Surfactant Adsorption Reduction

advertisement

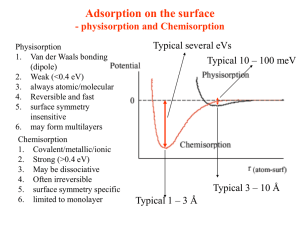

Chemical Engineering Department Towards Reducing the Adsorption of Surfactants on Carbonate Minerals Hadi ShamsiJazeyi, George J. Hirasaki April 2011 2 Agenda • Introduction • Problem Definition • Adsorption • Methods • Results and Discussions • Conclusion 3 Introduction 4 Why is Surfactant Adsorption important in EOR? • Enhanced Oil Recovery (EOR) • Surfactant Adsorption & EOR Economy of Surfactant Injection Chromatographic Separation Wettability Alteration 5 Problem Definition 6 NIB Used in Chemical Flooding • Neodol-67 : • IOS15-18 • Lauryl Betaine NIB-Blend • Previously used for ASF (Alkaline Surfactant Foam) in our group • Mobility Control + Low Interfacial Tension 7 What Caused this Retardation? NIB on Carbonate showed a retardation: CHROMATOGRAPHIC SEPARATION? (ADSORPTION) or DELAY in FOAM FORMATION? 8 Adsorption 9 Adsorption of NIB • To evaluate adsorption of NIB We investigate adsorption of NI and adsorption of Betaine, separately. • Why? Easier to measure the concentration Effect of NI and B can be determined separately on the adsorption 10 Sacrificial Agents 11 Our Tested Choices as Sacrificial Agent • Succinic Acid • Propionic Acid • Sodium Poly acrylate 12 Methods 13 Surfactants Used Trade or descriptive name Chemical Structure Lot # Activity (%) Supplier Neodol-67 bC16-17(CH3-CH-CH2-O)3-SO3 16920-12765-1.00 22.88 STEPAN IOS15-18 R-CH(OH)-CH2-CH(SO3)-R (~75%) R-CH=CH-CH(SO3-)-R (~25%) where R+R’ = C12-15 16920-113005-1.15 21.29 STEPAN Lauryl Betaine (CH3)- (CH2 )11 - (CH3 )2 N+-(CH2 )-COO- 101502 29 RHODIA 14 Procedure for Static Adsorption Experiment • Limestone Sand (Mesh 20-40) • 24 h equilibrium time • Measurement using potentiometric titration For NI-Blend: Hyamine 1622 For Betaine: Sodium tetraphenylborate N:I:B=4:1:10 15 Results & Discussions 16 0.15 wt% initial concentration of NI-Blend Different weights = 2,3,4,4.5,6 (g) Room temperature, Limestone Sand (20-40) 24 (h) shaking 3.5 % NaCl, 10 (cc) solution used Adsorption (mg/g) Adsorption isotherm of NI-Blend on Limestone Sand • Relatively low Adsorption 0.2 0.18 0.16 0.14 0.12 0.1 0.08 0.06 0.04 0.02 0 0 0.025 0.05 0.075 0.1 0.125 Equilibrium Concentration (wt%) 17 Sacrificial Agents and Adsorption of Surfactants on Limestone Sand 1.2 1.2 Betaine NI-Blend 1 Adsorption (mg/g) Adsorption (mg/g) 1 0.8 0.6 0.4 0.2 0.8 0.6 0.4 0.2 0 0 None Succinic Polyacrylate Propionic 0.6 wt% initial concentration of Betaine, Room temperature, Limestone Sand (20-40) 24 (h) shaking, 5(cc) NI-Blend + 5(cc) sacrificial agent Simultaneously added. solution, 3.5 wt% NaCl, solid weights = 4 (g). Concentration of sacrificial agents = 1.2 wt% None Succinic Polyacrylate propionic 0.3 wt% initial concentration of NI-Blend, Room temperature, Limestone Sand (20-40) 24 (h) shaking, 5(cc) NI-Blend + 5(cc) sacrificial agent solution, Simultaneously added, 3.5 wt% NaCl, solid weights = 4 (g). Concentration of sacrificial agents = 0.6 wt% 18 Conclusions 19 Conclusions • On Limestone sand: Adsorption of Lauryl Betaine >> Adsorption of NI-Blend • Polyacrylate had the best results comparing to some other materials in reducing adsorption of NI and Betaine on limestone sand 20 Future Work • Polymeric Sacrificial Agent vs. Same Monomeric ones • Effect of Equilibrating Sacrificial Agent Before Equilibrating Surfactant on Adsorption Reduction • Other Sacrificial Agents • Other Mechanisms of Adsorption • Optimal Concentration of Sacrificial Agents needed • 1D Dynamic Adsorption • How Reducing Adsorption can affect foam mobility in 1D ASF using NIB?