Barrier Layers for Copper ULSI metallization

advertisement

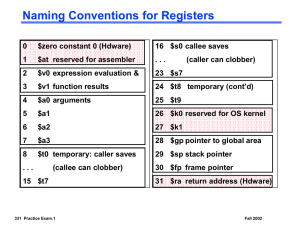

AMC2000 Barrier Layers Technology Prof. Yosi Shacham-Diamand Department of Physical Electronics Tel-Aviv University, Tel-Aviv 69978 ISRAEL AMC2000 1 Jump to first page AMC2000 - tutorial Outline Introduction Copper Interconnect technology Barrier layers - overview Process development and integration Barrier layers modeling Barrier analysis, testing & monitoring Summary AMC2000 2 Jump to first page AMC2000 - tutorial Introduction Structure of Microchips ULSI metallization technology Metallization roadmap Downscaling issues Performance issues Manufacturing issues Where is the bottom ? AMC2000 3 Jump to first page AMC2000 - tutorial Copper multi-level metallization AMC2000 4 Jump to first page AMC2000 - tutorial IBM CMOS 7S process AMC2000 5 Jump to first page AMC2000 - tutorial Copper chips... IBM power PC 750 Mitsubishi Electric eRAMTM family AMD K7(Athalon) UMC 0.18 mm process Motorola 333MHz SRAM Lucent & Chartered 0.16 mm process AMC2000 6 Jump to first page AMC2000 - tutorial IBM PowerPC 750 AMC2000 7 Jump to first page AMC2000 - tutorial Structure of microchips Interconnect network - 6-7 layers of metallization Active devices layer ( 1-2 mm) Silicon substrate (600-800 mm) AMC2000 8 Jump to first page AMC2000 - tutorial ULSI metallization technology אינטל 20009 AMC2000 Jump to first page AMC2000 - tutorial Gate and Interconnect delays AMC2000 10 Jump to first page AMC2000 - tutorial Delay modeling - the barrier effect The specific resistance (rb ) of the barrier layers is higher than that of the Cu, (rCu) W H Without barrier: L: line length R w/o ρCu L WH With barrier (tb: barrier thickness) AMC2000 1 RW (W 2t b )(H 2t b ) 1 2t b (H W2t b ) L ρB L Cu ρ1 Assumption: complete barrier coating 11 Jump to first page AMC2000 - tutorial Cu Damascene interconnect resistivity AMC2000 12 Jump to first page AMC2000 - tutorial Effect of the barrier layer on the interconnect delay Interconnect delay Tint ~ Rint*Cint - including the barrier. In the case of a Damascene technology: Tint Tint, w/o barrier rb rCu 1 ( H tb )(W 2 tb ) rb 1 WH rCu For rb >> rCu we get the the interconnect delay increases as the ratio between the actual copper line cross section and the total cross section. AMC2000 13 Jump to first page AMC2000 - tutorial Barrier layers - overview Why do we need barriers ? Requirements from barriers AMC2000 14 Jump to first page AMC2000 - tutorial Barrier layers for Cu metallization Why do we need barrier layers? Copper affects Si properties Cu affects SiO2 properties Cu affect most insulators properties Cu adheres poorly to bottom and side ILD Why do we need a top barrier (capping layer) Cu corrodes Cu adheres poorly to top ILD AMC2000 15 Jump to first page AMC2000 - tutorial Requirements from barrier layers • Step coverage on high aspect ratio holes and trenches •Low thin film resistivity •Adhesion to the ILD •Adhesion to Cu •Stable at all process temperatures •Process compatible to the ILD •Process compatible to CMP •Act as a good barrier AMC2000 16 Jump to first page AMC2000 - tutorial Barrier layers - types Sacrificial Stuffed - impurities in the grain