LiCoO2-presentation-LB - Department of Chemical Engineering

advertisement

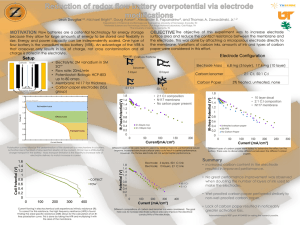

Capacity Fade Studies of LiCoO2 Based Li-ion Cells Cycled at Different Temperatures Bala S. Haran, P.Ramadass, Ralph E. White and Branko N. Popov Center for Electrochemical Engineering Department of Chemical Engineering, University of South Carolina Columbia, SC 29208 Objectives Study the change in capacity of commercially available Sony 18650 Cells cycled at different temperatures. Perform rate capability studies on cells cycled to different charge-discharge cycles. Perform half-cell studies to analyze causes for capacity fade. Use impedance spectroscopy to analyze the change in cathode and anode resistance with SOC. Study structural and phase changes at both electrodes using XRD. Characteristics of a Sony 18650 Li-ion cell Cathode (positive electrode) - LiCoO2. Anode (negative electrode) - MCMB. Cell capacity – 1.8 Ah Characteristics of a Sony 18650 Li-ion cell Characteristics Mass of the electrode material (g) Geometric area (both sides) (cm2) Loading on one side (mg/cm2) Total Thickness of the Electrode (m) Specific Capacity (mAh/g) Positive LiCoO2 Negative Carbon 15.1 7.1 531 603 28.4 11.9 183 193 148 306 Experimental – Cycling Studies Cells cycled using Constant Current-Constant Potential (CC-CV) protocol. Cells were discharged at a constant current of 1 A. Batteries were cycled at 3 different temperatures – 25oC, 45oC and 55oC. Experiments done on three cells for each temperature. Rate capability studies done after 150, 300 and 800 cycles - Cells charged at 1 A and discharged at currents of 0.2, 0.4, 0.6, 0.8 and 1.0 A. Experimental - Characterization Batteries were cut open in a glove box after 150, 300 and 800 cycles. Cylindrical disk electrodes (1.2 cm dia) were punched from both the electrodes. Electrochemical characterization studies were done using a three electrode setup. Impedance analysis - 100 kHz ~ 1 mHz ±5 mV. Material characterization - XRD studies and SEM, EPMA analysis. Experimental - Characterization LiCoO2 or carbon inert material porous electrode separator Lithium Foil reference electrode -lithium foil current collector Swagelok TM Three Electrode Cell Discharge Curve Comparison of Sony 18650 Cells after 800 Cycles 4.20 300-55 300-45 300-RT Voltage (V) 3.76 3.32 Fresh 2.88 800-45 2.44 2.00 0.0 490-55 0.4 800-RT 0.8 1.2 Capacity (Ah) 1.6 2.0 Capacity Fade as a Function of Cycle Life Percentage Capacity Fade Temperature RT 45 55 50 100 150 300 500 800 3.8 5.11 6.09 10.29 22.5 30.63 3.8 5.46 7 11.75 26.46 36.21 4.3 6.4 9.4 27 70.56 fail Capacity Fade as a Function of Cycle Life 1.90 Capacity (Ah) 1.55 RT 1.20 45oC 0.85 55oC 0.50 0 100 200 300 400 500 Cycle Number 600 700 800 Charge Curves at Various Cycles 300 1.1 Current (A) 0.5 0.1 0.1 Room Temperature 2 3 0 4 1 50 Time (h) 300 0.9 150 1 0.7 0.5 0.3 0.1 55 deg C 0 2 Time (h) 45 degree-charge RT-charge 1 0.5 0.3 1 300 800 0.7 0.3 0 150 50 0.9 1 0.7 Current (A) Current (A) 150 50 800 0.9 1.1 1 2 T ime (h) 3 3 45 deg C Change in Charging Times with Cycling 1 1 1.5 1 CC Time (h) 150 150 1.0 150 300 300 800 300 800 0.5 490 3 300 800 RT Constant Current 45 55 CV Time (h) 0.0 150 2 300 800 1 300 150 150 1 1 1 0 RT Constant Voltage 45 55 Rate Capability after 150 and 800 Cycles Discharge Capacity (Ah) 2.00 Fresh 1.75 150-RT 1.50 150-45 150-55 800-45 800-RT 1.25 1.00 0.0 0.2 0.4 0.6 0.8 1.0 1.2 Applied Current (A) Rate Capability comparison after 150 and 800 cycles Nyquist Plots of Sony Cell at RT and 55oC 0.10 ZIm ()-Fresh 0.08 300-RT -0 SOC 300-55-0 SOC Fresh-RT -0 SOC Fresh-55-0 SOC 0.06 0.04 0.02 0.00 0.30 0.35 0.40 ZRe( ) 0.45 0.50 Nyquist Plots of Sony Cell at RT and 45oC 0.20 0.4 800-RT-0 SOC 800-45-0 SOC Fresh-RT-0 SOC Fresh-45-0 SOC 0.3 0.12 0.2 0.08 0.1 0.04 0.00 0.3 0.4 0.5 0.6 ZRe () 0.7 0.0 0.8 ZIm()-800 cyc ZIm()-Fresh 0.16 Negative Electrode Resistance (Fully Lithiated) Resistance (cm2 ) 600 RT 45 Deg C 55 Deg C 500 400 300 200 100 0 60 