Commercial Horticulture Production Week 7 Protection

advertisement

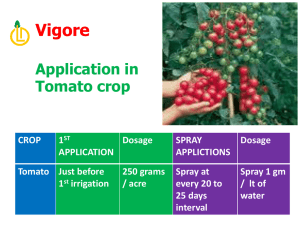

Composition, Activity and Persistence of Crop Protection Chemicals and Biological Agents Graeme Cross, CAFRE Why are Pesticides Necessary? It is estimated that, even today, more than 40% of global food production is lost to pest and disease attack Most major losses affect the staple crops e.g. • Rice • Wheat • Maize • Cassava • Beans/Pulses What is a Pesticide (Plant Protection Product)? Herbicide Weed killer Fungicide Fungal (disease) controller Bactericide Bacteria (disease) controller Insecticide Insect (pest) killer Acaricide Mite/spider (pest) killer Rodenticide Rat / Mouse killer Plant Growth Regulator Growth habit alteration What makes a substance dangerous (hazardous)? • Caustic / Corrosive / Reactive • Flammable • Explosive • Poisonous • Irritating (to skin/ eyes/ respiration) FACT: Some early pesticides contained heavy (toxic) metals e.g. As, Hg, Pb. Q: Why were these products withdrawn (also why are they still very effective)? Toxic metals are poisonous in low doses, accumulate readily in animal tissues (fat, brain) and cannot be metabolised into harmless compounds easily. They often attack a range of different life functions and remain toxic in almost every form that they exist. What are Pesticides (PPPs) made up of ? Active Ingredient [chemical molecule(s)] + Solvent (sometimes acts as stabiliser) + = Activators or other Adjuvants [Additives] + Carrier Substance [clay minerals or inert liquid(s)] F O R M U L A T I O N What is a pesticide FORMULATION? The formulation is made up of What does the FORMULATION achieve? active ingredient + carrier + Keeps the AI in a storable and useable form additives (adjuvants) Eases the dilution / mixing Maximises the effectiveness of application Maintains stability of the product before during and after use Why might different FORMULATIONS be used for the same A.I.? Crop type (which part of the plant or tissue being treated) Growing conditions Environmental considerations Application method (water availability?) SOME COMMON ADJUVANT TYPES AND THEIR ACTIVITY WHAT IS AN ADJUVANT? A substance other than water which is not in itself a pesticide but which enhances or is intended to enhance the effectiveness of the pesticide with which it is used". TYPES OF ADJUVANTS Wetters, Stickers, Spreaders, Penetrants, Extenders (drift retardants) CURRENT SIGNIFICANCE TO CROP PROTECTION Surfactant usage in agrochemicals is estimated at no more than 4% of total world consumption. What other applications would you envisage? Types of product FORMULATION – Quick Quiz DP Dustable Powder EC Emulsifiable Concentrate SC Suspension Concentrate RB Ready to Use Bait SP Soluble Powder WG Water Soluble Granule WB Water Soluble Bag Which are the most dangerous formulations in use? (Discuss briefly) Persistence – a Good or a Bad Thing? In the Crop In the ‘Target’ In the Immediate Environment In the Wider Environment What Governs the Persistence of a PPP? Dosage rate – how much to start with? Environmental Conditions: Temperature Light levels Moisture Humidity Chemical Stability (‘half life’) Soil Type / Growing Medium (adsorption & immobilisation) Growth Stage of Crop (dilution in vivo) Formulation Microbial Activity (biosphere) DELTAMETHRIN A synthetic pyrethroid insecticide / acaricide (cf. pyrethrin) Nerve agent Fast knockdown and highly lipophilic Degrades rapidly in water, air and light Broad spectrum activity Repellent effect [Other pyrethroids = cypermethrin, cyfluthrin, flumethrin, lambda-cyalothrin, permethrin] DIFLUBENZURON A benzoyl urea (benzamide) insecticide Inhibits chitin synthesis (exoskeleton formation) Selective action best targeting soft bodied insects Stable in acidic solutions, soil and dry leaf (half-life between 4 days and 4 months) Persistent activity (H.I. 14 days +) Pest feeding inhibited after contact [Other benzoylurea insecticides include chlorfluazuron, flufenoxuron, hexaflumuron, and lufenuron - ‘Frontline’] PROCHLORAZ A imidazole, dimethylation-inhibiting (DMi) fungicide Site specific action in fungal membrane disruption Prochloraz-manganese complex used for WP formulations Harvest Interval = 4 days ‘Cobweb’ strains exist with reduced susceptibility (Ireland?) Max Individual Dose = 120g/100m2 area Max number of treatments = 2 x M.I.D. or 3 x reduced dose rate of 60g/100m2 [Other triazole fungicides include imidazole, fenbuconazole, penconazole, tebuconazole] The Role of Biological Agents A critical component of Integrated Pest Management (IPM) “A living organism used to control or modify the behaviour of a pest, or to compete with a disease organism” Mushroom examples: •Steinernema feltiae (‘Entonem’) nematode against Sciarid Fly •Metarhizium anisopliae fungus (‘Met52’) against fly pests Biological Agents – Pros and Cons • A non-chemical option: • Cost - Operator safety (handling + use) - No residues • Co-ordination/forward planning needed - Order as required (no storage) • Require the ‘host’ to be present • They target the specific problem • Narrow range of optimal conditions • They have a ‘green’ perception • Lag time before benefit shows • They may last through the production cycle • Lifespan of product is often limited Pesticide Use – Some Practical Implications • Operator Competence: - Training and CPD points - The Voluntary Initiative • Application Criteria and Compliances: - Maximum Treatment Numbers - Maximum Individual Doses - Harvest Intervals - Maximum Residue Levels (pesticide residue testing) • H&S, Worker Welfare, Food Standards, QA, Environmental Protection = DUTY OF CARE! The Issue of Resistance “Where an active ingredient (chemical) becomes less effective, due to an increased ability of the pest or disease to tolerate exposure.” Arises due to: Inappropriate application rates or dosages used Over-reliance on a single A.I. (or a limited range) for control Application of Crop Protection Chemicals (with examples taken from Production of Mushrooms) Graeme Cross, CAFRE What Does the Law Say? A great deal, but almost exclusively relating to: Commercial practice Professional usage Farming Horticulture Contractors Employers and Employees i.e. ‘domestic’ garden operations are not subject to these same laws (apart from consumer protection aspects and ‘wilful pollution’ incidents) Major Legislation Relevant to Use of PPPs • Health and Safety at Work Order (NI) 1978 - overarching employer obligation to ensure worker welfare • Food and Environment Protection Act 1985 [FEPA] - food, human health and environmental protection - safe, reasonable pest control methods • Control of Pesticides Regulations (NI) 1987 (as amended) [COPR] - added under FEPA, specific to PPPs e.g. MAPP register - 1991 & 2005 PPP Regulations for EU standardisation Major Relevant Legislation (cont.) • Control of Substances Hazardous to Health Regulations (NI) 2003 - legal obligation to assess risk and implement adequate controls - not confined to PPPs • Personal Protective Equipment at Work Regulations (NI) 1993 - reinforces the provision of correct (fit) PPE in all professions - clarifies the obligations and responsibilities for all parties • Groundwater Regulations (NI) 2009 - from EC Directive 2006/118/EC on protection of (drinking) water supplies against pollution and deterioration (originally 2000/60/EC) - serious implications on field use of persistent materials e.g. IPU Pesticide Use – Some Practical Implications • Operator Competence: - Training and CPD points [COPR] - The Voluntary Initiative [not law yet!] • Application Criteria and Compliances: [FEPA, COPR, PPPR, etc.] - Maximum Treatment Numbers - Maximum Individual Doses - Harvest Intervals - Maximum Residue Levels (pesticide residue testing) • H&S, Worker Welfare, Food Standards, QA, Environmental Protection = DUTY OF CARE! [e.g. COSHH] Operator Competence – More Detail • National Proficiency Test Council (NPTC) coordinates: - Pesticide Application (PA) Certificates for anyone involved in handling, distributing, storing, measuring and/or applying PPPs - PA1 is the foundation module for all those responsible for handling PPPs as part of their professional duty - PA2a is the technical unit for operating a boom sprayer - PA3a relates to operating an orchard (air-assisted) vertical sprayer - PA4 relates to operating a granule or pellet applicator - PA6 relates to operating a knapsack sprayer • In NI, DARD (CAFRE) has responsibility for delivery of training and assessment in these units (NB. Sustainable Use Directive, November 2015) The Voluntary Initiative (V.I.) • • UK Launch in 2001 Proactive industry (primary producer) response to - threat of further legislation and - increased taxation on PPPs • 3 main tenets (pillars): (i) National Register of Sprayer Operators (NRoSO) (ii) National Sprayer Testing Scheme (NSTS) (iii) Crop Protection Management Plan (CPMP) on farm • Additional measure through BASIS: - Biodiversity and Environmental Training for Advisors (BETA) How Effective is the V.I.? In 2011 (10th anniversary): • 20 359 NRoSO members (£17 annual fee payable) • 14 200 NSTS sprayer tests conducted (c. £100 fee per test) • NSTS compliant sprayers represent approx. 