boundaries Amorphous - no grain boundaries AMC2000 17 Jump to first page AMC2000 - tutorial Diffusion barrier - classification of the candidates for barriers that has been investigated in the last 15 years transition metals transition metal alloys transition metal - silicon transition metal nitrides, oxides, or borides Miscellaneous: ternary alloys, a-carbon, etc. AMC2000 18 Jump to first page AMC2000 - tutorial Summary of barrier layer classification Transition metals fail as barrier at lower temperatures than their nitrides transition metal silicides fail due to the reaction of the Si with the Cu. The reaction is most likely to happen at the grain boundaries Amorphous barriers offer very high reaction temperatures, however, they have very high specific resistivity The barrier properties depend also on the deposition method. AMC2000 19 Jump to first page AMC2000 - tutorial Process development and manufacturing considerations AMC2000 20 Jump to first page AMC2000 - tutorial Step coverage issues Barrier layer too thick Barrier layer too thin AMC2000 21 Jump to first page AMC2000 - tutorial Coverage issues Nonuniform sidewall deposition: • agglomeration • Bad coverage at the bottom corner - can be amplified if the bottom corner has some overetch of the layer below AMC2000 22 Jump to first page AMC2000 - tutorial The effect of pre-deposition clean on the barrier integrity Physical process in Ar+ ions Reactive clean Problems • Damage to the barrier • Damage to the dielectric • Barrier metal and Cu AMC2000 • Sputtering and re-deposition on the sidewalls 23 Jump to first page AMC2000 - tutorial Copper patterning Dry etch Difficult, expensive Conventional equipment Dual Damascene Fully planar, lower cost, New technology AMC2000 24 Jump to first page AMC2000 - tutorial Cu process options AMC2000 25 Jump to first page AMC2000 - tutorial AMC2000 26 Jump to first page AMC2000 - tutorial AMC2000 27 Jump to first page AMC2000 - tutorial Electroplating solutions • Cu ions - Cu sulfate • Acid - H2 SO4 for pH adjustment • HCl - Affects Cu surface adsorption; Halide ad-layer drives Cu growth. It also acts as a surfactant and stabilizes grain growth. Cu deposition is driven by the desorption of the halides. AMC2000 28 Jump to first page AMC2000 - tutorial Electroplating Based Process Sequence Pre-clean IMP barrier + Copper 25 nm 10-20 nm Electroplating CMP + 100-200 nm AMC2000 Low-cost, Hybrid, Robust Fill Solution Simple, 29 Jump to first page AMC2000 - tutorial AMC2000 30 Jump to first page AMC2000 - tutorial AMC2000 31 Jump to first page AMC2000 - tutorial Diffusion barrier for Copper (I) • PVD Ta,TiN, and TaN Neutrals sputtering Collimated & Non collimated Ions sputtering RF ionized HCM- Hollow Cathode Magnetron • CVD of TiN Iodine or Chlorine based chemistry • CVD of Ta and TaN (or both) Bromide based chemistry • MOCVD of TiN TDMAT & TDEAT AMC2000 32 Jump to first page AMC2000 - tutorial PVD barrier technologies Target Target Target RF Substrate Substrate Substrate Bias DC magnetron sputtering AMC2000 Collimated sputtering IMP - Ionized Metal Plasma 33 Jump to first page AMC2000 - tutorial AMC2000 34 Jump to first page AMC2000 - tutorial Diffusion barrier comparison, (M. Mossavi