MS PowerPoint

advertisement

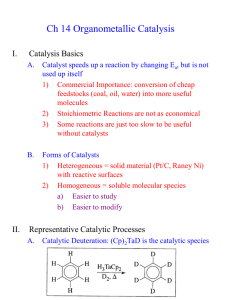

A Most Efficient Oxygen Reduction Electrode Is this realizable? 1 INTRODUCTION Electrons Air/O2 Importance of electrochemical reduction of oxygen Fuel Cells Metal-Air batteries Industrial electrolytic processes H+ H+ H+ H+ H+ Water H+ Oxygen reduction reaction (ORR) is a four electron process: O2 + 4 H+ + 4 e- → 2 H2O Eo = 1.229 V vs. NHE Cathode 2 Reaction pathways for oxygen reduction reaction Path A – direct pathway, involves four-electron reduction O2 + 4 H+ + 4 e- 2 H2O ; Eo = 1.229 V Path B – indirect pathway, involves two-electron reduction followed by further two-electron reduction O2 + 2 H+ + 2 e- H2O2 ; Eo = 0.695 V H2O2 + 2 H+ + 2 e- 2 H2O ; Eo = 1.77 V Halina S. Wroblowa, Yen-Chi-Pan and Gerardo Razumney, J. Electroanal. Chem., 69 (1979) 195 3 Essential criteria for choosing an electrocatalyst for oxygen reduction Reversible Oxygen adsorption capacity Structural stability during oxygen adsorption and reduction Stability in electrolyte medium and also in suitable potential window Ability to decompose H2O2 Good conductivity Low cost 4 Why Pt ? High work function ( 4.6 eV ) Ability to catalyze the reduction of oxygen Good resistance to corrosion and dissolution High exchange current density Volcano plot J. J. Lingane, J. Electroanal. Chem., 2 (1961) 296 5 Difficulties with Pt Slow ORR due to the formation of –OH species at +0.8 V O2 + 2 Pt Pt2O2 Pt2O2 + H+ + e- Pt2-O2H Pt2-O2H Pt-OH + Pt-O Pt-OH + Pt-O + H+ + e- Pt-OH + Pt-OH Pt-OH + Pt-OH + 2 H+ + 2 e- 2 Pt + 2 H2O Scarce and expensive Cyclic voltammograms of the Pt electrode in helium-deaerated () and O2 sat. (- - -) H2SO4 Charles C. Liang and Andre L. Juliard, J. Electroanal. Chem., 9 (1965) 390 6 Objective(s) Reduction of Pt loading in the electrodes Replacement of Pt by non-noble metal based electrocatalysts Strategy Cathode (Oxygen Reduction) catalysts Pt based catalysts Non-Pt based catalysts Different sized Pt nanoparticles loaded carbon RuxSey/CDX975 catalysts Pt-M (M = Fe, Co and Cr) alloys loaded carbon Carbon supported Pd alloys; Pd-Co-M(7:2:1)/CDX975 (M = Mo and Au) Pyrolyzed Fe and Co macrocycles supported 7 on CDX975 Salient features of carbon black support (CDX975) (A) (B) Particle size: 80-100 nm 100 nm BET specific surface area is ~300 m2/g Dominant pore diameter is in the range of 2–50 nm (A) SEM image (B) TEM image (C) XRD pattern and (D) pore size distribution of the carbon black particles (CDX975) 8 Synthesis, Characterization and Oxygen Reduction Activity of Carbon Supported Pt Nanoparticles Prepared by Polyol Reduction Method 0.5 mmol Pt(acac)2 + 2 mmol 1,2-hexadecanediol + 25 ml solvent Heated to 100 oC N2 heated to 100 oC under N2 atm 0.5 mmol capping agents Thermometer heated and refluxed for different Capping agents time intervals cooled to room temperature Black suspension Heated and refluxed for 30 min Reactants: Pt(acac)2, 1,2-hexadecanediol and solvent H R H C CH2 OH OH where R = C14H29 - H2O O Pt R C H C R H H O O H C C C C +2 H H R Pt0 9 Purification 25 ml of the suspension + 100 ml of ethanol (EtOH) centrifuged for 15 min at 7200 rpm black precipitate 40 ml of hexane, 20 ml of EtOH, small amount of capping agents centrifuged for 15 min at 7200 rpm Black suspension 50 ml of EtOH centrifuged for 15 min and dried Pt nanoparticles 10 10 nm TEM images of Purified Pt nanoparticles The Pt 4f region of the XPS spectrum of the Pt nanoparticles loaded carbon support (CDX975) TEM shows the monodispersed Pt nanoparticles of size ~3.8 nm Pt 4f spectrum shows a doublet with a low-energy peak (Pt 4f7/2) and a high-energy peak (Pt 4f5/2) at 71.2 and 74.7 eV, respectively. These peaks indicated that Pt is present in metallic state, Pt(0) 20 nm 11 Reactants and conditions employed in polyol reduction method for the preparation of Pt nanoparticles of different sizes Reactants Temp (oC) and time (min) Size of Pt (nm) Pt(acac)2, 1,2-hexadecanediol, oleic acid, oleyl amine, octyl ether 290-300 30 min 1.7-1.9 (Pt1) ,, 290-300 45 min 2.3-2.6 (Pt2) ,, 290-300 60 min 3.2-3.4 (Pt3) Pt(acac)2, 1,2-hexadecanediol, nonanoic acid, nonyl amine, diphenyl ether 250-260 30 min 3.8-4.0 (Pt4) 250-260 45 min 4.6-4.9 (Pt5) 250-260 60 min 5.7-6.1 (Pt6) ,, ,, 12 Synthesis of 20 wt.% Pt/carbon black(CDX975) Carbon black (CDX975) dispersed in hexane required amount of Pt nanoparticles dispersed in hexane ultrasonic agitation 20 wt.% Pt/CDX975 Carbon black support Ultrasonication Pt sol Pt Pt Carbon black Carbon black Ultrasonic agitation solvent rich adsorption layer 13 (111) (200) (220) (311) (222) XRD patterns of the as-synthesized Pt/CDX975 catalysts (A) Pt1C (B) Pt2C (C) Pt3C (D) Pt4C (E) Pt5C and (F) Pt6C 14 A B C D E F A B C D E F TEM images of the as-synthesized Pt/CDX975 catalysts (A) Pt1C (B) Pt2C (C) Pt3C (D) Pt4C (E) Pt5C and (F) Pt6C A B C D F E EDX spectra of the as-synthesized Pt/CDX975 catalysts (A) Pt1C (B) Pt2C (C) Pt3C (D) Pt4C (E) Pt5C and (F) Pt6C 15 Electrochemical measurements Electrode fabrication Catalyst dispersed in isopropanol (5 mg/5 ml) ultrasonicated for 10 min 20 µl pipetted onto the GC disk dried in flowing Ar at room temperature 10 µl Nafion was pipetted onto the catalyst deposited GC disk dried at room temperature Electrochemical Conditions Electrolyte: O2 saturated 0.5 M H2SO4 Working electrode: Catalyst deposited GC Disk Reference electrode: Ag/AgCl, 3.5 M KCl (+0.205 V vs. NHE) Counter electrode: Pt Scan rate: 5 mV/sec 16 Linear sweep voltammograms of the as-synthesized Pt/CDX975 catalysts in