A new column-free approach for antibody

advertisement

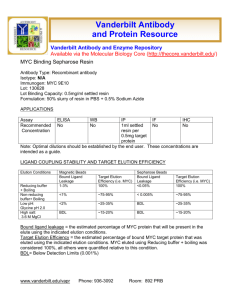

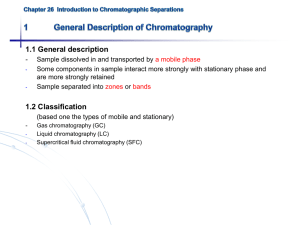

Continuous Antibody Capture with Protein A Countercurrent Tangential Chromatography: A New Column-Free Approach for Antibody Purification Andrew L. Zydney Department Head and Walter L. Robb Family Chair Department of Chemical Engineering The Pennsylvania State University Presented at the ECI Conference on Integrated Continuous Biomanufacturing Castelldefels, Spain, October 21, 2013 Continuous Bioprocessing • Significant potential opportunities – Reduced capital costs / facility requirements – Higher productivity – Easier scale-up • Major technology developments in place – Perfusion bioreactors – In-line filters • Critical challenge is chromatography Chromatography Options • Multi-column periodic counter-current chromatography (PCC) – GE Healthcare • Simulated moving bed chromatography (SMB) – Semba, Tarpon, Contichrom • Sequential multi-column chromatography (SMCC) – Novasep • These approaches typically do not provide truly steady-state operation, potentially leading to variability in product quality Example: SMB New Developments in Simulated Moving Bed Chromatography Seidel-Morgenstern, Kessler, and Kaspereit Chemical Engineering Technology, 31: 826 (2008) Objectives • Develop and demonstrate a new technology that can provide truly continuous protein purification using available chromatography resins, e.g., Protein A • Design criteria: – Comparable yield and purity to columns – High productivity (10x packed columns) – Single use capability (no stainless steel) Countercurrent Tangential Chromatography - CTC Chromatographic resin (beads) flows as a slurry through a series of static mixers and hollow fiber membrane modules All operations (binding, washing, elution, stripping, equilibration) performed directly on the slurry Countercurrent staging used to reduce buffer and resin requirements, increase product yield and purity Continuous CTC System Slurry Tank Binding Washing Elution Stripping Regnera -tion Waste Waste Waste Feed Tank Waste Product Tank True moving bed Conveyor like process Resin slurry moves counter-currently to buffer in each step Chromatographic “Stage” Koflo static mixer Provides residence time needed for equilibration in binding and elution steps Excellent radial mixing with + Spectrum hollow fiber module minimal pressure drop Provides complete separation between resin particles and fluid phase High single pass conversion with low pressure losses Continuous CTC System Centrate Feed Equilibra -tion Permeate UF Step Stripping Permeate Equilibra -tion Buffer Equilibration Wash 2 Permeate Stripping Buffer Stripping Elution Wash 1 Permeate Elution Buffer Wash 2 Buffer Wash 2 Binding Permeate Wash 1 Binding Resin Tank Wash 1 Buffer Product Tank UF Permeate Countercurrent Staging - Elution Stage 1 Resin Slurry from Wash Stage 2 Resin Slurry to Strip Washing 2nd stage 1st stage pH 3 Elution Buffer Purified mAb Countercurrent Staging - Elution Stage 1 Resin Slurry from Wash Stage 2 Resin Slurry to Strip Washing 2nd stage 1st stage pH 3 Elution Buffer Purified mAb Countercurrent Staging - Elution Stage 1 Resin Slurry from Wash Stage 2 Resin Slurry to Strip Washing 2nd stage 1st stage pH 3 Elution Buffer Purified mAb Countercurrent Staging - Elution Stage 1 Resin Slurry from Wash Stage 2 Resin Slurry to Strip Washing 2nd stage 1st stage pH 3 Elution Buffer Purified mAb Countercurrent Staging - Elution Stage 1 Resin Slurry from Wash Stage 2 Resin Slurry to Strip Washing 2nd stage 1st stage pH 3 Elution Buffer Purified mAb Example: 3-Stage Elution Step Concentrated slurry with bound product Elution Buffer Static mixer Tangential flow filter P Product P R Tangential flow filter Static mixer R P Static mixer Tangential flow filter R Concentrated resin slurry Effect of Staging – Elution Step Number of stages Experimental yield Theoretical yield 1 78 ± 2% 77% 2 94 ± 2% 94% 3 98 ± 1% 98% qp = permeate flow rate qr = retentate flow rate n = number of stages Results for qp / qr = 0.75 From Shinkazh et al., Biotech. Bioeng, 108: 582 (2011) Experimental System • Clarified cell culture fluid (Fujifilm Diosynth) – Monoclonal antibody product • POROS® MabCapture A resin – Life Technologies – 45 µm diameter particles, Protein A ligand • MidiCros® hollow fiber modules - Spectrum Lab – 0.5 µm PES membranes, 1 mm ID, 200 cm2 area • Static mixers – Koflo