FOOD-CHEMISTRY-IV-Lecture-Unit-2-Carbohydrates-Pectin

advertisement

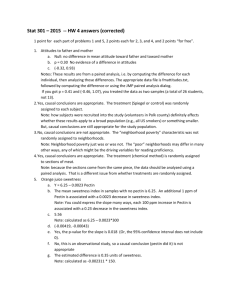

FOOD CHEMISTRY BY DR BOOMINATHAN Ph.D. M.Sc.,(Med. Bio, JIPMER), M.Sc.,(FGSWI, Israel), Ph.D (NUS, SINGAPORE), PDF (USA) PONDICHERRY UNIVERSITY IV lecture 10/August/2012 Goals • • • • • • Pectin structure Pectin ingredients Applications of Pectin in food industry Different Gum structure Physico-chemical properties Applications of Gums in food industry Plant cell wall Pectin Pectin Pectin Monomer: D-galacturonic acid, L-rhamnose Others: D-galactose, D-xylose, D-arabinose short side chain) Bonding: -1,4 -gelling and thickening agents -bound to calcium in the middle lamella -bound to cellulose in the primary cell wall Pectin • Pectic substances – Middle lamellae of plant cell walls – Functions to move H2O and cement materials for the cellulose network • Get PECTIN when you heat pectic substances (citrus peel etc. ) in acid – Not a very well defined material – Pectins from different sources may differ in chemical and functional details Pectin contains: ~85% galacturonic acid Some are esterified with methyl alcohol DE = degree of esterification 10-15% galactopyranose, arabinofuranose & rhamnose 6 Pectin • • • • • • Most pectins have a DE of 50-80% Young unripened plants/fruits have very high degree of esterification hard texture Old ripened plants/fruits have lower degree of esterification softer texture Food use A. Thickener - some use, but less common than gums B. Pectin gels are useful in making jelly and jams 7 Pectin Pectin gels (Jelly) 1. Regular sugar/acid gel • Pectin 0.2 - 1.5% • Low pH from 2.8 - 3.2 (suppresses ionization) - get less repulsion • Sugar (65 -70%) - causes a dehydration of pectin by competing for water through H-bonding • Get gel by charge, & hydration effect Undissociated at low pH No repulsion RAPID SET ESTERIFIED 8 70% SLOW SET – 50 - 70% ESTERIFIED Pectin Pectin gels (Jelly) 2. Low methoxyl pectin gel • < 50% esterified • Get gel due to Ca2+ ion bridging • Avoid need for sucrose (diet foods) • Get gels over wide pH range • Gels tend to be more brittle & less elastic than sugar/acid gels O C O- 9 O C + + Ca -O Low methoxy pectin High methoxy pectin Pectin gel forming mechanism Pectin Pectin Pectin and its characteristics: Example: Citrus juices • Normal juice - colloidal pectin - thickening • Pectin esterase - demethoxylates pectin --loss of thickening-precipitation - due to H-bonding of COOH and Ca2+ bridging • Must heat juice to inactivate enzyme - causes dramatic flavor changes Pectin esterase Loss of precipitation 14 High Methoxy Pectin Partially De-esterified Pectin at low pH Partially De-esterified Pectin Amidated Pectin Pectin Esterase and Lyase Polygalacturonase and Pectin Lyase Pectins • Unbranched polymers of 200 - 1,000 Galactose units, linked b 1-4 Glucosidic bonds • Degree of esterification controls setting rate • >50% High Ester Pectins (HM) • <50% Low Ester Pectins (LM) • 70 - 85% (DE) = Rapid Set • 44 - 65% (DE) = Slow Set • Calcium required to gel LM Pectins • USES: • Amidated LM Pectins used to gel natural fruit preserves • High ester (HM) Pectins stabilize sour milk drinks - react with casein • Low ester (LM) Pectins used for milk gels Gums • Plant polysaccharides (excluding unmodified starch, cellulose and pectin) that posses ability to contribute viscosity and gelling ability to food systems (also film forming) – Obtained from • • • • Seaweeds Seeds Microbes Modified starch and cellulose • All very hydrophilic – Water soluble – Highly hydrated • High hydration leads to viscosity = thickening and stabilizing effect • Also good gel formers – Some form gels on heating/cooling and in the presence of ions 22 Gums Properties depend on: 1) Size and shape 2) Ionization and pH 3) Interactions with other components 23 Gums Properties depend on: 1) Size and shape – Linear structures: • More viscous (occupy more space for same weight as branched) • Lower gel stability get