Ar- and O2-saturated 0.5 M H2SO4 17 Comparison of the oxygen reduction activity of Pt nanoparticles of different sizes Catalyst Pt metal loading (wt%) Particle size (nm) Onset potential for oxygen reduction (mV vs. NHE) ORR activity at +0.7 V vs. NHE (mA cm-2) Mass activity at +0.7 V vs. NHE (A g-1) Pt1C 19.3 1.7-1.9 +935 1.9 34 Pt2C 19.5 2.3-2.6 +930 2.5 44 Pt3C 19.3 3.2-3.4 +930 4.3 76 Pt4C 19.1 3.8-4.0 +920 3.4 60 Pt5C 19.3 4.6-4.9 +890 2.8 50 Pt6C 19.6 5.7-6.1 +880 2.2 39 Commercial Pt/C (E-TEK) 19.8 3.5-3.9 +920 3.1 55 Optimum size of Pt for oxygen reduction is 3 - 4 nm 18 Synthesis, characterization and oxygen reduction activity of polyol reduced Pt alloy nanoparticles loaded carbon black Why Pt alloys are more active for oxygen reduction ? Inhibition of –OH species on Pt Shortening of Pt-Pt interatomic distance Increased d-band vacancies Order of oxide formation: Pt > Pt-Ni > Pt-Fe > Pt-Co > Pt-Cr Order of oxygen reduction activity: Pt < Pt-Ni < Pt-Fe < Pt-Co < Pt-Cr Catalyst Pt-Pt distance (Å) Pt d-band vacancies Pt Pt53Ni47 Pt51Fe49 Pt49Co51 Pt50Cr50 2.77 2.66 2.69 2.71 2.73 0.370 0.378 0.390 0.390 0.401 S. Mukerjee, S. Srinivasan, M. P. Soriaga, and J. McBreen, J. Electrochem. Soc., 142 (1995) 1409 19 PtCr/C PtNi/C PtCo/C PtFe/C Pt/C Performance of DMFC MEAs operating at 80 oC Performance of PEMFC MEAs operating at 80 oC Pt alloys offer a performance gain of 50 mV compared to Pt/C T. R. Ralph and M. P. Hogarth, Platinum Met. Rev., 46 (2002) 3 20 Proposed mechanism for oxygen reduction on Pt alloys Increase of 5d vacancies led to an increased 2 electron donation from O2 to surface Pt and weaken the O-O bond As a result, scission of the bond must occur instantaneously as electrons are back donated from 5d orbitals of Pt to 2* orbitals of the adsorbed O2 T. Toda, H. Igarashi, H. Uchida and M. Watanabe, J. Electrochem. Soc., 146 (1999) 3750 21 Synthesis of Pt-Fe alloy nanoparticles by polyol reduction method 0.5 mmol Pt(acac)2 + 0.5 mmol FeCl2 + 2 mmol 1,2-hexadecanediol + 25 ml Ph2O heated to 100 oC under N2 atm 0.5 mmol nonanoic acid and 0.5 mmol nonylamine heated to 250-260 oC and refluxed for 30 min cooled to room temperature Black suspension Similarly, Pt-Co(1:1) and Pt-Cr(1:1) alloy nanoparticles were synthesized. 22 Purification 25 ml of the suspension + 100 ml of ethanol (EtOH) centrifuged for 15 min at 7200 rpm black precipitate 40 ml of hexane, 20 ml of EtOH, small amount of capping agents centrifuged for 15 min at 7200 rpm Black suspension 50 ml of EtOH centrifuged for 15 min and dried Pt alloy nanoparticles 23 B A C TEM images of as-synthesized (A) Pt-Fe (B) Pt-Co and (C) Pt-Cr nanoparticles A B C TEM images of carbon supported Pt alloy catalysts: (A) Pt-Fe(1:1)/CDX975 (B) Pt-Co(1:1)/CDX975 and (C) Pt-Cr(1:1)/CDX975 24 A B C EDX spectra of the (a) Pt-Cr(1:1)/CDX975 (b) Pt-Co(1:1)/CDX975 and (c) Pt-Fe(1:1)/CDX975 25 (a) Commercial Pt/C (b) Pt-Cr(1:1)/CDX975 (c) Pt-Co(1:1)/CDX975 (d) Pt-Fe(1:1)/CDX975 Structural parameters Catalyst Maximum 2θ of Pt(111) (˚) Lattice parameter afcc (Å) Pt-Cr(1:1)/CDX975 40.48 3.857 Pt-Co(1:1)/CDX975 40.52 3.852 Pt-Fe(1:1)/CDX975 40.58 3.848 Pt/C (E-TEK) 39.8 3.920 XRD patterns of the catalysts The diffraction peaks are characteristic of a face-centered cubic (FCC) lattice, but the reflections are shifted to higher angles in Pt alloys compared to that of Pt metal, indicating a contraction of the lattice due to alloy formation. 26 Electrochemical measurements Electrode fabrication Catalyst dispersed in isopropanol (5 mg/5 ml) ultrasonicated for 10 min 20 µl pipetted onto the GC disk dried in flowing Ar at room temperature 10 µl Nafion was pipetted onto the catalyst deposited GC disk dried at room temperature Electrochemical Conditions Electrolyte: O2 saturated 0.5 M H2SO4 Working electrode: Catalyst deposited GC Disk Reference electrode: Ag/AgCl, 3.5 M KCl (+0.205 V vs. NHE) Counter electrode: Pt Scan rate: 5 mV/sec 27 Cyclic voltammograms of the carbon supported Pt alloys and commercial Pt/C (E-TEK) catalysts in Ar-saturated 0.5 M H2SO4 Linear sweep voltammograms of the carbon supported Pt alloys and commercial Pt/C catalysts in Ar- and O2-saturated 0.5 M H2SO4 High ORR activity of Pt alloy catalysts is attributed to the inhibition of –OH species on Pt by the alloying element 28 Comparison of ORR activities of Pt alloys and commercial Pt/C catalysts Particle size (nm) Onset potential for oxygen reduction (mV vs. NHE) ORR activity at +0.7 V vs NHE (mA/cm2) Catalyst Metal loading (wt%) 20% Pt-Cr(1:1)/CDX975 Pt – 15.3; Cr – 4.1 5.1-5.3 +990 5.2 20% Pt-Co(1:1)/CDX975 Pt – 15.1; Co – 4.5 4.9-5.2 +970 5.0 20% Pt-Fe(1:1)/CDX975 Pt – 15.4; Fe – 4.4 6.4-6.8 +960 4.2 20% Pt/C (E-TEK) Pt – 19.8 3.5-3.9 +925 3.1 Order of oxygen reduction activity: Pt/C (E-TEK) < Pt-Fe(1:1)/CDX975 < Pt-Co(1:1)/CDX975 ≈ Pt-Cr(1:1)/CDX975 29 10% 22% 24% 33% Current density-time plots of as-synthesized Pt-M(1:1)/CDX975 and commercial Pt/C catalysts at +0.7 V vs. NHE in O2-saturated 0.5 M H2SO4 30 Synthesis, characterization and oxygen reduction activity of carbon supported Pd and Pd alloy catalysts prepared by Reverse Microemulsion Method Why Pd alloys are more active than metal alone for oxygen reduction? (1) Induced change in the density of states (DOS) at the Fermi level of Pd sites by alloy formation. Ota’s group considered that the decreased DOS induced by the electron transfer from Co, Ni, or Cr to Pd may weaken the chemisorption bonds between Pd and reactants such as O2, O/OH, O2−, and H2O2, reducing their blocking effect in the O2 reduction process. As a result, the ORR kinetics may be enhanced. For example, an alloyed Pd showed a reduced ORR overpotential by 50mV at 0.2 mA cm−2 compared to that catalyzed by pure Pd. [K. Lee, O. Savadogo, A. Ishihara, S. Mitsushima, N. Kamiya, K.