86% of total sprayed agricultural area • 1.35 million Ha covered by a CPMP (free of charge) • Target for CPMP inclusive area was 1.5 m Ha Professional Agronomy Advice Where should you seek guidance? • Always read the product label! (information on approved uses, recommended rates and limits, tank mixes/ compatibilities, correct PPE to wear, harvest intervals for crops, minimum buffer zones, etc.) • Your agronomist, agrochemical merchant and/or DARD adviser should be BASIS qualified (certificated and up-todate in CPD points) • Manufacturers have technical support resources through websites and contact numbers Hierarchies of Risk Control (H&S) 1. Eliminate the hazard at source A. PROCEDURAL 2. Reduce or Substitute the hazard at source (planning ahead) 3. Remove (Separate) the operator from the hazard B. TECHNICAL 4. Contain (Enclose) the hazard (engineering) 5. Limit operator exposure 6. Use P.P.E. C. BEHAVIOURAL (the human factor) COSHH Assessments These relate only to substances (but not just PPPs) in the workplace All employers (inc. self-employed) should carry out COSHH assessment All businesses of > 5 employees must have them recorded and available COSHH assessments should be kept up-to-date A particular COSHH should be revised when any operational or material change occurs How to undertake a COSHH Assessment 1. List the tasks in your workplace that use (or generate) hazardous substances 2. For each task, identify the (type) of substance involved e.g. dust/powder, gas/vapour/smoke, liquid, filings, foam, spore. 3. Determine the hazard (if any) associated with each substance identified 4. Consider the reasonable precautions and control measures that you can implement during the operation, to minimise risk and to control exposure 5. Decide what will be put in place, record this action plan and keep on file for all operators’ information and training What PPPs might be applied in mushroom prodn? Type of product An insecticide Formulation(s) Emulsifiable Concentrate or Oil in Water Emulsion A fungicide A biological control agent A rodenticide A herbicide e.g. glyphosate Wettable Powder Granule or Dispersible Concentrate Ready to Use Bait e.g. SL Application Equipment & NPTC PA Tests Relevant to mushroom production: Hand held applicator with hydraulic nozzle / rotary atomiser (knapsack) = PA6d Hand held applicator with minimum calibration = PA6a Fogging misting and smoke applicators = PA9 The Principle of Hand-Held Application Spray liquid (at correct concentration) ejected under pressure through a narrow aperture i.e. a nozzle of known characteristics What sort of spray quality can you expect? Factors Affecting Spray Application (Quality) • The effect of output pressure • The relationship between droplet size and coverage (4/3 Π r3) • The type of nozzle (single) and arrangement (multiple): e.g. flat fan, even flat fan, hollow cone, solid cone • The nature of the spray liquid e.g. a.i., solvent, adjuvants Nozzles Calibration of Equipment – Why? To ensure uniform, consistent, predictable, measured applications How? For a predetermined test area: (i). (ii). (iii). (iv.) Measure the nozzle output at a set pressure reading (the maximum?) Measure forward speed (or work rate) using water only Calculate apparatus output / square metre Check against product recommendations (and adjust if necessary!) How Much Active Ingredient? A dilute spray solution of prochloraz (‘Sporgon 50WP’) fungicide is needed to treat a mushroom crop. Q1. Give brief, practical reminder points on the correct way to make up this solution. The ‘Sporgon 50WP’ solution has been made up using 120g of product in 240 litres water. Q2. What is the concentration of active ingredient in the spray solution? The grower wishes to treat the crop at the reduced dose rate of 60g product per 100m2 production area. Q3. What volume of spray solution should be applied per square metre? Q4. Minimum product quantity for 240 litre solution, to comply with label? What Should Application Records Include? Location (site/field/tunnel.) ____________ Crop Type _________________ Initials / signature Operator ID Dose Rate/ Qty/litre AI Environmental Conditions Harvest Interval Application Method Reason for Use Active Ingredient Product Name Date Assessing Wind Speed (The Beaufort Scale) F0 = no wind, F1 = 1-3 mph (avg), F2 = 4-7 mph, F3 = 8-12 mph What Other Records / Reference Materials Should be Held? • Emergency Action Plans (fire, spillage, pollution) • Staff Health Audits, if appropriate • Accident Record Sheets (not a book) – 10+ employees and RIDDOR 1995 compliance • PPP label copies, Safety Data Sheets & EAMU (SOLA) print-outs, as needed • PPP stock records/inventory – up-to-date! • Residue tests if available or protocol records for traceability Spray Application Recording Exercise: • Transfer the relevant information from the paragraph below to your spray application record sheet: Last Saturday (6th December 2014) you decided to treat the 4 Ha ‘Meadow Field’ with 1 litre/ha of azoxystrobin fungicide (Brand Name “Amistar”), to control the development of Sclerotinia Stem Rot fungus. You started this job at 10.00 a.m. and it took 90 minutes in total. The weather conditions were dry, overcast and mild (with a light breeze). The pump of the boom sprayer you used was set at an operating pressure of 6 bar (c. 87 psi) and it delivers 250 litres/ha of spray solution (at your usual forward drive speed).