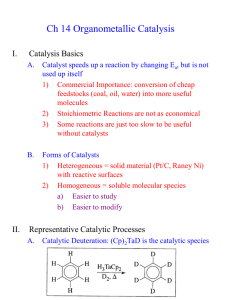

Chemist & Chemical Engineers Hetrogeneous Catalysis ppt

advertisement

Chemists and Chemical Engineers Make the World a Better Place through Modern Developments in Heterogeneous Catalysis Presented by SANJAY PATEL Department of Chemical Engineering Institute of Technology, Nirma University Content Chemistry & Chemical Engineering History of Catalysis Catalysis Recent trends in Catalysis Future trends in Catalysis Summary Chemistry and Chemical Engineering more Integrated to the Society Society: • Cleaner and safer processes • Well accepted and integrated processes Industry: • Speed-up processes • Energy and cost effective processes • New catalysts and catalytic processes • New technologies Academia: • New innovations • Deeper knowledge and understanding of phenomena • Control of phenomena Role of Catalysis in a National Economy • 24% of GDP from Products made using catalysts (Food, Fuels, Clothes, Polymers, Drug, Agro-chemicals) • > 90 % of petro refining & petrochemicals processes use catalysts • 90 % of processes & 60 % of products in the chemical industry • > 95% of pollution control technologies • Catalysis in the production/use of alternate fuels (NG,DME, H2, Fuel Cells, biofuels…) Why R&D in catalysis is important • For discovery/use of alternate sources of energy/fuels/raw material for chemical industry • For Pollution control • For preparation of new materials (organic & inorganic-eg: Carbon Nanotubes) Three Scales of Knowledge Application Some Developments in Industrial catalysis-1 1900- 1920s Industrial Process Catalyst 1900s: CO + 3H2 CH4 + H2O Ni Vegetable Oil + H2 butter/margarine Ni 1910s: Coal Liquefaction Ni N2 + 3H2 2NH3 NH3 NO NO2 HNO3 1920s: CO + 2H2 CH3OH (HP) Fischer-Tropsch synthesis SO2 SO3 H2SO4 Fe/K Pt (ZnCr)oxide Co,Fe V2O5 Industrial catalysis-2 1930s and 1940s 1930s:Cat Cracking(fixed,Houdry) Mont.Clay C2H4 C2H4O Ag C6H6 Maleic anhydride V2O5 1940s:Cat Cracking(fluid) amorph. SiAl alkylation (gasoline) HF/acid- clay Platforming(gasoline) Pt/Al2O3 C6H6 C6H12 Ni Industrial catalysis-3 1950s C2H4 Polyethylene(Z-N) C2H4 Polyethylene(Phillips) Polyprop &Polybutadiene(Z-N) Steam reforming HDS, HDT of naphtha C10H8 Phthalic anhydride C6H6 C6H12 C6H11OH C6H10O C7H8+ H2 C6H6 +CH4 Ti Cr-SiO2 Ti Ni-K- Al2O3 (Co-Mo)/Al2O3 (V,Mo)oxide (Ni) (Cu) (Ni-SiAl) Industrial catalysis-4 1960s Butene Maleic anhydride (V,P) oxides C3H6 acrylonitrile(ammox) Bimetallic reforming (BiMo)oxides PtRe/Al2O3 Metathesis(2C3 C2+C4) Catalytic cracking (W,Mo,Re)oxides Zeolites C2H4 vinyl acetate Pd/Cu C2H4 vinyl chloride CuCl2 O-Xylene Phthalic anhydride Hydrocracking V2O5/TiO2 Ni-W/Al2O3 CO+H2O H2+CO2 (HTS) --do-(LTS) Fe2O3/Cr2O3/MgO CuO-ZnO- Al2O3 Industrial catalysis-5 1970s Xylene Isom( for p-xylene) H-ZSM-5 Methanol (low press) Cu-Zn/Al2O3 Toluene to benzene and xylenes H-ZSM-5 Catalytic dewaxing H-ZSM-5 Autoexhaust catalyst Pt-Pd-Rh on oxide Hydroisomerisation Pt-zeolite SCR of NO(NH3) V/ Ti MTBE C7H8+C9H12 C6H6 +C8H10 acidic ion exchange resin Pt-Mordenite Industrial catalysis-6 1980s Ethyl benzene H-ZSM-5 Methanol to gasoline H-ZSM-5 Vinyl acetate Pd Improved Coal liq NiCo sulfides Syngas to diesel Co HDW of kerosene/diesel.GO/VGO MTBE cat dist Oxdn of methacrolein N-C6 to benzene Pt/Zeolite ion exchange resin Mo-V-P Pt-zeolite Industrial catalysis-7 1990s DMC from acetone Cu chloride NH3 synthesis Ru/C Phenol to HQ and catechol TS-1 Isom of butene-1(MTBE) H-Ferrierite Ammoximation of cyclohexanone TS-1 Isom of oxime to caprolactam TS-1 Ultra deep HDS Olefin polym Co-Mo-Al