et al., IITC 98) Properties Ta - IMP TaN - IMP TiN - CVD Resistivity 170 m.cm 250 m.cm 130 m.cm Stress +350 MPa +1500 MPa -750 MPa Barrier performance 6x1016 at/cm3 6x1017 at/cm3 1017 at/cm3 40%/40% 100%/100% 20 1 Sidewall/bottom 20%/40% coverage (0.3mm) CMP selectivity 23 vs. Cu AMC2000 35 Jump to first page AMC2000 - tutorial Vias with IMP TaN AMC2000 36 Jump to first page AMC2000 - tutorial Sputtered WxN barrier AMC2000 37 Jump to first page AMC2000 - tutorial MOCVD TiN Precursors: Tetrakis-dimethylamino Titanium AMC2000 38 Jump to first page AMC2000 - tutorial Other Novel barriers RuO2 r=40-250 m cm TaSiN,TiSiN r=200-600 m cm WBN r=300-10000 m cm CoWP r=20-120 m cm AMC2000 39 Jump to first page AMC2000 - tutorial Electroless barriers Surface activation methods Wet activation (Pd activation) Dry (Ion beam sputtered on Si seed) on SiO2/Si 1. PdCl2 activation 2. Copper on titanium 3. Cobalt on titanium AMC2000 40 Jump to first page AMC2000 - tutorial Advantage of Electroless barriers Conformal Low cost Good quality - low r, low stress can be integrated with electroless copper Barrier Cu AMC2000 ILD 41 Jump to first page AMC2000 - tutorial Co(W,P) barrier layer AMC2000 42 Jump to first page AMC2000 - tutorial Specific resistivity vs. solution composition 1 e 4 9 e 5 log( r) 8 e 5 7 e 5 6 e 5 1 a s d e p o s i t e d f i l m o 2 1 0 0 C a n n e a l i n g 5 e 5 o 3 2 0 0 C a n n e a l i n g 4 e 5 AMC2000 0 . 0 00 . 0 50 . 1 00 . 1 50 . 2 00 . 2 50 . 3 00 . 3 5 + + [ W i o n ] / [ C o] 43 Jump to first page AMC2000 - tutorial Barrier layers modeling •Diffusion models - kinetics •Reaction models - thermodynamics AMC2000 44 Jump to first page AMC2000 - tutorial AMC2000 45 Jump to first page AMC2000 - tutorial Equilibrium thermodynamics of diffusion barriers (C.E. Ramberg et al., Microelectronics Microengineering, 50 (2000) 357-368) Cu makes silicides with silicon Barriers include transition metal+metaloid (Si,B,or N) Binary Solid system solution TM-N Broad Crystal Tendency structure to aphase Simple Poor Conductivity TM-Si TM-B Narrow Narrow Moderate Fair Complex Good Variable Good Narrow Complex Poor Si-N, AMC2000 BN Very good Good 46 Jump to first page AMC2000 - tutorial Ternary phase diagrams •The lack of Ta-Cu compounds yield a broad range of compositions in equilibrium with Cu. •Ti-rich compositions are expected to react with Cu N N TiN TaN Ti2N Ta2N Cu Ta Cu Cu Ti Cu Ti 4 4 3 CuTi CuTi2 Ti AMC2000 47 Jump to first page AMC2000 - tutorial Barrier Analysis & monitoring Materials science techniques: AES, SIMS, RBS, SEM Electrical characterization: I-V C-V & C-t AMC2000 48 Jump to first page AMC2000 - tutorial Electrical characterization: MOS capacitors ID: Sample Final Structure: MOS1 Reference capacitors Al/SiO2/Si MOS2 Reference capacitor Barrier/SiO2/Si Just the barrier Barrier/Cu/Barrier/SiO2/Si Copper between top and bottom barrier layers MOS3 Test device No barrier at all, Al metallization Capacitance measurements: CV: Flat band voltage, interface states Ct : minority carrier lifetime, surface recombination velocity AMC2000 IV &It: metal/insulator integrity. 49 Jump to first page AMC2000 - tutorial Ideal MOS capacitance-voltage curve. Solid curve - High f , Dotted curve Low frequencies. Oxide thickness is 140. NA = 1·1015 cm-3. 