syneresis on storage (i.e. water squeezes out of the gel) – Branched structures • Less viscous • Higher gel stability more interactions 24 Gums Properties depend on: 2) Ionization and pH – Non-ionized gums = little effect of pH and salts – Negatively charged gums • Low pH = deionization = aggregation precipitation – Can modify by placing a strong acidic group on gum so it remains ionized at low pH (important in fruit juices) • High pH = highly ionized = soluble viscous • Ions (e.g. Ca2+) = salt bridges = gels 3) Interactions with other components – Proteins – Sugars 25 Gums Examples of gums and their applications A) Ionic gums • Alginate – – – – From giant kelp Polymer of D-mannuronic acid and L-guluronic acid Properties depend on M/G ratio Highly viscous in absence of divalent cations • – Form gels when: 1. 2. – – pH 5-10 Ca2+ or trivalent ions pH is at 3 or less Used as an ice cream and frozen dessert stabilizer Also used to stabilize salad dressings 26 Alginate Alginate G M G, M Monomer: -mannuronic acid (M) -L-guluronic acid (G) Bonding: -1,4/-1,4 Pectin-Alginate image Algin and Alginate • Polymers of Mannuronic and Galacturonic acids varying widely in ratios of the two acids • Viscosity of 1% solution ranges from 10 to 2,000 CP as a function of molecular weight and calcium ion content • Precipitates below pH 3.0 • Degrades above pH 6.5 • Forms gels with calcium ions - 0.5 to 1.0% calcium • Propylene glycol derivative improves stability to calcium and acid • Food functionality includes: – – – – Water binding Gelling Emulsifying Stabilizing Propylene Glycol Alginate • • • • • Precipitate at low pH Interaction with calcium ions Some interaction with fat "Slimy" mouthfeel can substitute for fat Good foam stabilizer Alginate Gels – Extrude into calcium bath – Use sodium alginate with a sparingly soluble calcium salt – Regulate calcium availability by regulating pH, sequesterant – Too much calcium gives grainy gels – Too slow release gives weak gels Carrageenan Gums A) Ionic gums • Carrageenan – From various seaweeds – Seven different polymers • κ-, ι- and λ-carrageenan most important • Commercial carrageenan is a mixture of these – Polymer is sulfated • Stable above pH 7 (is charged) – Function • Depends on salt bound to the sulfate group – Na+ = cold water soluble and does not gel provides viscosity – K+ = produces firm gel • Improves/modifies function of other gums • Stabilizes proteins – Interacts with milk/cheese proteins 34 Carrageenan: Properties -Most important red seaweed polysaccharides used by food industry. -3 forms differ in sulfate ester -commercial products contain a mixture of 3 fractions -stabilize milk protein -water gel in low-calorie jams and jellies -thickeners/stabilizer (combine with other hydrocolloid) Carrageenan Monomer: D-galactose (anhydro/sulfate) Bonding: -1,4/ -1,3 Kinds of Carrageenan kappa iota Kinds of Carrageenan lambda Carageenan • Source: Seaweed gum • Structure: Linear D-galactopyranosyl chain with alternating 1,3 and 1,4 links. Some residues have one or two sulfate ester residues. Three broad types of repeating structure (i, k, and l carageenan) • Functional Properties: pH independent thickening. Double helix formation in k or i carageenan can lead to gelation. – k-carageenan is used in dairy foods Carrageenans • Mixtures of nonhomogeneous polysaccharides • Galactans having sulfate half-ester groups attached to the sugar units • Extracted from red seaweeds • D-galactopyranosyl units joined with alternating (1 3)-a-D- and (1 4)-b-D-glycosidic linkages, with most sugar • units having one or two sulfate groups esterified to a hydroxyl group at carbon atoms C-2 or C-6 Carrageenans • Sulfate content-15 to 40% • Carrageenan products dissolve in water to form highly viscous solutions. • The viscosity is quite stable over a wide range of pH values because the sulfate half-ester groups are always ionized, even under strongly acidic conditions, giving the molecules a negative charge.