Supp. metallocene cats Ethane to acetic acid Fuel cell catalysts Cr-free HT WGS catalysts Multi component oxide Rh, Pt, ceria-zirconia Fe,Cu- based Industrial catalysis-8 2000+ • Solid catalysts for biodiesel - solid acids, Hydroisom catalysts • Catalysts for carbon nanotubes - Fe (Ni)-Mo-SiO2 For Developed Catalysts MAINLY IMPROVEMENT IN PERFORMANCE by New Synthesis Methods & use of PROMOTERS Green Chemistry is Catalysis • Pollution control (air and waste streams; stationary and mobile) • Clean oxidation/halogenation processes using O2,H2O2 (C2H4O, C3H6O) • Avoiding toxic chemicals in industry (HF,COCl2 etc) • Fuel cells (H2 generation) Latest Trends Catalysis in Nanotechnology Methods of Catalyst preparation are most suited for the preparation of nanomaterials • Nano dimensions of catalysts • Common prep methods • Common Characterization tools • Catalysis in the preparation of carbon nanotubes Latest Trends Catalysis in the Chemical Industry • Hydrogen Industry(coal,NH3,methanol, FT, hydrogenations/HDT,fuel cell) • Natural gas processing (SR,ATR,WGS,POX) • Petroleum refining (FCC, HDW,HDT,HCr,REF) • Petrochemicals (monomers,bulk chemicals) • Fine Chem. (pharma, agrochem, fragrance, textile,coating,surfactants,laundry etc) • Environmental Catalysis (autoexhaust, deNOx, DOC) Latest Trends HETEROGENEOUS CATALYSIS AN INRODUCTION Steps of Catalytic Reaction - Diffusion of Reactants (Bulk to Film to Surface) - Adsorption - Surface Reaction - Desorption & Diffusion of Products porous carrier (catalyst support) bed of catalyst particles reactants substrate product reactor reaction desorption adsorption products catalyst support active site Role of Chemists & Chemical Engineers Team Work Catalysts Preparation Wet impregnation: • Preparation of precursors (Cu & Zn-nitrates) solution • Impregnation of precursors on alumina support • Rotary vacuum evaporation • Drying • Calcination • Reduction Rotary vacuum evaporator Nitrate Salts solution & Alumina pellets Catalysts Preparation 0.5M Na2CO3 Dropwise addition Wet Impregnation Co-precipitation Nitrate Salts Solution 70 oC, pH=7-8 Mixer cum shaker Precipitates: Ageing for 2 h Round bottom flask with Heating mental & Agitator Crushing Catalyst Rotary Vacuum Evaporator Sieving, 20/25 mesh Filteration Drying @ 125 oC for 12 h Calcination, 350 oC for 4 h Drying @ 125 oC for 12 h Pelletizing Catalyst Crushing Sieving, 20/25 mesh Crushing Calcination, 350 oC for 4 h Calcined WI CuO/ZnO/Al O Catalyst Calcined WI CuO/ZnO/Al O Catalyst Co-precipitation Co/Al2O3 Calcined Commercial Ni/Al2O3 Spent Commercial Ni/Al2O3 Commercial Fe2O3 catalyst Spent Commercial Fe2O3 catalyst Auto-catalysts Pt, Pd and Rh on the Metox metallic substrates Pervoskite LATEST Research Honey Comb Catalysts CATALYST CHARACTERIZATION • Bulk Physical Properties • Bulk Chemical Properties • Surface Chemical Properties • Surface Physical Properties • Catalytic Performance Bulk Chemical Properties • Elemental composition (of the final catalyst) • XRD, electron microscopy (SEM,TEM) • Thermal Analysis(DTA/TGA) • NMR/IR/UV-Vis Spectrophotometer • TPR/TPO/TPD • EXAFS Surface Properties • XPS,Auger, SIMS (bulk & surface structure) • Texture :Surface area- porosity • Counting “Active” Sites: -Selective chemisorption (H2,CO,O2, NH3, Pyridine,CO2);Surface reaction (N2O) • Spectra of adsorbed species (IR/EPR/ NMR / EXAFS etc) Physical properties of catalysts • Bulk density • Crushing strength & attrition loss (comparative) • Particle size distribution • Porosimetry (micro(<2 nm), macro(>35 nm) and meso pores Catalysts Characterization