Design cation exchange column

advertisement

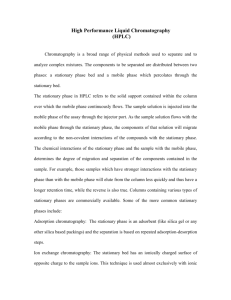

Cation Exchange Column CHEE450 Leslie Davis Cation Exchange • Following removal of biomass – processes supernatant • Separate insulin precursor from glucose, salts & proteins • Sends precursor to the diafilter What is Cation Exchange • • • • • Type of ion exchange chromatography Separates biomolecules Based on electrostatic interactions Charged stationary phase Most widely employed chromatographic separation technique Cation Exchange Chromatography • Employs a negatively charged surface • Separates positively charged solutes • Positively charged proteins (mobile phase) bond to negatively charged stationary phase - + + ++ + + + + + + + - + + + Cation Exchange Chromatography • Protein: ampholytic (+ & -) • pH & isolectric point determine protein surface charge • pH kept below isoelectric point (5.3-5.35) • Cause protein to become Process Considerations • Stationary Phase • • • • Rigid to support high flow rates Provide sufficient selectivity and capacity Not denature protein Stable over a wide range of operating conditions • Amenable to rigorous cleaning • Should not leach materials Process Considerations • SP SepharoseTM Fast Flow Resin • Preparative purification with high flow rates • For purification of crude samples • Easy to scale up • • • • • 6% highly cross-linked agarose 45-165 μm bead size Strong cationic gel Charged group: -CH2CH2SO3- (sulfopropyl) 70 mg ribonuclease A/mL gel Process Considerations • Selection Kits • Screen different ion exchange media • 1 - 5mL columns Process Considerations • Sizing: D/H range between 2 – 4 • Short columns recommended to maximize throughput • Taller columns: cause increase in cycle time and higher pressure drop • Shorter columns: uneven flow pattern and breakthrough of product Column Sizing Required protein throughput Number of columns in parallel Cycle time Operating Gel capacity 442000 g per 24 hours 3 2.5 h 70 g/L Bed Volume Bed Diameter Bed Height 274.06 L 100 cm 40.13 cm D/H ratio Flow Rate Actual volume 2.87 320.31 L/column/h 315.17 L Process • Wasted material: • salts, glucose, biomass, 100% protein contaminants • Buffer • 0.1M acetate (pH 5.0) • Elution • 0.1 M NaOH, 2 M NaCl → 5.3 • 22 kg/batch → 3.2 kg/column/cycle • Cleaning or Column Regeneration • Washing with 0.1M NaOH, 1M NaCl and 50% EtOH Column Selection • Amersham Pharmacia biotech Process Alternatives • Anion exchange • high negative charge and good solubility of protein • Affinity Chromatography • Ultra high resolution, removes bioactive contaminants • Expensive, not readily amenable to scale up and harsh manufacturing environment (CIP) The End Questions?