120 180 Cycle Number 240 300 Positive Electrode Resistance (Fully Lithiated) Resistance (cm2 ) 500 RT 45 Deg C 55 Deg C 400 300 200 100 0 0 60 120 180 Cycle Number 240 300 Comparison of Electrode Resistances 200 Carbon 150 100 50 600 0 RT 150 Cycles 45 500 55 Resistance (ohm-cm 2 ) Resistance (ohm-cm 2 ) LiCoO2 400 300 LiCoO2 Carbon 200 100 0 RT 45 55 300 Cycles Possible Reasons for Rapid Capacity Fade at Elevated Temperatures The SEI layer formed on a graphite electrode changes in both morphology and chemical composition during cycling at elevated temperature. The R-OCO2Li phase is not stable on the surface and decomposes readily when cycled at elevated temperatures (55oC). This creates a more porous SEI layer and also partially exposes the graphite surface, causing loss of charge on continued cycling. The LiF content on the surface increases with increasing storage temperature mainly due to decomposition of the electrolyte salt. SEI and electrolyte (both solvents and salt) decomposition have a more significant influence than redox reactions on the electrochemical performance of graphite electrodes at elevated temperatures. Nyquist Plot of Fresh LiCoO2 as a function of SOC at RT 250 Zim (ohm) 200 150 100 0 SOC 50 SOC 100 SOC 50 0 0 100 200 300 Zre (ohm) 400 500 600 Nyquist Plot of Fully Delithiated LiCoO2 as a function of Storage Time at RT Day 1 Day 3 Day 5 Day 7 Day 9 140 ZIm (ohms) 120 100 80 60 40 20 0 0 50 100 150 200 250 ZRe (ohms) 300 350 400 Nyquist Plot of Fully Lithiated LiCoO2 as a function of Storage Time at RT 250 Day Day Day Day ZIm (ohms) 200 1 2 3 4 150 100 50 0 0 100 200 300 400 ZRe (ohms) 500 600 700 800 Specific Capacity of Positive and Negative Electrodes at Various Cycles and Temperature Cell (Cycle No. – Temperature) Fresh Specific capacity (mAh/g) LiCoO2 Carbon 147.81 306.17 150-RT 144.29 2.38% 299.55 2.16% 150-45 143.12 3.17% 296.58 3.13% 150-55 141.25 4.44% 290.56 5.10% 300-RT 139.17 5.84% 283.95 7.26% 300-45 138.21 6.49% 282.17 7.84% 300-55 125.10 15.36% 246.58 19.46% Comparison of Capacity Fade of Individual Electrodes with Full Cell Loss Cell (Cycle No. – Temperature) Capacity Lost (mAh) LiCoO2 Carbon Full Cell Capacity Loss (mAh) 150-RT 53.061 46.947 107 150-45 70.744 68.046 125 150-55 98.996 110.773 168 300-RT 130.390 157.719 182 300-45 144.885 170.379 209 300-55 342.846 423.046 481 CV’s of Sony Cell 2 Scan rate: 0.1 mV/sec Current (A) 1 Room Temperature 0 -1 Fresh 800 cycles -2 2.0 2.5 3.0 3.5 Voltage (V) CV-fullcell-fresh and 800 cycles-RT 4.0 4.5 CV’s of Sony Cell 2 Scan rate: 0.1 mV/sec Current (A) 1 0 Fresh-RT Fresh-45 800-RT 800-45 -1 -2 2.0 2.5 3.0 3.5 Voltage (V) 4.0 4.5 XRD Patterns of LiCoO2 after Different Charge-Discharge Cycles Cell c/a Fresh 5.103 150-RT 5.077 300-45 150-45 5.066 300-RT 150-55 4.995 300-RT 4.998 300-45 4.995 300-55 4.985 Intensity 300-55 150-55 150-45 150-RT Fresh 20 30 40 50 2 60 70 Variation of Lattice Constants with Cycling and Temperature Decrease in c/a ratio leads to decrease in Li stoichiometry* c/a 5.10 5.05 RT 45 deg C 55 Deg C 5.00 0 100 200 Cycle Number *G. 300 Ting-Kuo Fey et al., Electrochemistry Comm. 3 (2001) 234 Capacity Fade Loss of Li (Primary Active Material) Degradation of C, LiCoO2 (Secondary Active Material) SEI Formation Electrolyte Oxidation Salt Reduction PF6 2e 3Li 3LiF PF3 Overcharge Solvent Reduction CH3CHOCO2CH 2 2e 2Li CH3CHCH2 Li2CO3 Structural Degradation Conclusions Capacity fade increases with increase in temperature. For all cells decrease in rate capability with cycling is associated with increased resistance at both electrodes. Both primary (Li+) and secondary active material (LiCoO2, C) are lost during cycling. The fade in anode capacity with cycling could be due to repeated film formation. XRD reveals a decrease in Li stoichiometry at the positive electrode with cycling. Acknowledgements This work was carried out under a contract with Mr. Joe Stockel, National Reconnaissance Office for Hybrid Advanced Power Sources # NRO-00-C-1034.