Characteristics Methods Surface area, pore volume & size N2 Adsorption-Desorption Surface area analyzer (BET and Langmuir) Pore size distribution BJH (Barret, Joyner and Halenda) Elemental composition of catalysts Metal Trace Analyzer / Atomic Absorption Spectroscopy Phases present & Crystallinity X-ray Powder Diffraction TG-DTA (for precursors) Morphology Scanning Electron Microscopy Catalyst reducibility Temperature Programmed Reduction Dispersion, SA and particle size of active metal CO Chemisorption, TEM Acidic/Basic site strength NH3-TPD, CO2 TPD Surface & Bulk Composition XPS Coke measurement Thermo Gravimetric Analysis, TPO BET Surface Area Analyzer Major role of Chemical Engineer with Chemists for Hardware Surface area, Pore Volume, Pore Size & Pore size distribution Surface Area and Pore size Distribution 7.0E-3 CZCEA2 P2CZCeA P2CZCeA 180 6.0E-3 g -1 A0-1 160 140 CZA2 5.0E-3 3 120 100 Pore volume, cm 3 -1 Volume adsorbed, cm g (STP) 200 80 60 40 20 4.0E-3 3.0E-3 2.0E-3 P3CZA 1.0E-3 0 0 100 200 300 400 500 600 700 000.0E+0 10 Relative pressure, P/P 0 100 Pore diameter, A 1000 0 N2 adsorption/desorption Isotherm Pore size distribution by BJH method Barret, Joyner, and Halenda (BJH) P2CZCeA Cu/Zn/Ce/Al:30/20/10/40 P3CZA Cu/Zn/Al:30/20/50 P 2 Vm COS ln P0 rk RT Chemisorption Analyzer Dispersion, Metal Surface area and Metal Particle size; TPR, TPO, TPD TGA/DTA Analyzers Coke measurement & TPO Reactions involved in SRM process CH3OH + H2O ↔ CO2 + 3H2 CO2 + H2 ↔ CO + H2O CH3OH ↔ 2H2 + CO Reactions involved in OSRM process CH3OH + (1-p)H2O +0.5pO2 ↔ CO2 + (3-p)H2 ∆H0 = (49.5 - 242*p) kJ mol-1 CH3OH + 0.75H2O + 0.125O2 ↔ CO2 + 2.75H2 ∆H0 = -10 kJ mol-1 ∆H300 oC = 0 kJ mol-1 CH3OH + 0.5H2O + 0.25O2 ↔ CO2 + 2.5H2 ∆H0 = -71.4 kJ mol-1 CH3OH + 0H2O + 0.5O2 ↔ CO2 + 2H2 ∆H0 = -192 kJ mol-1 CH3OH + 1.5O2 ↔ CO2 + 2H2O ∆H0 = -727 kJ mol-1 Catalyst Activity Testing • Activity to be expressed as: - Rate constants from kinetics - Rates/weight - Rates/volume - Conversions at constant P,T and SV. - Temp required for a given conversion at constant partial & total pressures - Space velocity required for a given conversion at constant pressure and temp Operating Conditions for SRM & OSRM Parameters Catalyst mass, g 1-3 Contact-time (W/F) kgcat s mol-1 3-15 Temperature, oC 200-300 S/M molar ratio 0-1.8 (SRM) S/O/M molar ratio 1.5/0-0.5/1 (OSRM) Pressure, atm 1 Schematic diagram of OSRM process Vaporizer cum Mixer Methanol & Water Feed Pumps Gas Chromatograph with DAS Packed Bed Catalytic Reactor Chiller FM-1 FM-2 V-1 V-2 FM-3 V-3 Condenser For Catalyst Reduction FM-4 Product Gases G-L Separator Methanol & Water O2 N2 H2 Schematic diagram of OSRM process Vaporizer cum Mixer Methanol & Water Feed Pumps Reactants Inlet Thermocouple Flange OD 25mm Gas Chromatograph with DAS Catalyst bed Packed Bed Catalytic Reactor L 770mm FM-1 FM-2 V-1 V-2 FM-3 V-3 ID 19mm Condenser Chiller For Catalyst Reduction FM-4 Products Product Gases G-L Separator Methanol & Water O2 N2 H2 Characterization and Activities of ZnO & Ceria promoted Catalysts P4CZA P3CZA P1CZCeA P2CZCeA P3CZCeA Cu/Zn/Al Cu/Zn/Al Cu/Zn/Ce/Al Cu/Zn/Ce/Al Cu/Zn/Ce/Al Composition, wt% 30/30/40 30/20/50 30/25/5/40 30/20/10/40 30/10/20/40 BET SA, m2 g-1 92 106 96 108 101 Pore volume, cm3 g-1 0.26 0.32 0.28 0.34 0.29 Cu dispersion, % 9.4 12.8 10.2 19.6 14.8 Cu SA, m2 g-1 18.3 25.1 20.2 38.6 29.3 Cu particle size, Å 108 80 101 52 69 X, % 60 77 69 100 90 180 160 244 217 3400 1400 995 1240 Co-precipitation H2 rate, kgcat-1 mmol CO formation, ppm s-1 132 9400 T=280 oC, W/F=11 kgcat s