-I. Ota, J. Electrochem. Soc. 153 (1) (2006) A20.] (2) Induced change in ORR Gibbs free energy. Wang and Balbuena explained that if a catalyst consists of two metals, one with a low occupancy of d-orbitals (such as Co, Ni, Cr, or V) and the other with fully occupied d-orbitals (such as Pd, Au, and Ag), the d-orbital coupling effect between them can significantly decrease the Gibbs free energy of the electron transfer steps in ORR, resulting in an enhancement in ORR kinetics. [Y.X. Wang, P.B. Balbuena, J. Phys. Chem. B 109 (2005) 18902.] 31 Comparison of steady-state polarization curves of the various heat treated carbon supported Pd alloy catalysts for ORR in single-cell PEMFC with that of the commercial (JM) Pt catalyst The samples with Pd:Co:Mo/Au = 70:20:10 exhibit higher catalytic activity than the Pd:Co = 80:20 sample (without Mo/Au) suggesting that the incorporation of Mo/Au improves the ORR activity significantly. The Pd-Co-Mo/C catalyst heat treated at 500 °C (24 nm) exhibits better performance with lower polarization loss than the commercial Pt (3.8 nm) and PdCo-Au catalysts (13 nm) at the same loading. Pd-Co-Mo/C and Pd-Co-Au/C shows an open circuit voltage of 0.9 V, which is close to that found with the commercial (JM) Pt catalyst. 32 Synthesis of 20 wt% Pd-Co-Mo(7:2:1)/CDX975 Step 1 H2PdCl4 + CoCl2 + MoCl5 + Triton-X-100 + 2-propanol + cyclohexane stirred for 30 min followed by ultrasonication for 15 min Microemulsion 1 Step 2 Hydrazine + Triton-X-100 + 2-propanol + cyclohexane stirred for 30 min followed by ultrasonication for 15 min Microemulsion 2 33 Microemulsion 1 + Microemulsion 2 ultrasonication for 1 hr carbon black (CDX975) stirred for 2 hr filtered and washed with acetone and water dried for 2 hr heat treatment under Ar-H2 atm for 1 hr at dfiferent temp 20% Pd-Co-Mo(7:2:1)/CDX975 Similarly, 20% Pd/CDX975 and 20% Pd-Co-Au(7:2:1)/CDX975 catalysts were prepared. 34 (a) Pd/CDX975 (b) as-syn Pd-Co-Mo(7:2:1)/CDX975 (c) Pd-Co-Mo(7:2:1)/CDX975 at 700 ˚C (d) Pd-Co-Mo(7:2:1)/CDX975 at 800 ˚C (e) Pd-Co-Mo(7:2:1)/CDX975 at 900 ˚C (a) Pd/CDX975 (b) as-syn Pd-Co-Au(7:2:1)/CDX975 (c) Pd-Co-Au(7:2:1)/CDX975 at 700 ˚C (d) Pd-Co-Au(7:2:1)/CDX975 at 800 ˚C (e) Pd-Co-Au(7:2:1)/CDX975 at 900 ˚C XRD patterns of the carbon supported Pd and Pd alloy catalysts The diffraction peaks are characteristic of a face-centered cubic (FCC) lattice, but the reflections are shifted to higher angles compared to that of Pd metal, indicating a contraction of the lattice due to alloy formation. 35 Structural parameters of Pd/CDX975 and Pd-Co-M/CDX975 (M =Mo and Au) catalysts Catalyst Maximum 2θ of Pt(111) (˚) Lattice parameter afcc Å) Crystallite size (nm) Pd/CDX975 As-synthesized Pd-Co-Mo(7:2:1)/CDX975 Pd-Co-Mo(7:2:1)/CDX975 at 700 ˚C Pd-Co-Mo(7:2:1)/CDX975 at 800 ˚C Pd-Co-Mo(7:2:1)/CDX975 at 900 ˚C 40.03 40.04 40.46 40.59 40.68 3.898 3.897 3.858 3.847 3.838 1.2 1.6 7.1 9.4 13.5 As-synthesized Pd-Co-Au(7:2:1)/CDX975 Pd-Co-Au(7:2:1)/CDX975 at 700 ˚C Pd-Co-Au(7:2:1)/CDX975 at 800 ˚C Pd-Co-Au(7:2:1)/CDX975 at 900 ˚C 40.05 40.51 40.67 40.84 3.896 3.854 3.839 3.824 2.1 6.3 8.7 10.4 Debye-Scherrer’s equation Crystallite size, 0.89 L 1 2 cos where λ is the wavelength of the X-ray (1.5406 Å), θ is the angle at the position of the peak maximum and β1/2 is the FWHM (in radians). 36 TEM image and EDX spectrum of the 20% Pd-Co-Mo/CDX975 (700) TEM image and EDX spectrum of the 20% Pd-Co-Au/CDX975 (800) 37 Electrochemical measurements Electrode fabrication Catalyst dispersed in isopropanol (5 mg/5 ml) ultrasonicated for 10 min 20 µl pipetted onto the GC disk dried in flowing Ar at room temperature 10 µl Nafion was pipetted onto the catalyst deposited GC disk dried at room temperature Electrochemical Conditions Electrolyte: O2 saturated 0.5 M H2SO4 Working electrode: Catalyst deposited GC Disk Reference electrode: Ag/AgCl, 3.5 M KCl (+0.205 V vs. NHE) Counter electrode: Pt Scan rate: 5 mV/sec 38 Cyclic voltammograms of the carbon supported Pd and Pd alloy catalysts in 0.5 M H2SO4 39 Linear sweep voltammograms of the carbon supported Pd and Pd alloy catalysts in Ar- and O2-saturated 0.5 M H2SO4 40 Comparison of ORR activities of Pd based catalysts with commercial Pt/C EDX composition Pd:Co:M (M = Mo, Au) Onset potential for oxygen reduction (mV vs. NHE) ORR activity at +0.7 V vs NHE (mA/cm2) 20% Pd/CDX975 100: - : - +860 1.6 20% Pd-Co-Mo(7:2:1)/CDX975 at 700˚C 77.7:12.3:10.0 +925 4.1 20% Pd-Co-Mo(7:2:1)/CDX975 at 800˚C 78.3:12.6:9.1 +905 3.0 20% Pd-Co-Mo(7:2:1)/CDX975 at 900˚C 78.7:12.5:8.8 +870 2.6 20% Pd-Co-Au(7:2:1)/CDX975 at 700˚C 70.2:11.2:18.6 +895 3.3 20% Pd-Co-Au(7:2:1)/CDX975 at 800˚C 71.3:11.6:17.1 +905 3.9 20% Pd-Co-Au(7:2:1)/CDX975 at 900˚C 71.8:11.3:16.9 +905 2.9 Commercial 20% Pt/C (E-TEK) --- +920 3.1 Catalyst 41 14% 4% 2% 17% 23% 12% 22% 22% Current density-time plots of carbon supported Pd and Pd alloy catalysts at +0.7 V vs. NHE in O2-saturated 0.5 M H2SO4 42 RuxSey/C catalysts for Oxygen Reduction – A Reverse Microemulsion Method of Fabrication of Electrode Material Why RuxSey catalysts? MoxRuySz, RhxRuySz, RexRuySz, MoxRuySez • Ru O X = S, Se, Te MoxRhySz, MoxOsySz, WxRuySz RuxSy, RuxSey, RuxTey O2 + 4 H++ 4 e- 2 H2O Carbon supported catalysts Crystal structure of RuxXy catalysts Characteristic features Metal cluster - reservoir