1.0 Low frequency 0.8 C/COX 0.6 0.4 High Frequency capacitance Low Frequency capacitance High frequency 0.2 Relaxation 0.0 High frequency - fast sweep AMC2000 50 -4 -3 -2 -1 0 1 2 3 4 5 Voltage (Volt) Jump to first page AMC2000 - tutorial Example: test of CoWP barrier layers AMC2000 51 Jump to first page AMC2000 - tutorial CV characteristics of MOS capacitor with a. Co(W,P)/Co and b. Co(W,P)/Cu/Co(W,P)/Co metallization after 300ºC 30 min. and 520ºC for 2 hours anneal. (A= 3.57·10-4 cm2). (a) 1.0 1.0 After 300C, 30’ After 520C, 30’ 0.6 0.6 0.4 0.4 0.2 0.2 0.0 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 Voltage (Volts) After 300C, 30’ After 520C, 30’ 0.8 C/Cox 0.8 C/Cox (b) 0.0 -6 -5 -4 -3 -2 -1 0 1 Voltage (Volts) 2 3 4 AMC2000 52 Jump to first page 5 6 AMC2000 - tutorial C-t curves of Co(W,P)/Cu/Co(W,P)/Co/SiO2 capacitors annealed at 400C, 500C and 520C. Device area is 3.57·10-4 cm2. 6.0E-12 520C, 2 hours hours 500C, 30 min 400C, 30 min. 5.8E-12 Capacitance [F] 5.6E-12 5.4E-12 5.2E-12 5.0E-12 4.8E-12 4.6E-12 4.4E-12 AMC2000 0 53 50 100 150 200 250 300 350 400 450 500 550 600 Ti me (sec) Jump to first page AMC2000 - tutorial Generation lifetime, tg (sec), and Surface Recombination velocity, So, (cm/sec) Al/Co Anneal tg conditions (ms) As-deposited 65 55 300C, 30’ 400C, 30’ 500C, 30’ 520C, 2 hr 600C, 4 hr CoWP/Co So So tg (ms) 3.2 74 2.1 1.6 63 0.9 46 1.3 - CoWP/Cu/CoWP/Co So tg (ms) 58 1.2 62 1.3 52 2 17 0.9 8 1.3 1-2 0.8 AMC2000 54 Jump to first page AMC2000 - tutorial Copper profiles as measured by AES. The sputtering rate was: 12A/min for Co(W,P) on Cu, 25 A/min for Cu, 10A/min for Co(W,P) on Co, 8A/min for the sputtered Co. Co(W,P) Cu Co(W,P) Co SiO2 Si 40 As deposited Concentration (Arb.) 35 30 520C, 2hr 25 600C, 4hr. 20 15 10 5 0 AMC2000 0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 Sputtering Time (min) 55 Jump to first page AMC2000 - tutorial Barrier monitoring techniques X-Ray fluorescence (XRF) thickness and composition (accurate, 5-10 points / min) X-Ray reflection: Thickness (Most accurate, 2-5 points / min)) Ellipsometry: Thickness (low accuracy, fast) Resistivity Others…….?..? AMC2000 56 Jump to first page AMC2000 - tutorial X-Ray reflectivity - Sputtered TiN dBarrier=30.5 nm, r=5.2 gr./cm3 AMC2000 57 Jump to first page AMC2000 - tutorial References Shi-Qing Wang, “Diffusion barriers for Cu metallization on Silicon”, Proceedings of the advanced metallization conference, MRS publications, San-Diego, 1993. The proceedings of the Advanced metallization conferences from 1993 to 1999 The proceedings of the Workshop for Advanced Metallization (MAM) from 1997 and 1999 Papers in various journals such as the Journal of electrochemical society, Journal Vac. Sci.Tech., J. of Appl. Phys., J. Material research and more. AMC2000 58 Jump to first page AMC2000 - tutorial Conclusions Dominant barriers for Cu technology are Ta (IMP), TaN (IMP) & TiN (CVD) There are still problems, especially in high aspect ratio features Other barriers are under study (amorphous, electroless, etc.) Barrier technology is an enabling technology for ULSI metallization AMC2000 59 Jump to first page