mol-1, S/O/M=1.5/0.15/1 & P=1 atm At Lab Scale Activity at Kinetically Controlled Conditions Scale-up & Commercialization Major Role of Chemists & Chemical Engineers Examples of Steam Reformer & Ammonia Reactor Primary Reformer Ammonia Converter RECENT TRENDS Big picture: Sustainable Development Green Chemistry Is About... Waste Materials Hazard Risk Energy Cost The drivers of green chemistry Economic benefit Lower capital investment Lower operating costs Societal pressure Government legislation Improved public image Safer and smaller plants Pollution control Less hazardous materials Green chemistry High fines for waste Producer responsibility The 12 Principles of Green Chemistry (1-6) 1. Prevention It is better to prevent waste than to treat or clean up waste after it has been created. 2. Atom Economy Synthetic methods should be designed to maximise the incorporation of all materials used in the process into the final product. 3. Less Hazardous Chemical Synthesis Wherever practicable, synthetic methods should be designed to use and generate substances that possess little or no toxicity to people or the environment. 4. Designing Safer Chemicals Chemical products should be designed to effect their desired function while minimising their toxicity. 5. Safer Solvents and Auxiliaries The use of auxiliary substances (e.g., solvents or separation agents) should be made unnecessary whenever possible and innocuous when used. 6. Design for Energy Efficiency Energy requirements of chemical processes should be recognised for their environmental and economic impacts and should be minimised. If possible, synthetic methods should be conducted at ambient temperature and pressure. The 12 Principles of Green Chemistry (7-12) 7 Use of Renewable Feedstocks A raw material or feedstock should be renewable rather than depleting whenever technically and economically practicable. 8 Reduce Derivatives Unnecessary derivatization (use of blocking groups, modification of physical/chemical processes) should be minimised or avoided if possible, because such steps require additional reagents and can generate waste. 9 Catalysis 10 Design for Degradation Chemical products should be designed so that at the end of their function they break down into innocuous degradation products and do not persist in the environment. 11 Real-time Analysis for Pollution Prevention Analytical methodologies need to be further developed to allow for real-time, in-process monitoring and control prior to the formation of hazardous substances. 12 Inherently Safer Chemistry for Accident Prevention Green Catalytic Processes • Alternative feedstocks, reagents, solvents, products • Enhanced process control • New catalysts • Greater integration of catalysis and reactor engineering: membrane reactors, microreactors, monolith technology, phenomena integration • Increased use of natural gas and biomass as feedstock • Photodecomposition of water into hydrogen and oxygen • Catalysts for depolymerizing polymers for recycle of the monomers • Improvements in fuel cell electrodes and their operation Cleaner and greener Environment: Catalysis New directions for research driven by market, social & environmental needs: • Catalysis for energy-friendly technologies and processes (primary methods) • New advanced cleanup catalytic technologies (secondary methods) • Catalytic processes and technologies for reducing the environmental impact of chemical and agro-industrial solid or liquid waste and improving the quality and reuse of water (secondary methods) • Catalytic processes for a sustainable chemistry (green chemistry and engineering approach) • Replacement of environmentally hazardous catalysts in existing processes How to Decrease the Greenhouse Effect? New catalysts for high output fuel cells • Electricity production via electrocatalytic oxidation of hydrocarbons •Chemical energy of hydrocarbon is converted to electricity Catalysts and processes for solar energy conversion and hydrogen production •CO2 or other greenhouse gases are not emitted into the atmosphere, • First solar energy is converted into the chemical energy of synthesis gas (CO + H2) via the endothermic reaction of methane reforming •Storage of the synthesis gas •The stored energy can be released via the reverse exothermal methanation reaction CO + 3H2 → CH4 + H2O •Efficiency from 43 to 70 % Catalysts are needed for these reactions!!! Classic Route to Ibuprofen H C l, A cO H , A l W aste Ac 2 O Ac O H HCl H 2 O / H+ Cl C H 2 C O 2 Et A l Cl 3 Na O Et C O C H3 Et O 2 C Examples of Green Catalysis OHC O N H2 O H H 2 O / H+ N H O2 C N H3 OHN Hoechst Route To Ibuprofen AcOH HF H2 / Ni CO, Pd Ac2O O HO Examples of Green Catalysis HO2C “The use of auxiliary substances (e.g. solvents, separation agents, etc.) should be minimized” Examples of Green Catalysis Poly lactic acid (PLA) for plastics production Examples of Green Catalysis Polyhydroxyalkanoates (PHA’s) Examples of Green Catalysis ‘TiO2’ A GREEN CATALYST: CLEAN ENVIRONMENT Examples of Green Catalysis Photocatalysis CO2 + H2O CO2 Chlorophyll Photocatalyst Organic Compound H2O Starch + O2 Organic compound + H2O + O2 Photocatalytic Applications Self-Cleaning Effect TiO2 - Photocatalysis 3.12 eV (380 nm) Photocatalytic Reactions TiO2 + h h+ + H2O O2 + eO2 - + H+ HO2 + HO2 O2 - + HO2 TiO2 (e- + h+) OH + H+ O2 - HO2 H2O2 + O2 O2 + HO2- HO2- + H2O2 H2O2 + h 2 OH H2O2 + O2 - H2O2 + e- HO + OH- + O2 HO + OH- Catalytic processes Microreactors – Future • Uniform channel structure, fractal catalyst supports • Scale-up • How microreactor is connected to the macroworld? • Operating regimes • Controlled periodic processing • Programmable reactor • Process control • Miniaturized sensors and actuators • Local feedback and programmable regimes • Advanced structure, materials, process control • Multiscale – finely defined; locally targeted – globally optimized Random Vs Structured Catalysts Random Packed Today Structured Beds of Tomorrow Monoliths (Structured) vs Pellets (Random) Monolith catalyst extruded from commercial catalyst support material Does the configuration alone improve performance? Conventional pellets made from the same material Flowsheet Synthesis 2D & 3D CAD Solids Modeling Multiscale Transport Process Engineering Control Systems Microscale Design Modules Flow Patterns Simulation & Optimization Tools, Fabrication & Assembly Materials of Construction Microprocess Components Component Integration Micro Systems Engineering Multi-scale Transport Micro Process Plant Raw Materials & Feedstocks Chemistry & Catalysis Reaction Kinetics Integrated Sensors Catalyst Characterization Reaction Pathways & Mechanisms Sampling Sensors Data handling & Chemometrics Micro Analyzers (GC, LC, MS, TOF) Micro Process Analytical Micro PAT Systems Integration Some Advantages of Microreactors & Monoliths • High surface-to-volume area; enhanced mass and heat transfer; • high volumetric productivity; • Laminar flow conditions; low pressure drop • Residence time distribution and extent of back mixing controlled – “precise reaction engineering” • Low manufacturing, operating, and maintenance costs, and low power consumption • Minimal environmental hazards and increased safety due to small volume • “Scaling-out” or “numbering-up” instead of scaling-up Some Potential Problems • Short residence times require fast reactions • Fast reactions require very active catalysts that are stable (The two most often do not go together) • Catalyst deactivation and frequent reactor repacking or reactivation • Fouling and clogging of channels • Leaks between channels • Malfunctioning of distributors • Reliability for long time on-stream • Structural issues So far there are only two major commercial uses of micro-channel systems (monoliths) – • Automotive catalytic convectors (major success) • Selective catalytic reduction (NH3 – SCR) of power plant NOx Applications of the Process Utilizing Biomass Streams Process Hydrogen Energy Crops Biomass Waste Aqueous Biomass Stream Extraction Hydrogen APR Extraction PEM Fuel Cell SOFC Fuel Gas APR ICE Genset Microturbine Genset CATALYSIS IN THE PRODUCTION OF FUTURE TRANSPORTATION FUELS Biofuels Life Cycle Technology for Green & Biofuels Biomass Sources For Biofuels • • • • LignoCellulose (Cellulose, Hemicellulose, Lignin) Starch Sugars Lipid Glycerides (Vegetable Oils & Animal Fats) Structures in Lignocellulose Pathways to Renewable Transportation Fuels Gasifier Veg Oils Algae Oils Biomass Pyrolysis Syngas Methanol, Ethanol, FT( diesel,etc) Biodiesel Bio Oils Ferment to ethanol, butanol Refine to Liquid Fuels Gasoline additives Hydrolysis Aqueous phase Reforming Hydrogen Bioethanol Overview - Global • Current bioethanol production in US is 12 billion gallons. • Most cars on the road in US today can run on blends of up to 10% ethanol. • US DOE has estimated that there is a potential to produce over 80 Billion gallons of bio-ethanol from cellulose and hemi-cellulose present in corn biomass in the 9 major US corn producing states. • This equates to over 250 Million tons of bio-ethanol and >$160 Billion revenue. • Iogen’s Demo plant producing cellulosic ethanol from wheat straw in Canada since 2004. • DuPont-Danisco JV has started demonstration of cellulosic ethanol from corncobs since Jan., 2010 in USA. • Brazil currently blends 25% ethanol in gasoline and bioethanol is produced directly from sugarcane. • Brazilian flex cars are capable of running on just hydrated ethanol (E100), or just on a blend of gasoline with 20 to 25% anhydrous ethanol, or on any arbitrary combination of both fuels • China uses 10% bioethanol in gasoline . 2nd Generation Bioethanol Technology Overview Company Location Technology Present Status Hydrolysis based Technology Players DuPontUSA Feed stock - Agri residue. Pilot Plant started Danisco Iogen/ Alkaline pretreatment , enzymatic hydrolysis + C5/C6 Co-fermentation Canada Feed stock – Agri Biomass. Pretreatment – steam explosion. Enzymatic hydrolysis & fermentation of C5/C6 sugars Demo. Plant operating, since 2004. Commercial Plant expected to be commissioned in 2011. Canada Feed stock - wood, agribiomass. Organosolv pretreatment & sepn. Of high purity lignin. Enzymatic hydrolysis and fermentation of C5 & C6 sugars separately Technology proven at Bench scale. Shell Lignol Pilot Scale under Engineering design. Enzymatic based Cellulosic Ethanol Process Biomass Enzyme Production Pretreatment Microbe Hydrolysis C5/C6 Sugars Bioreactor Distillation/ dehydration Lignin Second Generation Bioethanol Ethanol 99.7 wt% Gasification based Technology Players Gasification based Technology Players Company Location Technology Present Status COSKATA USA Completed pilot scale optimization. Feed stock - Agri