of electronic charge carriers Capacity to provide neighbouring binding sites for reactants and intermediates Volume and bond distances are flexible Good conductivity N. Alonso Vante, W. Jaegerman, H. Tributsch, W. Honle and K. Yvon, J. Am. Chem. Soc., 43 109 (1987) 3251 Influence of selenium High current densities Inhibition of formation of Ru oxides Lower amount of H2O2 production (< 3 vol%) Tafel plots for the ORR, as obtained from RDE experiments in O2 saturated 0.5 M H2SO4 Enhanced stability towards electrochemical oxidation Ru A: 0 Mol% Se B: 10.01 Mol% Se C: 14.3 Mol% Se RuOx XRD-spectra of catalysts prepared with different amounts of selenium A: 14.3 mol% Se B: 5.27 mol% Se C: 0 mol% Se D: metallic Ru Tafel slopes and over potentials for Ru-based cluster catalysts with different Se contents Mol% Se Tafel slope /mV dec-1 Overpotential // mV at 10 A cm-2 14.3 10.0 5.3 1.8 0 96.6 101.5 120.0 128.4 146.2 330.0 322.5 317.5 327.0 342.5 Potential dependent hydrogen peroxide production of Ru based cluster catalysts with different selenium content M. Bron, P. Bogdanoff, S. Fiechter, I. Dorbandt, M. Hilgendorff, H. Schulenburg and H. Tributch, J. Electroanal. Chem., 500 (2001) 510 44 Preparation methods for transition metal chalcogenide catalysts for oxygen reduction Method Starting chemicals Operating conditions Typical catalysts Particle size (nm) Reference Low temp pyrolysis method Ru3(CO)12, chalcogen (X) 300 ˚C, sealed glass ampoule RuxXyOz ~5 S. Duron et al., 2000 Colloidal method RuCl3, Se THF solvent with N(C8H17)4BEt3 RuxSeyOz 3-4 H. Tributsch et al., 2001 Impregnation method Ru3(CO)12, H2SeO3 300 ˚C, aq. Solvent RuxSey 4-6 M. Hilgendorff et al., 2003 Aqueous medium method RuCl3, SeO2, NaBH4 80 ˚C, aq. Solvent RuxSe ~4 A. Stephen, US patent 2004 Pyrolysis method Ru4Se2(CO)11 220 ˚C, He atm Ru2Se clusters ~2 W. Vogel et al., 2007 Alloying method RuCl3, SeO2 200 ˚C, H2 atm RuxSey 4-7 L. Colmenares et al., 2007 45 Synthesis of 20 wt% RuxSey/CDX975 catalysts Step 1 RuCl3.xH2O + H2SeO3 + AOT + water + heptane stirring followed by ultrasonication for 20 min Microemulsion 1 Step 2 NaBH4 + AOT + water + heptane stirring followed by ultrasonication for 20 min Microemulsion 2 46 Microemulsion 1 + Microemulsion 2 ultrasonication for 1 hr carbon black (CDX975) stirred for 2 hr filtered and washed with acetone and water dried for 2 hr 20% RuxSey/CDX975 where x = 1 and y = 0-1 47 XRD patterns of as-synthesized RuxSey/CDX975 catalysts; (a) Ru/CDX975 (b) Ru1Se0.2/CDX975 (c) Ru1Se0.4/CDX975 (d) Ru1Se0.6/CDX975 (e) Ru1Se0.8/CDX975 and (f) Ru1Se1/CDX975 (inset shows the slow scan XRD spectra for the (110) peak of RuxSey/CDX975 catalysts) As-synthesized RuxSey/CDX975 catalysts show the peaks at 2θ values around 38˚, 42˚, 44˚, 58˚, 69˚, 78˚ and 85˚ corresponding to the (100), (002), (101), (102), (110), (103) and (112) planes of 48 ruthenium respectively. These characteristic peaks can be assigned to hcp ruthenium. Structural parameters Se content C (Å) a (Å) 0.866 a2c (Å3) Ru/CDX975 4.27 2.713 27.21732 Ru1Se0.2/CDX975 4.263 2.708 27.07264 Ru1Se0.4/CDX975 4.257 2.700 26.87504 Ru1Se0.6/CDX975 4.251 2.697 26.77755 Ru1Se0.8/CDX975 4.245 2.694 26.6803 Ru1Se1/CDX975 4.239 2.687 26.50432 Variation of lattice parameters with Se content Both the lattice parameters (a, c) and the cell volume of RuxSey decrease linearly with increasing Se content (obeying Vegard’s law) indicate the formation of RuSe solid solution. 49 a b 1 µm 5 µm (a) SEM image (inset shows the high magnification image) and (b) EDX spectrum of Ru1Se0.6/CDX975 50 TEM images of (a) Ru1Se0.6/CDX975 at low magnification (b) Ru1Se0.6/CDX975 at high magnification (c) histogram of Ru1Se0.6 particles on CDX975 and 51 (d) commercial Pt/C (E-TEK) Electrochemical measurements Electrode fabrication 5 mg of catalyst + 0.5 ml of 5wt% Nafion + 0.5 ml of isopropanol ultrasonicated for 20 min 5 µl pipetted onto the GC disk dried in flowing Ar at room temperature Electrochemical Conditions Electrolyte: O2 saturated 0.5 M H2SO4 Working electrode: Catalyst deposited GC Disk Reference electrode: Ag/AgCl, 3.5 M KCl (+0.205 V vs. NHE) Counter electrode: Pt Scan rate: 5 mV/sec 52 LSVs of O2 reduction on 20 wt% RuxSey/CDX975 and commercial Pt/C (E-TEK) catalysts in 0.5 H2SO4; Scan rate – 5 mV sec-1 (Empty and full symbols corresponding to the LSVs in Ar- and O2- saturated 0.5 M H2SO4 respectively) CVs of (■) Ru/CDX975 and (●) Ru1Se0.6/CDX975 catalysts in Ar-saturated 0.5 H2SO4; Scan rate – 20 mV sec-1 ORR activity exhibits a maximum for the Ru1Se0.6/C catalyst ORR activity is due to stabilization of Ru active sites by Se against blocking as a result of (hydr)oxide formation. 53 Elemental composition, Se/Ru atomic ratio, crystallite size, onset potential for oxygen reduction and ORR activities of 20 wt% RuxSey/CDX975 (x = 1 and y = 0-1) and commercial 20 wt% Pt/C (E-TEK) catalysts Catalyst Elemental composition by EDX Se/Ru atomic ratio Crystallite size from XRD (nm) Onset potential (mV) for oxygen reduction ORR activity at +0.65 V vs. NHE (mA/cm2) Ru/CDX975 Ru1Se0.2/CDX975 Ru1Se0.4/CDX975 Ru1Se0.6/CDX975 Ru1Se0.8/CDX975 Ru1Se1/CDX975 Pt/C (E-TEK) 100:87.7:12.3 76.6:23.4 68.5:31.5 62.2:37.8 56.2:43.8 - 0.0 0.18 0.38 0.59 0.78 1.00 - 3.0 3.0 3.1 3.1 3.1 3.1 +850 +875 +890 +905 +885 +870 +930 1.3 2.1 3.0 4.2 1.6 1.4 4.0 ORR activity exhibits a maximum for the Ru1Se0.6/CDX975 catalyst ORR activity of Ru1Se0.6/CDX975 was comparable with that of Pt/C (E-TEK) catalyst Se/Ru atomic ratio vs. ORR current density of as-synthesized RuxSey/CDX975 