Corportation – 29 cm length, 1 cm ID Feed: 10% slurry, 100 mL/min 1.4 290 TMP Flux 1.2 260 1.0 230 0.8 200 0.6 170 0 500 1000 Time, t (s) 1500 2000 Filtrate Flux, Jv (L m-2 hr-1) Transmembrane Pressure, TMP (psi) Critical Filtrate Flux Feed: 10% slurry, 100 mL/min 1.4 290 TMP Flux 1.2 260 Critical Flux 1.0 230 0.8 200 0.6 170 0 500 1000 Time, t (s) 1500 2000 Filtrate Flux, Jv (L m-2 hr-1) Transmembrane Pressure, TMP (psi) Critical Filtrate Flux • Critical flux corresponds to 80% conversion using 10% slurry Feed: 10% slurry, 100 mL/min 1.4 290 TMP Flux 1.2 260 Critical Flux 1.0 230 Operating Flux 0.8 200 0.6 170 0 500 1000 Time, t (s) 1500 2000 Filtrate Flux, Jv (L m-2 hr-1) Transmembrane Pressure, TMP (psi) Critical Filtrate Flux • Critical flux corresponds to 80% conversion using 10% slurry • System design: – 7.5% slurry – 75% conversion • Extra safety limit enables stable operation for long times CTC Process using Protein A Operation Numbe r of stages Buffer pH Mixed pH Binding 2 -- 7.4 7.6 Wash 1 3 20 mM Na2HPO4 + 0.5 M NaCl 7.1 7.5 Wash 2 3 20 mM Na2HPO4 7.2 7.0 Elution 3 40 mM Citrate 3.2 3.3 Strip 2 10 mM HCl + 0.1 M NaCl 2.0 2.5 Equilibration 2 20 mM Na2HPO4 8.1 7.0 Multiple Runs Feed Flow mAb Rate Load per (L/hr) Resin Run mAb (g/L) mAb Load Run Time 1 – feasibility 1.2 16 g 3 hr 4.5 190 g/L 2 – long time 0.72 8g 24 hr 0.45 470 g/L 3 – high titer 4.5 8g 4 hr 0.45 230 g/L Pressure, P (psig) Run 1 - Pressure Profiles 12 • Stable operation 10 • Pressure <10 psi • Laminar flow 8 • All plastic tubing and connectors 6 4 2 0 0 0.5 1.0 1.5 2.0 Elapsed Time, t (hr) 2.5 Run 1- mAb Purification Absorbance SEC Profiles Elution Pure mAb CCCF • >95% yield • >98% purity • Productivity of 63 g mAb/L resin/hr (10x packed column) • No detectable protein aggregates • No detectable changes in resin Elution Time, t (min) Run 1 - mAb Purification Sample Clarified Harvest • • • • Host Cell Protein (ppm) 675,000 CCTC System 1,200 Packed Column 2,800 Host cell protein measured relative to mAb via ELISA HCP level in CCTC system 2x lower than packed column Yield >95%, purity >98% Similar levels of high MW to purified (reference) mAb Run 2 – Product Profile 1 • Steady-state with respect to product concentration and impurity profile UV - Elution 0.8 0.6 • Long time operation possible 0.4 • For t > 12 hr hollow fiber modules had to be replaced due to bacterial growth 0.2 0 0 2 4 6 8 Time (hours) 10 12 Run 2 – HCP levels HCP Concentration (ppm) 10000 • HCP level remains constant throughout 24 hr run 8000 • >95% purity 6000 • Productivity of 19 g mAb/L resin/hr (reduced due to low titer feed) 4000 2000 0 0 4 8 12 16 Time, t (hr) 20 24 Run 3 - mAb Purification • Very low HCP level due to use of high titer feed (4.5 g/L) spiked with purified mAb Sample Host Cell Protein (ppm) 2 hr 310 3 hr 345 • >99% purity 382 • Productivity of 52 g mAb/ L resin / hr 4 hr • HCP measured via ELISA relative to mAb • 2.6 cycles / hr for resin Advantages of CCTC System • Continuous operation with high productivity – All resin used at all times – Steady-state operation with respect to product concentration and impurity profiles • No columns / packing – Reduced labor costs and validation – Greater flexibility in multi-product facilities • Disposable flow path if desired – Potential for single-use systems – Ideal for production of clinical batches Future Opportunities • Use of smaller resin particles – Much better mass transfer less residence time needed in binding and elution steps – Lower hold-up volume greater productivity – No issues with pressure drop for slurry flow • Direct integration with perfusion bioreactor – Opportunity for continuous steady-state processing – Dramatic improvements in overall productivity Summary • Countercurrent tangential chromatography (CCTC) for mAb purification – Continuous and steady-state operation demonstrated for 24 hr – Purity and yield comparable to packed column – Countercurrent staging reduces resin requirements while increasing product yield and purity – Low pressure operation opportunities for disposable single-use flow path – Modular design for enhanced flexibility Acknowledgements • Oleg Shinkazh – Founder and President, Chromatan • Boris Napadensky – VP of Engineering, Chromatan • Achyuta Teella – Senior Scientist at Chromatan, Post-doc at Penn State • Travis Tran – Associate Scientist, Chromatan • Gary Brookhart – Senior Research Scientist, Fujifilm Diosynth Funding / Support