residue, pet coke, MSW. Gasification to syn-gas & direct fermentation to ethanol. INEOS Bio USA Feed stock - Agri residue, MSW. Conventional Gasification to syn-gas & its fermentation to ethanol. Process under study in pilot plant. Gasification based Cellulosic Ethanol Process Biomass Gasifier Microbe Syn-gas Bioreactor Distillation/ 4 - 6% ethanol dehydration Ethanol 99.7 wt% Transportation Fuels from Cellulosic Biomass (Pyrolysis Route) Transportation Fuels from Biomass BIODIESELS • First generation biodiesel Fatty Acid methyl esters (FAME); methyl esters of C16 and C18 acids. • Second generation Biodiesels “Hydrocarbon Biodiesels” ; C16 and C18 saturated, branched Hydrocarbons similar to those in petrodiesel; High cetane number (70 – 80). • Third Generation Biofuels From (hemi)Cellulose and agricultural waste; Enzyme technology for (hemi) Cellulose degradation and catalytic upgrading of products. First Generation Biodiesels Fatty Acid Methyl Esters • Veg Oil + methanol FAME + glycerine • Catalysts:Alkali catalysts( Na/K methoxides); CSTR; Large water, acid usage in product separation Fuel Quality Problems in First Generation Technology • Lower glycerol purity; Not suitable for production of chemicals (propanediol, acrolein etc) without major purification; Salts and H2O to be removed from Glycerol. • Residual KOH in biodiesel creates excess ash content in the burned fuel/engine deposits/high abrasive wear on the pistons and cylinders. Catalysts for 2nd Generation Biodiesel. “Hydrocarbon Biodiesel “Technology • “Hydrocarbon Biodiesel” consists of diesel-range hydrocarbons of high cetane number • Deoxygenation and hydroisomerization of Veg Oil at high H2 pressures and temp. • Catalysts:NiMo(for deoxyg), Pt-SAPO-11(for isom); H2 at high pressure needed;Yield from VO is lower;C3 credit. • Can be integrated with petro refinery operations;Greater Feedstock flexibility. • Suitable for getting PP < - 20 C (Jet Fuels). • 40000 tpy plant in Finland; 200K tpy in Singapore;100K tpy plant using soya in SA. Convert Veg Oil to HC Diesel in Hydrotreaters in Oil Refineries • Hydrotreat /Crack mix of VO + HVGO(5-10%); S=0.35%;N(ppm)= 1614;KUOP = 12.1; density=0.91 g/cc);Conradson C = 0.15%; Sulfided NiMo/Si-Al Catalyst; ~350C,50 bar; LHSV = 5; Diesel yield ~ 75%wt. • Advantages over the Trans Esterificat Route - Product identical to Petrodiesel (esp.PP ) - Compatible with current refinery infrastructure - Engine compatibility; Feedstock flexibility Capital Costs : EIA Annual Energy Outlook 2006 107 Natural gas to Transportation Fuels : Options • Natural Gas Syngas • I. Syngas Methanol (DME) Gasoline • II. Syngas Fischer-Tropsch Syndiesel Syndiesel Can use existing infrastructure • III. Syngas H2 Fuel Cell – driven cars: Stationary vs On-board supply options for Hydrogen • Natural Gas Electricity;MCFC and SOFC can generate electricity by direct internal reforming of NG at 650C;Ni/ Zr(La)Al2O4, loaded on anode Catalysts for conversion of NG to Transportation Fuels I.Syngas Preparation - Hydrodesulphurisation(Co/Ni-Mo-alumina) - Syngas generation(H2/ CO); POX, steam, autothermal, “dry” reforming; Ni(SR),Ru(POX) – based catalysts; Pt metals for POX for FT. 2.Fischer Tropsch Synthesis: Co – Wax and mid dist; Fe - gasoline; Cu & K added. Supported Co preferred due to its lower WGS activity & consequent lower loss of C as CO2. 