Bromobutane Slides ()

advertisement

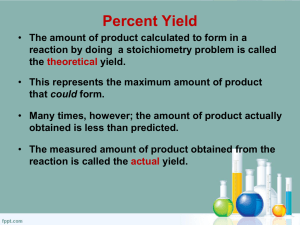

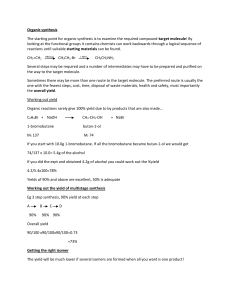

Bromobutane Halogenoalkanes Halogenoalkanes are hydrocarbon chains that have one or more hydrogen atom(s) exchanged for halogen atom(s). Module 2 Describe the laboratory preparation of a halogenoalkane from the corresponding alcohol, with specific reference to refluxing, using a separating funnel, removal of acidic impurities, drying, simple distillation. Preparation of 1-Bromobutane from the corresponding alcohol Bromobutane is prepared by reacting butan-1-ol with hydrogen bromide. C4H9OH + HBr C4H9Br + H2O Preparation of Reaction Mixture Butan-1- ol, solid sodium bromide and water are put into a pear shaped flask. Concentrated sulphuric acid is added from a tap funnel, slowly, in order to dissipate heat as this is a very exothermic reaction. Preparation of Reaction Mixture Hydrogen bromide is made in situ (this means in the reaction mixture) by the reaction between concentrated sulphuric acid and sodium bromide. H2SO4 + NaBr NaHSO4 + HBr The HBr then reacts with butan-1-ol. C4H9OH + HBr C4H9Br + H2O During the preparation brown fumes are observed. The concentrated H2SO4 oxidises HBr producing bromine. This is a side reaction. 2HBr + H2SO4 Br2 + SO2 +2H2O So excess NaBr and concentrated sulphuric acid must be used. Reflux The reaction mixture is then refluxed for 30 – 45 mins. Reflux Continuous evaporation and condensation used to prevent loss of a volatile liquid. This allows an organic reaction mixture to be heated without losing any reactants or products. Condenser in a vertical position. First Distillation The mixture is allowed to cool and is then distilled until no more oily drops of 1-bromobutane carry over. This separates the 1-bromobutane from the reaction mixture. Water Out Water In Use of A Separating Funnel Separating funnels are used to remove impurities from crude organic liquids. The organic liquids are shaken with an aqueous solution and then the organic layer is separated from the aqueous layer. Use of A Separating Funnel Washing with water removes water soluble impurities. Washing with sodium carbonate or sodium hydrogencarbonate solution removes acidic impurities. Separating Funnel Removal of Acidic Impurities A separating funnel is used to shake the crude bromobutane with sodium hydrogencarbonate solution to remove the acidic impurities. 2NaHCO3 + H2SO4 Na2SO4 + 2H2O + 2CO2 NaHCO3 + HBr NaBr + H2O + CO2 Because carbon dioxide is produced pressure builds up inside the funnel and it is necessary to release the pressure periodically by inverting the funnel and carefully opening the tap. Aqueous or Organic Layer? The separating funnel is left to settle. Two layers are formed – an aqueous layer and an organic layer. To find out which is the aqueous layer add a few drops of water – the layer that increases in size is the aqueous layer, the other the organic layer. Drying the Product – Removal of Water In this preparation the organic layer is the bottom layer. 1-bromobutane in the organic layer is run off into a conical flask A drying agent such as anhydrous sodium sulphate is added and the conical flask is swirled. Other Drying Agents Anhydrous Magnesium Sulphate Anhydrous Calcium Chloride The bromobutane is then filtered and redistilled into a pre-weighed clean, dry conical flask. The flask is then weighed and the actual yield is calculated. The percentage yield can be calculated. Percentage Yield % YIELD = Actual Mass x 100 Theoretical Mass Theoretical Yield 8.1g butan-1-ol 0.109 moles C4H9OH + HBr C4H9Br + H2O Therefore 0.109 moles of bromobutane is theoretical yield. 0.109 x 137 =14.93g Percentage Yield Actual Yield = 7.77g % YIELD = Actual Mass x 100 Theoretical Mass % YIELD = 7.77 14.93 = 52.04% Referring to practical and theoretical considerations why is the % yield is not 100%? Practical: Loss during transfer Loss during distillation Theoretical : Side reactions Reaction does not go to completion.

![AL Chem Written Practical (Organic Chemistry) [F.7]](http://s2.studylib.net/store/data/005797652_1-4911d95dd6c8a0840f727bd387aa6027-300x300.png)