catalysts 54 Catalyst Degradation of activity (%) Ru/CDX975 Ru1Se0.2/CDX975 Ru1Se0.4/CDX975 Ru1Se0.6/CDX975 Ru1Se0.8/CDX975 Ru1Se1/CDX975 Pt/C (E-TEK) 80 33 14 2 48 50 23 Current density vs. time curves of as-synthesized 20 wt% RuxSey/CDX975 catalysts; (a) Ru/CDX975 (b) Ru1Se0.2/CDX975 (c) Ru1Se0.4/CDX975 (d) Ru1Se0.6/CDX975 (e) Ru1Se0.8/CDX975 (f) Ru1Se1/CDX975 and (g) commercial Pt/C (E-TEK) measured in oxygen saturated 0.5 M H2SO4 at +0.65 V vs. NHE Order of stability: Ru/CDX975 < Ru1Se1/CDX975 < Ru1Se0.8/CDX975 < Ru1Se0.2/CDX975 < Pt/C (E-TEK) 55 < Ru1Se0.4/CDX975 < Ru1Se0.6/CDX975 MN4Cx clusters (M = Fe and Co) – A potential oxygen reduction electrodes for PEMFC applications Transition metal macrocycles Square planar complexes with the central metal atom symmetrically surrounded by four nitrogen atoms Structural analogues of metabolic systems Delocalization of ‘’ electrons – high conductivity Stability in both acidic and basic media 56 Why Fe- and Co- containing macrocycles appear to be the best for oxygen reduction ? ORR activity (V vs. SCE) Volcano plot . .. FeTPP Oxygen reduction activities of various catalysts catalyst Mass activity at 0.7 V vs. NHE (mA/mg) FeTPP CoTPP FePc CoPc RuPc RuTPP MnTPP OsTPP CrTPP CoTAA 0.06 0.08 0.07 0.05 0.04 0.02 0.01 0.007 0.007 0.005 CoOEP CoTPP Redox potential (V vs. SCE) Jose H. Zagal, Coord. Chem. Rev., 119 (1992) 89 57 Adverse effect of H2O2 on catalytic activity x x + H2O2, + O2 M -x x M M -M x Mechanism of the disintegration of metal macrocycle K. Weisener, Electrochimica Acta, 31 (1986) 1073 58 How to increase the oxygen reduction activity ? Pyrolysis of the carbon supported metal macrocycles Remarkable oxygen reduction activities of pyrolyzed Fe- and Co- based catalysts catalyst Metal loading (wt%) FeTPP/Vulcan XC72R heat treated at 600oC CoTPP/Vulcan XC72R heat treated at 600oC FePc/Vulcan XC72R heat treated at 500oC CoPc/Vulcan XC72R heat treated at 600oC FeTMPP-Cl/BP heat treated at 800oC FeTPP/CoTPP heat treated at 600oC 2.0 2.0 2.0 1.9 2.0 2.0 ORR activity at 0.7 V vs. NHE 2 (mA/cm ) (mA/mg) 3.9 3.1 4.0 3.1 5.1 3.0 102 (0.06) 98 (0.08) 78 (0.07) 58 (0.05) 127 (0.11) 69 (----) # The values shown in bracket are the activities of non-heat treated catalysts Visualization of the reaction of the porphyrin with the carbon during heat treatment Active species for oxygen reduction --- MN4Cx (M = Fe, Co) 59 Criteria for oxygen reduction by MN4 Orbital wave functions have to be of same symmetry Orbital energies have to be matched for suitable activation - Reduction Electron transfer should be facile 3u* 1g* 2p 2p 1u 3g 2u* 2s 2s 2g Molecular Orbital diagram of O2 molecule Oxygen reduction takes place by the transfer of electron from HOMO of MN4 to 60 the anti-bonding * of O2 molecule Methodology Single point energy – DFT calculations by Gaussian98 B3LYP LANL2DZ – Basis set Model systems : MN4 (M = Fe, Co) and O2 N O M N N N Fe-N distance: 2.00 Å Co-N distance: 2.01 Å N-M-N : 109o47' O O-O distance : 1.26 Å 61 Percentage atomic orbital contributions to HOMO and LUMO of MN4 and O2 Model system FeN4 CoN4 Model system O2 s M = Fe, Co p d s p HOMO: -7.56 0.0 0.0 30.8 0.0 69.1 LUMO: -7.00 0.0 0.0 0.0 0.0 100.0 HOMO: -7.78 2.3 0.0 21.1 1.1 75.4 LUMO: -7.01 0.0 1.6 3.2 1.6 93.4 E (eV) E (eV) N O s O p s p HOMO: -8.18 (* level) 0.0 50.0 0.0 50.0 LUMO: +6.41 28.3 21.6 28.3 21.6 Suitable energies of HOMO of MN4 and * orbital of O2 causes the facile reduction of oxygen 62 Electron density maps HOMO of FeN4 HOMO of CoN4 * orbital of O2 63 Energy level diagram Mode of activation of O2 by FeN4 Presence of ‘N’ in MN4 plays an important role in attaining directional wave functions there by leading to facile electron transfer. 64 Synthesis of Iron Tetraphenylporphyrin (FeTPP) 40 ml anhydrous pyridine + 5 ml triethylamine + 0.5 ml TBP 10-2 mol FeCl2 5 x 10-3 mol H2TPP refluxed under Ar for 2 hr filtered and dried at 75 oC FeTPP 65 Preparation FeTPP/CDX975 0.17 g FeTPP + 60 ml anhydrous Pyridine 0.54 g CDX 975 refluxed overnight under Ar filtered and washed with H2O dried at 75 C FeTPP/CDX975 - The prepared catalyst was made into fine powder and heat treated at different temperatures ranging from 100 – 900 oC 66 Synthesis of Iron Phthalocyanine (FePc) 2.54 g FeCl2 10.2 g Phthalonitrile 5 ml TBP 100 ml ethylene glycol refluxed for 2 hr under Ar filtered and dried at 75 oC 150 ml methanol + 8 ml HCOOH refluxed for 30 min under Ar dried at 75 oC FePc 67 Preparation FePc/CDX975 0.12 g FePc + 60 ml anhydrous Pyridine 0.5 g CDX 975 refluxed for 8 hr under Ar filtered and washed with H2O dried at 75C FePc/CDX975 - The prepared catalyst was made into fine powder and heat treated at different temperatures ranging from 100 – 900 oC 68 Electrochemical measurements Electrode fabrication 16 mg catalyst + 0.4 ml of H2O + 0.4 ml of 5 % Nafion Ultrasonicated for 10 min 10 µl pipetted onto the GC disk Dried in air at 75 °C Electrochemical Conditions Electrolyte: O2 saturated 0.5 M H2SO4 Working electrode: Catalyst deposited on GC Reference electrode: Ag/AgCl electrode Counter electrode: Pt Scan rate: 10 mV/sec 69 Heat treatment temp (oC) Wt % of ‘Fe’ by redox titration method Wt % of ‘N’ by Kjeldahl method Oxygen reduction activity at +0.7 V vs NHE (mA/cm2) untreated 1.96 2.3 0.0 100 NM 2.2 0.0 200 NM 2.14 0.0 300 NM 2.1 0.08 400 NM 1.87 1.1 500 NM 1.74 1.8 600 1.97 1.7 3.81 700 NM 1.65 2.72 800 NM 1.3 1.6 900 NM 1.04 1.2 (NM = not measured) heat-treated FeTPP/CDX975 at 600 oC showing higher activity 70 Heat treatment temp (oC) Wt % of ‘Fe’ by