3.Product Work up: Wax Conversion to diesel and gasoline. Mild Hydro-cracking/Isom catalysts (Pt metal- acidic oxide support ) Petroleum - vs- Syngas :: Diesel Property PetroSynBoiling Range,oC 150-300 150-300 Density at 15 C,kg/m3 820-845 780 S, ppm vol 10 - 50 <1 Aromatics,% vol 30 <0.1 Cetane No >51 >70 CFPP, oC -15 -20 Cloud point,oC -8(winter) -15 Due to lower S, N and aromatics, GTL diesel generates less SOx and particulate matter. Power and fuels from Coal / PetCoke Gasification Texaco EECP Project FEED:1235 TPD OF PetCoke PC SG (75%)Power Plant 25%FT fuel(tail gas Power) • 55 MW Electricity; Steam. • 20 tpd diesel; 4 tpd naptha • 82 tpd Wax(60 tpd diesel); 89 tpd S; • H2: CO = 0.67;Once-thru slurry(Fe) FT reactor; RR = 15 % at a refinery site. Coal To Syngas To Fuel Cells Catalysis in Coal / PetCoke gasification • SR: C + H2O CO + H2 (+117 kJ/mol) Combust:2C+ O2 2CO (H = -243 kJ/mol) WGS :CO + H2O H2 + CO2 ( -42 kJ/mol) Methan: CO+3 H2 CH4 + H2O(- 205 kJ/mol) • Methanation can supply the heat for steam gasification and lower oxygen plant cost. K & Fe oxides lower temp of gasification • H2/CO ~0.6 in coal gasification;Good WGS is needed; • MCFC and SOFC can use H2,CO, & CH4 as fuel to generate electricity. • Low rank coals, Lignites gasify easier. Hydrogen Production Costs (The Economist / IEA) SOURCE USD / GJ Coal / gas/ oil/ biodiesel 1-5 NG + CO2 sequestration 8-10 Coal + CO2 sequestration 10-13 Biomass(SynGas route) 12-18 Nuclear (Electrolysis) 15-20 Wind (Electrolysis) 15-30 Solar (Electrolysis) 25-50 Sugar Cane Juice to H2 AQUEOUS PHASE REFORMING • C6H12O6 +6H2O 12H2 +6CO2(APR) • Pt-alumina catalysts, 200 oC • 1 kg of H2 ($3-4) from 7.5 kg Sugar Fuel Efficiency of H2 >> diesel/gasoline H2 Production from Glycerin • Available from Veg oils(40-98% in H2O) • C3H8O3 +3H2O 7H2 + 3CO2 • Ru – Y2O3 catalysts; 600 oC • 1 kg H2 from 7 kg glycerine H2 production from Biomass is less economically viable than production of ethanol and biodiesel from biomass. Catalytic Direct Methane Decomposition to H2 and Carbon Nanotubes Catalytic Auto Thermal Reforming of Methanol, Ethanol, DME to HYDROGEN for FUEL CELL Pure H2 Supply • Compressed H2 • Liquid H2 • H2 Hydride H2 Fuel H2 from Reformed liquid HC • Methanol • Ethanol • DME H2 Combustion Engine Similar to Gasoline Internal Combustion Engine Pure H2 Supply • Compressed H2 • Liquid H2 • H2 Hydrid PEM Fuel Cell H2 Fuel H2 from Reformed liquid HC • Methanol • Ethanol • DME Pure H2 Supply • Compressed H2 • Liquid H2 • H2 Hydrid PEM Fuel Cell H2 Production H2 from Fossil & Renewable Fuel Sources H2 from Reformed liquid HC • Methanol • Ethanol • DME Catalysts for H2O and CO2 Photothermal Splitting Using Sunlight 1. H2O H2 + 0.5 O2 2. CO2 CO +0.5 O2 • FT Synthsis: CO + H2 (CH2)n petrol/Diesel Sandia’s Sunlight To Petrol Project: Cobalt ferrite loses O atom at 1400o C; When cooled to 1100o C in presence of CO2 or H2O, it picks up O, catalyzing reactions 1 and 2; Solar absorber provides the energy. Challenge: Find a solid which loses / absorbs O from H2O / CO2 reversibly at a lower temp. Splitting H2O 124 Splitting H2O with visible light 125 Future Fuels: Catalysis Challenges • Meeting Specifications of Future Fuels Remove S,N, aromatics, Particulate Matter • Power Generation - Lower CO2 Production in Catalytic Gasification - Lower CO2 and H2/CO ratio in Syngas generation • FT Synthesis: Lower CH4 and CO2 ;Inhibit metal sintering; Increase attrition strength; Reactor design • Biomass:1.Cellulose to Ethanol ( enzymes) 2. Biomass gasification catalysts. Decentralized Production/ Use of H2 and Biofuels will avoid costs due to their storage and distribution. “Holy Grail “ Challenges • Direct Conversion of CH4 to methanol and C5+. • Catalytic Water and CO2 splitting using solar energy Thanks Discussion