Treatment of dental caries

advertisement

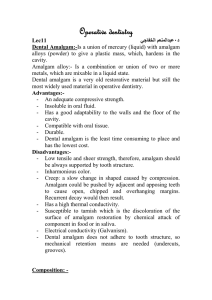

Treatment of dental caries: AMALGAM. Properties, indications, inserting, carving, polishing. 3.Year - DM AMALGAM Amalgam is the most widly used permanent filling in dentistry. It is prepared by mixing the alloy with mercury. The reaction between mercury and alloy is termed an amalgamation reaction. It results in the formation of a hard restorative material of silvery – grey appearance Amalgam Use and Benefits Dental amalgam, in widespread use for over 150 years, is one of the oldest materials used in oral health care. Its use extends beyond that of most drugs, and is predated in dentistry only by the use of gold. Dental amalgam is the end result of mixing approximately equal parts of elemental liquid mercury (43 to 54%) and an alloy powder (57 to 46%) composed of silver, tin, copper, and sometimes smaller amounts of zinc, palladium, or indium. Amalgam MERCURY (Hg) – is a liquid at room temperature and it is able to form a workable mass when mixed with the alloy. The reaction between mercury and alloy is termed an amalgamation reaction. Dental amalgam has been used for many years with a large measure of success. It is the most widely used of all available filling materials. Composition The composition of the alloy powder particles varies from one product to another. Composition of CONVENTIONAL AMALGAM ALLOY: Metal: Weight: Silver (Ag) .......................... 65% min. Tin (Sn) ..............................29% max. Copper (Cu) ..............................6% max. Zinc (Zn) ...............................2% max. Mercury (Hg) ............................ 3% max. Composition 1. Silver - Increases strength, expansion and reactivity. Decreases creep. Corrosion products are AgCl and AgS. 2. Tin - Increases reactivity and corrosion. Decreases strength and hardness. Corrosion products are SnO, SnCl, and SnS. 3. Copper - Increases strength, expansion and hardness. Decreases creep. Corrosion products are CuO and CuS. Composition 4. Zinc - Increases plasticity, strength and the Hg:alloy ratio. Decreases creep. Causes secondary expansion. Corrosion products are ZnCl and ZnO. 5. Mercury - Wets the alloy particles. Decreases strength if in excess amounts. Implicated in toxic and allergic reactions. Effects on properties of an amalgam restoration imparted by ingredients. PROPERTY INGREDIENT Silver Strength Increases Durability Increases Tin Hardness Copper Increases Expansion Increases Decreases Increases Flow Decreases Increases Decreases Color Imparts Increases Decreases Setting time Workability Cleanliness Zinc Decreases Increases Increases Increases Amalgam The role of zinc (Zn) : is as a SCAVENGER during the production of the alloy. The alloy is formed by melting all the constituent metals together. There are tendency for oxidation to occur. OXIDATION of tin (Sn), copper (Cu) or silver would seriously affect the properties of the alloy and amalgam. Zinc reacts rapidly and preferentially with the available oxygen, forming a slag of zinc oxide (ZnO) which is easily removed. Many alloys contain no zinc. They are described as ZINCFREE ALLOYS. Amalgam: properties 1. DIMENSIONAL CHANGES 2. STRENGTH 3. PLASTIC DEFORMATION (CREEP) 4. CORROSION 5. THERMAL PROPERTIES 6. BIOLOGICAL PROPERTIES 1. DIMENSIONAL CHANGES A large contraction would result in a marginal gap down which fluids could penetrate. A large expansion would result in the protrusion of the filling from the cavity. Zinc reacts readily with water producing hydrogen: Zn + H2O –––––––––––– ZnO + H2 The liberation of hydrogen (H2) causes a considerable expansion. 2. STRENGTH The strength of dental amalgam is developed slowly. It may take up to 24 hours to reach a reasonably high value and continues to increase slightly for some time after that. 15 – 20 minutes after placing the filling , the AM is relatively weak. I tis necessary, to instruct patients not to apply undue stress to their freshly placed AM fillings. There is good correlation between strength and mercury content. Optimum properties are produced for amalgams containing 4448% mercury. 3. PLASTIC DEFORMATION (CREEP) Amalgam undergoes a certain amount of plastic deformation or creep when subjected to dynamic intra-oral stresses. The gamma 2 phase of AM is responsible for the relatively high values of creep. The copper- enriched amalgams, which contain little or no gamma 2 in the set material, have significantly lower creep values Gamma 2 phase is responsible for high creep. 4. CORROSION Corrosion is a matter which may significantly affect the structure and machanical properties. The heterogeneous, multiphase structure of AM makes it prone to corrosion. The gamma 2 phase of a conventional AM is the most electrochemically reactive and readily forms the anode in an electrolytic cell. The rate of corrosion is accelerated if the AM filling contacts a gold restoration. Smooth surfaces are less prone to concentration cell corrosion. 