redox titration method Wt % of ‘N’ by Kjeldahl method Oxygen reduction activity at +0.7 V vs NHE (mA/cm2) untreated 1.86 1.94 0.0 100 NM 1.62 0.0 200 NM 1.58 0.0 300 NM 1.5 0.13 400 NM 1.48 0.4 500 NM 1.4 2.4 600 1.85 1.2 2.2 700 NM 1.1 0.44 800 NM 0.4 0.31 900 NM 0.18 0.18 (NM = not measured) heat-treated FePc/CDX975 at 500 oC showing higher activity 71 Synthesis of Iron and Cobalt Tetramethoxyphenylporphyrins 56 ml of N,N'-dimethylformamide refluxed under Ar 0.67 g H2TMPP 0.22 g metal salt (10% extra) refluxed under Ar for 2 hr cooled in an ice bath and a portion of ice-water mixture was added filtered and dried at 110 oC M-TMPP (M = Fe and Co) Finally it was purified by column chromatography using benzene-chloroform (1:1) as the eluant. Elemental composition of the synthesized complexes Complex FeTMPPCl (C48H36N4O4FeCl) CoTMPP (C48H36N4O4Co) Elemental analysis calculated (wt%) C, 66.95; H, 4.18; N, 6.51; Fe, 6.49 C, 72.82; H, 4.55; N, 7.08; Co, 7.46 found (wt%) C, 66.81; H, 4.07; N, 6.43; Fe, 6.57 C, 71.90; H, 4.41; N, 6.97; Co, 7.49 72 Modification of carbon support (CDX975) with HNO3 1 g of carbon, CDX975 + 20 ml of 70 wt % HNO3 refluxed for 7 hr filtered, washed with deionized water and methanol dried at 70 °C CDX975(T) Preparation M-TMPP (M = Fe & Co)/CDX975(UT&T) and MN4Cx catalysts M-TMPP (M = Fe and Co) + Acetone required amount of CDX 975(UT & T) ultrasonicated for 30 min solvent removal under vacuum M-TMPP/CDX975(UT &T) heat treated at 800 °C in Ar atm for 2 hr MN4Cx (M = Fe & Co) (Metal loading: 2 wt%) The untreated M-TMPP adsorbed on as-received (CDX1) and oxidized (CDX2) carbon were designated as CDX1-MTMPP(UT) and CDX2-MTMPP(UT) respectively. The heat treated M-TMPP adsorbed on as-received (CDX1) and oxidized (CDX2) carbon 73 were designated as CDX1-MTMPP(HT) and CDX2-MTMPP(HT) respectively. Here ‘M’ represents Fe and Co. Electrochemical measurements Electrode fabrication Electrochemical Conditions 16 mg catalyst + 0.4 ml of H2O + 0.4 ml of 5 % Nafion Electrolyte: O2 saturated 0.5 M H2SO4 Working electrode: Catalyst deposited on GC Ultrasonicated for 10 min Reference electrode: Ag/AgCl, 3.5 M KCl (+0.205 V vs. NHE) 10 µl pipetted onto the GC disk Counter electrode: Pt Dried in air at 75 °C Scan rate: 10 mV/sec Single cell PEMFC measurements Gas diffusion electrodes were prepared by a combined filtration/brushing procedure. A homogeneous catalyst suspension consisted of 12.9 mg of catalyst, 0.5 ml of H2O and 0.3 ml of 5 wt % Nafion solution blended ultrasonically for 1 h was applied on the teflonized carbon cloth substrate by layer wise. Both anode and cathode electrodes were then placed in a vacuum oven at 75 C for 1 h. The anode (20 wt% Pt/C from E-TEK) consists of 0.4 mg Pt/cm2. The cathode (prepared Fe and Co catalyst) consists of 0.2 mg metal/cm2. The membrane-electrode assembly (MEA) was obtained by sandwiching the Nafion115 membrane between the cathode and anode by hot pressing at 140 °C and 50 kg cm−2 for 1 min. The fuel cell testing was carried out at an operating temperature of 80 °C and 1 atm 74 pressure with humidified hydrogen and oxygen gas reactants. CDX1 CDX2 CVs of untreated and treated CDX975 in Ar- saturated 0.5 M H2SO4 As-received carbon (CDX1) and oxidized carbon (CDX2) exhibit well-defined redox peaks at ~0.55 V vs. NHE which are corresponding to quinone/hydroquinone groups on the carbon surface. 75 Linear sweep voltammograms (LSVs) of untreated and heat treated Fe(III)TMPP-Cl supported on as-received and oxidized carbon catalysts in Ar- and O2 -saturated 0.5 M H2SO4 76 Linear sweep voltammograms (LSVs) of untreated and heat treated CoTMPP supported on asreceived and oxidized carbon catalysts in Ar- and O2 - saturated 0.5 M H2SO4. 77 B A 100 nm 100 nm D C 100 nm 100 nm TEM images of (A) CDX1-FeTMPPCl(HT), (B) CDX2-FeTMPPCl(HT), (C) CDX1-CoTMPP(HT) and (D) CDX2-CoTMPP(HT) 78 Particle size of catalysts analyzed in TEM Catalyst CDX1-FeTMPPCl(HT) CDX2-FeTMPPCl(HT) CDX1-CoTMPP(HT) CDX2-CoTMPP(HT) Particle size (nm) 25-37 8-15 35-50 10-18 Higher dispersion of catalyst particles on oxidized carbon (CDX2) compared to the un-oxidized carbon (CDX1). Estimated metal loading, onset potential for oxygen reduction and oxygen reduction activities of Fe- and Co-based catalysts as well as commercial Pt catalysts Catalyst CDX1-FeTMPPCl(UT) CDX2-FeTMPPCl(UT) CDX1-FeTMPPCl(HT) CDX2-FeTMPPCl(HT) CDX1-CoTMPP(UT) CDX2-CoTMPP(UT) CDX1-CoTMPP(HT) CDX2-CoTMPP(HT) Pt/C (E-TEK) Metal (Fe or Co) loading (wt%) Onset potential for oxygen reduction (mV) vs. NHE ORR activity at +0.7 V vs. NHE (mA cm-2) 2.01 2.03 1.96 1.97 1.98 1.97 1.89 1.93 2.07 +810 +830 +840 +870 +740 +760 +795 +860 +910 0.2 0.35 4.2 4.9 0.16 0.24 3.2 4.5 4.9 (UT = untreated and HT = heat-treated) By increasing the number of surface oxygen groups (quinones) on the carbon support, 79 the dispersion of the catalysts, as well as their ultimate performance, is increased. Δ CDX1-FeTMPPCl(HT) -- 40% ▲CDX2- FeTMPPCl(HT) – 33% □ CDX1-CoTMPP(HT) ---- 50% ■CDX2-CoTMPP(HT) ----- 30% Pt/C (E-TEK) ------ ------- 30% Current density vs. time curves of catalysts in oxygen saturated 0.5 M H2SO4 at +0.7 V vs. NHE Δ CDX1-FeTMPPCl(HT) ▲CDX2- FeTMPPCl(HT) □ CDX1-CoTMPP(HT) ■ CDX2-CoTMPP(HT) Pt/C (E-TEK) H2/O2 PEM fuel cell polarization curves with catalysts for oxygen reduction at 80 C Single-cell PEMFC performance of Fe- and Co-based catalysts as well as Pt catalysts Catalyst Performance at +0.7 V vs. NHE (mA cm-2) CDX1-FeTMPPCl(HT) CDX2-FeTMPPCl(HT) CDX1-CoTMPP(HT) CDX2-CoTMPP(HT) Pt/Vulcan XC72R (E-TEK) 125 171 82 104 180 80 Salient features: In the case of Untreated and heat treated catalysts, the ORR activity was found to be, CDX1-FeTMPPCl(UT)<CDX2-FeTMPPCl(UT)<CDX1-FeTMPPCl(HT)<CDX2-FeTMPPCl(HT) CDX1-CoTMPP(UT)<CDX2-CoTMPP(UT)<CDX1-CoTMPP(HT)<CDX2-CoTMPP(HT) It implies that (i) the active species, MN4Cx species generated by the heat treatment increases the ORR activity and stability and (ii) The increased number of surface oxygen functionalities introduced by nitric acid treatment improve the ORR performance as well as stability under the experimental conditions. TEM measurements show that the increased dispersion of active species in the case of oxidized carbon (CDX2) compared to the as-received carbon (CDX1). EDX confirms the presence of metal (Fe and/or cobalt), nitrogen and carbon in the prepared electrocatalysts. In both Fe and Co based catalysts, there is approximately +30 mV or more positive shift of onset potential for oxygen reduction in the case of oxidized carbon containing electrocatalysts compared to that of the as-received carbon containing electrocatalysts. It implies that the overpotential for oxygen reduction was reduced by means of oxidized carbon support. The increased order of ORR activity as well as stability of heat treated catalysts and commercial Pt/C was found to be, CDX1-CoTMPP(HT)<CDX2-CoTMPP(HT)≈CDX1-FeTMPPCl(HT)<CDX2-FeTMPPCl(HT) ≈commercial Pt/C. 81 Conclusion 82 Scanning electrochemical microscopy (SECM) was based on simple thermodynamic principles that involve the pairing of a good oxygen-bond cleaving metal with a good oxygen-reducing metal. SECM images of oxygen reduction activity measured on a binary Pd-Ti array in 0.5 M H2SO4 by scanning a 25 µm tip generating oxygen above an array of different compositions at different potentials. Tip-substrate distance = 30 µm, tip current = -171 nA, and scan rate = 50 µm each 0.2 s. Potentials are vs. the hydrogen reference electrode. The image is a color-map graph of substrate current vs. tip position (X, Y). This screening technique is based upon producing an array of bimetallic or trimetallic catalyst spots with different compositions on a glassy carbon (GC) support. A small ultramicroelectrode tip is used to generate oxygen at a constant current as the tip is scanned above the array of spots, with the GC held at different potentials, so that each spot registers a current proportional to the rate of oxygen reduction at that location (GC, which is a poor oxygen reduction catalyst, does not produce a significant response at these 83 potentials). Why Pd or Pt alloys are more active than metal alone for oxygen reduction? (1) Induced change in the density of states (DOS) at the Fermi level of Pd sites by alloy formation. Ota’s group considered that the decreased DOS induced by the electron transfer from Co, Ni, or Cr to Pd may weaken the chemisorption bonds between Pd and reactants such as O2, O/OH, O2−, and H2O2, reducing their blocking effect in theO2 reduction process. As a result, the ORR kinetics may be enhanced. For example, an alloyed Pd showed a reduced ORR overpotential by ∼50mV at 0.2mAcm−2 compared to that catalyzed by pure Pd. [K. Lee, O. Savadogo, A. Ishihara, S. Mitsushima, N. Kamiya, K.-I. Ota, J. Electrochem. Soc. 153 (1) (2006) A20.] (2) Induced change in ORR Gibbs free energy. Wang and Balbuena explained that if a catalyst consists of two metals, one with a low occupancy of d-orbitals (such as Co, Ni, Cr, or V) and the other with fully occupied d-orbitals (such as Pd, Au, and Ag), the d-orbital coupling effect between them can significantly decrease the Gibbs free energy of the electron transfer steps in ORR, resulting in an enhancement in ORR kinetics. [Y.X. Wang, P.B. Balbuena, J. Phys. Chem. B 109 (2005) 18902.] (3) Pd lattice compression induced by alloy formation. A metal d-band center can be altered by orbital overlap. The formation of the alloy can induce Pd lattice compression (or reduction of bond lengths between metals) through the modification of the electronic structure and orbital overlap. This will cause the shift of the d-band center, resulting in a change in the surface activity of Pd sites. The density functional theory calculations made by Norskov’s group confirmed that the compression of a Pd lattice in alloys could downshift the d-band center energy. The Pd lattice compression can enhance the catalyzed ORR. [B. Hammer, J.K. Norskov, Adv. Catal. 45 (2000) 71.] 84 Typical polarization curve EOC 1.21 V Activation losses Ohmic losses Mass transport losses Cell E (i) (ii) (iii) Current Typical polarization curve for a fuel cell: voltage drops due to: (i) surface reaction kinetics; (ii) electrolyte resistance and (iii) reactant/product diffusion rates Activation losses – Energy barrier associated with catalytic reactions at the electrodes Ohmic losses - ionic resistance in the electrolyte and electrodes electronic resistance in the electrodes, current collectors and interconnects, and contact resistances. Mass transport losses – Limit of getting the reactants to the active catalyst surface At low current densities (jo < 1 mA cm-2), electrodes gives a larger Rtr and therefore overpotential, η should be greater than 400 mV (at RT). An extremely active electrocatalyst is needed to overcome this initial voltage drop in the E – I curve. Best electrocatalysts – Pt based materials 85 86 87 88 89 The higher ORR activity in the case of as-synthesized catalyst (4 nm) compared to the commercial catalyst (2.8 nm) is due to, As the particle size increases, there