor particles , arising from the reaction of metal halide gases and oxygen flow through inside of silica tube. -As the SiO2 are deposited, they are sintered to clear glass layer which travel back and forth along the tube. -When the desired thickness of glass rod have been deposited, the vapor flow is shut off and tube is heated strongly to cause it to collapse into solid rod preform. -The fiber is drawn from this preform rod , core consists of vapor deposited material and cladding consists of original silica tube. Plasma Activated Chemical Vapor Deposition: -Philips research invented -Similar to MCVP - A non isothermal microwave plasma operating at low pressure initiates the chemical reaction. -With the silica tube , a moving microwave resonator operating at 2.45GHz generates a plasma inside the tube to activate the chemical reaction. -This process deposits clear glass material directly on the tube wall. -No SOOT formation , no sintering is required. -When desired glass thickness is deposited , the tube is collapsed into a preform. Double Crucible Method: -Silica, Chalgenide and halide glass fibers can be made. -Glass rods for the core and cladding materials are first made separately by melting mixtures of purified powders. - These rods are used as feedstock for each of two concentric crucibles. -The inner crucible contains the molten core glass and outer contains cladding glass. -The fibers are drawn from the molten state through orifices in the bottom of the two concentric crucibles in a continuous production process. -Attention must be paid to avoid contaminants arise from furnace environment and from the crucible. MECHANICAL PROPERTIES OF OPTICAL FIBER Fiber strength and durability -Optical fibers exclusively fabricated from silica or compound of glass. -Materials are brittle and exhibit perfect elasticity until their breaking point is reached. - Bulk material strength of flawless glass is quite high and estimated for individual materials using the relationship St= (עpE/4la)1/2 St= theoritical cohesive strength עp= Surface energy of the material E= Youngs modulus of the material la=atomic space/bond distance -Bulk material strength reduced by the presence of surface flaws within the material. -In order to treat surface flaws in glass, the griffith theory is normally used. -This theory assumes that surface flaws are narrow cracks with small radii of curvature at their tips. -It postulates that the stress is concentrated at the tip of the crack which leads to crack growth. -Stress intensity factor Ki=SYC1/2__________1 S= macroscopic stress on the fiber Y= constant C= depth of the crack -Critical stress intensity factor where fracture occurs Kic=(2Eעp)1/2______________2 -Combining 1 and 2 S= [2Eעp/Y2C]1/2 -A primary protective coating is usually applied , mechanically induced flaws can be minimized. - Flaws also occur due to chemical and structural changes. -Another effect is stress corrosion, occurs bec of molecular bonds are attacked by water