5. THERMAL PROPERTIES AM has a relatively high value of thermal diffusivity Dentine is replaced by a good thermal conductor. The coefficient of thermal expansion value for AM is about three times greater than that for dentine. This results in considerably more expansion and contraction in the restoration than in the surrounding tooth when a patient takes hot or cold food or drink. Thermal expansion may cause microleakage around the fillings since is no adhesion between AM and tooth substance. Microleakage plays an important part in initiating such lessions. 6. BIOLOGICAL PROPERTIES Certain mercury compounds are known to have a harmfull effect on the central nervous system. Some studies have shown a higher concentration of mercury in the blood and urine of patients with AM fillings than those without. Another potential problem concerns allergic reactions, usually manifested as a contact dermatitis. Mercury or freshly mixed AM should never be touched by hand. Mercury is readily absorbed by the skin. Usage and preparation of amalgam The dental specialist has the direct responsibility for the correct preparation and use of amalgam. Incorrect use may produce a faulty restoration that can cause or contribute to the loss of a tooth. Therefore, the dental specialist must use extreme care in preparing a good mix of amalgam that will provide the best qualities obtainable from the alloy. MANIPULATIVE VARIABLES The manipulating of AM involves the following sequence of events: 1. Proportioning and dispensing 2. Trituration 3 Condensation 4.Carving 5. Polishing 1. PROPORTIONING AND DISPENSING Alloy/mercury ratios vary between 5:8 and 10:8. Those mixes containing greater quantities of mercury are „wetter“ and are generally used with hand mixing. Those mixes containing smaller quantities of mercury are „drier“ and are generally used with mechanical mixing. Spherical particle alloys,for example , require less mercury to produce a workable mix. 1. PROPORTIONING AND DISPENSING For optimum properties, the final set amalgam should contain less than 50% mercury. The optimal final mercury content ranges from an average of 45% for lathe-cut materials to an average of 40% for spherical materials. 2. TRITURATION The mixing or trituration of AM may be carried out by hand or in an electrically powdered machine which vibrates a capsule containing the mercury and alloy. Trituration by hand is not extensively practised in developed countries nowadays. Mechanical mixing is far more widely used - amalgamator. Trituration times 5 - 20 seconds are normal. 2. TRITURATION The advantages of mechanical trituration are as follows: 1. A uniform and reproducible mix is produced. 2. A shorter trituration time can be used. 3. A greater alloy/mercury ratio can be used. Amalgamator 3. CONDENSATION Material is condensed into the prepared cavity using a flat-ended, steel hand instrument called an amalgam condenser. The technique chosen for condensation must ensure the following. 1. Adequate adaptation of the material to all parts of the cavity base and walls. 2. Good bonding between the incremental layers of amalgam 3. Optimal mechanical properties in the set amalgam by minimizing porosity and achieving a final mercury content of 44-48%. 3. CONDENSATION There should be a minimal time delay between trituration and condensation. If condensation is commended too late, the amalgam will have achieved a certain degree of set and adaptation, and final mechanical properties are all affected. There is a good correlation between the quality of an AM restoration and the energy expended by the operator who condenses it. It needs to use a high condensating force. Lower forces are required to condense spherical particle amalgams than lathe-cut materials. Condensing instruments Amalgam carriers and condensers are used for this purpose. 4. CARVING Soon after condensing the AM, the surface layer , which is rich in mercury, is carved away with a sharp instrument. If carving is delayed too long the material may become too hard to carve and there is a danger of chipping at the margins. 4. CARVING Amalgam carvers 5. POLISHING Polishing is carried out in order to achieve a lustrous surface having a more acceptable appearance and better corrosion resistance. The fillings should not be polished untill the material has achieved a certain level of mechanical strength, otherwisw there is a danger of fracture , particularly at the margins. Many products require a delay of 24 hours between placing and polishing. 5. POLISHING AM polishing kits AM polishers Black Dark purple Green Amalgam indications In primary and permanent dentition In stress bearing areas of the mouth Small to moderate - sized cavities in the posterior teeth As a foundation to crowns When oral hygiene is bad When moisture control is a problem When cost is a concern Amalgam contraindications When esthetics is important When pation has a history of allergic reactions to the alloy When cost is not a concern Amalgam filling Amalgam filling