should be an increase in the number of Pt atoms on various crystal facets (order of ORR activity in aq. H2SO4 is, Pt(111) < Pt(100) < Pt(110)) increases with respect to those at edges and corners. Under the operating conditions of fuel cell, especially in the presence of electric potential there should be a drastic change in the geometries, charges and adsorption energies of the species on a catalyst surface and preferential exposure of Pt in particular orientation. As a result, population of the antibonding 2π* orbitals in oxygen molecule increases and facilitates the reduction of oxygen to water. Hammer and Norskov concept: Metal reactivity changes through the changes in adsorbate– surface interaction energy due to the attraction of the local d-band position relative to the Fermi level. Since the Pt particles are anchored on the surface of carbon in the case of as-synthesized catalyst (evident from TEM images), restructuring of particles which can induce steric and electronic differences among the catalytic sites was more favorable and facilitates the oxygen reduction. The anion (sulfate) effect on the specific activity at a given potential is comparatively stronger for the smaller (d<3 nm) Pt nanoparticles. This effect is generally ascribed to the impeding effect of specific anion adsorption on different crystal faces, the distribution of which changes with Pt particle size. As a result, there should be a less availability of oxygen at the surface Pt atoms (mass transfer limitations) and consequently lower oxygen reduction activity on small size Pt particles present in the commercial Pt/C (2.8 nm) catalyst compared to that of the as-synthesized catalyst (4 nm). 90 Inhibiting or shifting the onset potential (approximately 800 mV vs RHE for Pt) of Pt-OH formation, providing free sites for molecular oxygen adsorption, is generally expected to lower the overpotential losses. A number of prior reports have provided indirect evidence to the possibility of inhibiting the formation of anodic activation of water for Pt-OH formation. Shifting the onset potential of OH formation on Pt is dependent on (a) the ability of the alloying elements to modify the Pt electronic and short-range atomic order for inhibiting activation of H2O and (b) the ability of the alloying element to attract and hold H2Oads more strongly than the surrounding surface Pt atoms. 91 The Pt d-band vacancies were derived from analysis of the Pt L3 and L2 white lines of XANES. The L2 and L3 excitations are due to the transition of 2p1/2 and 2p3/2 electrons to the empty Fermi level. Dipole selection rules restrict the orbital angular quantum number transitions to (1. Hence a transition of 2p3/2 to a 5dorbital is favored. An increase in the L3 and L2 white line peak is related to changes in d-band vacancy and reflects the extent of d-band occupancy. A detailed description of this methodology is provided in ref 2 and references therein. The Pt d-band occupancies evaluated from the Pt L3 and L2 edge curves are given in Table 2 along with the Pt-M atomic ratio. Comparison at 0.54 V vs RHE shows an increase in d-band vacancies per atom on alloying, this follows the trend Pt/C < PtFe/C < PtCo/C. This increase in d-band character of Pt follows closely with the electron affinity of the alloying metal. XANES also offers the ability to monitor the extent of alloying and the nature of the active surface. (J. Phys. Chem. B 2004, 108, 11011-11023). 92 d-band vacancies • The XANES region of the Pt LIII and LII absorption edges can be used to determine the fractional d-electron occupancy of the Pt atoms in the catalyst sample by a so-called white line analysis. • comparison of the white line intensities of a sample with those of a reference metal foil provides a measure of the fractional d-electron vacancy, fd, of the absorber atoms in the sample. fd is defined as follows: where A3,r represents the area under the white line at the LIII edge and A2,r represents the area at the LII edge of the reference foil spectrum • fd can then be used to calculate the total number of unoccupied d-states per Pt atom in the samples as follows: 93 Since the intensity of the L3 and to a lesser extent the L2 peaks increase with Pt d-band vacancy, they can been used to make quantitative determination of Pt d-band occupancy. On the basis of this premise, it has been shown3' that the difference in areas under the Pt L3 and L2 absorption edges between the test sample (WC and Pt alloy electrocatalyst) and a pure Pt reference foil provides the fractional change in the number of d-band vacancies relative to the reference material (fd) using the relation where AA3 and AA2 can be expressed as Here A2 and A3 refer to the area under the L3 and L2 absorption edges of the sample (s) and reference (r) material. The total number of unoccupied d-states, characterized by the total angular moment J ((hJ)total = h3/2 + hy2) for pure Pt, has been evaluated from band structure calculations to be 0.3.29330 Therefore the d-band vacancies of Pt in the sample can evaluated using the expression: 94 Why carbon materials are used as an electrocatalyst support ? Electrochemical properties - Wide electrochemical potential window Chemical properties - Good corrosion resistance Electrical properties - Good conductivity Mechanical properties - Dimensional & mechanical stability - Light weight & adequate strength 95 Oleic acid Pale yellow or brownish yellow oily liquid C18H34O2 (or) CH3(CH2)7CH=CH(CH2)7COOH) (9Z)-octadec-9-enoic acid Oleylamine C18H37N 96