impact of molecular weight on material properties

advertisement

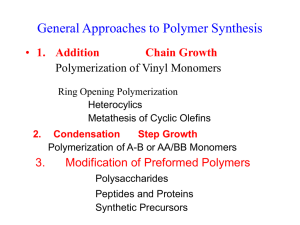

CHEM 7010 Macromolecular Synthesis 2nd Introduction to Polymer Synthesis: General Aspects of Polymer Structures on Polymer Properties 2011 Multidimensional Order of Structure-Property Relationships in Polymers Microscopic Molecular Microscopic *Crystallinity *Phases *Orientation Synthesis and Molecular Processing *Chemical Composition Macroscopic *MW/MWD *Branching and/or Cross-linking *Strength Macroscopic *Modulus *Impact Resistance Permeability Clarity IMPACT OF MOLECULAR WEIGHT ON MATERIAL PROPERTIES Increasing Degree of Polymerization, DP High Density PE Properties Brittle Wax Tough Wax melting point Low Density PE Oligomers density crystallinity Tensile Strength Elongation Molecular Weight Vinyl Monomers, CH2=CH-X • • • • • • • • X H CH3 Cl Phenyl CN COOCH3 O-COCH3 Polymer Abbreviation Polyethylene PE Polypropylene PP Poly(vinyl chloride) PVC Polystyrene PSt Polyacrylonitrile PAN Poly(methyl acrylate) PMA Poly(vinyl acetate) PVAc Vinylidene Monomers, CH2=C(X)Y • X • • • • • Y Polymer Abbreviation CH3 CH3 Polyisobutylene PIB Cl Cl Poly(vinylidene chloride) PVDC F F Poly(vinylidene fluoride) PVDF Phenyl CH3 Poly(-methyl styrene) CH3 COOCH3 Poly(methyl methacrylate) PMMA • CN COOR Poly(alkyl -cyanoacrylate Structural Complexity of Polymers • Homopolymers • Head to Tail vs. Head to Head Adducts e.g. a-olefins • 1,2- vs 1,4 Adducts; e.g. butadiene • Tacticity of Enchainments • Branching Tacticity • • • • • H Isotactic H X H X X X X X All asymmetric carbons have same configuration Methylene hydrogens are meso Polymer forms helix to minimize substituent interaction Syndiotactic H • • • • • X X X X X X Asymmetric carbons have alternate configuration Methylene hydrogens are racemic Polymer stays in planar zig-zag conformation Heterotactic (Atactic) Asymmetric carbons have statistical variation of configuration Structural Complexity of Polymers • Copolymers • Identity and Number of Comonomers • Ratio and Distribution of Comonomers • Statistical Alternating Gradient • Blocks Grafts Structural Complexity of Polymers • Molecular Weight – Molecular Weight Distribution, MWD – Polydispersity Index, PDI – Mn, Mw, Mz, Mv Averages • Crosslinking Density – Length of Crosslinks Structural Complexity of Polymers Time Dependent Changes • Chemical Reactions • Hydrolysis • Dehydrohalogenation • Photodegradation • Oxidation Structural Complexity of Polymers • Thermal Degradation • Processing • Aging • Crystallization • Changes in Polymorphism • Weathering-- Combination of Above • Plasticizer Loss -- Imbrittlement Microscopic Properties (Intermolecular Interactions) • Morphology • Chain entanglement –amorphous • Chain ordering--liquid crystalline • Crystallinity • Phase separations (microdomains) Types of Intermolecular Forces • Type of Force Relative Strength Low Molecular Analog Polymer • Dispersion or • Van der Waals Weak Methane Hexane Polyethylene Polypropylene • Dipole-Dipole Medium CH3Cl CH3CO2CH3 PVC PMMA H 2O Cellulose CH3CONH2 Proteins CH3CO2-Na+ Ionomers Hydrogen bonding Strong Electrostatic Very Strong GLASS TRANSITION, Tg • Definition: The onset of seqmental motion of seqments with 40-50 carbons atoms • Physical Change Expansion of volume • Free volume required to allow segmental motion • Tg is an approximation • Depends upon measurement technique • Depends upon molecular weight • Polystyrene MW = 4000 Tg = 40C • = 300,000 = 100 GLASS TRANSITION, Tg • Properties Affected • Specific Volume / Density • Specific Heat, Cp • Refractive Index • Modulus • Dielectric Constant • Permeability FACTORS INFLUENCING Tg • Tg is proportional to Rotational Freedom • For symmetrical polymers Tg, / Tm in K 1/2 • unsymmetical polymers 2/3 • 1. Chain flexibility • Silicone Ether Hydrocarbon Cyclic HC Aromatics FACTORS INFLUENCING Tg 2. Steric Bulk of Substituents Tg = -120C 5C -24C -50C •Long side chains may act as plasticizers (C 6) O – Tg = • -55C O 88C FACTORS INFLUENCING Tg • • • • • • • 3. Molecular Symmetry Asymmetry increases chain stiffness. 4. Polar Interactions increase Tg Hydrogen bonding 5. Molecular Weight up to Critical Limit 6. Crosslinking Reduces Segment Mobility FACTORS INFLUENCING Tm • 1. Chain flexibility • Silicone Ether Hydrocarbon Cyclic HC Aromatics • 2. Substituents Producing Lateral Dipoles • Hydrogen bonding • 3. Molecular Symmetry • Symmetry allows close packing FACTORS INFLUENCING Tm • 4. No Bulky Substituents to Disrupt Lattice if placement is Random • 5. Structural Regularity • monomer placement • head to tail • 1,2- vs 1,4• 1,2- vs 1,3- vs 1,4- aromatic substitution • geometric isomers of enchainments • cis or trans -C=C-; cyclic ring • tacticity FACTORS REQUIRED TO PROMOTE CRYSTALLIZATION • Thermodynamic • 1. Symmetrical chains which allow regular close packing in crystallite • 2. Functional groups which encourage strong intermolecular attraction to stabilize ordered alignment. FACTORS REQUIRED TO PROMOTE CRYSTALLIZATION • Kinetic • 1. Sufficient mobility to allow chain disentanglement and ultimate alignment • Optimum range for mobility • Tm -10 Tg + 30 • at Tm segmental motion too high • at Tg viscosity too high • 2. Concentration of nuclei • concentration of nucleating agents • thermal history of sample Macroscopic Properties (Physical Behavior) • Tensile and/or Compressive Strength • Elasticity • Toughness • Thermal Stability • Flammability and Flame Resistance • Degradability • Solvent Resistance • Permeability • Ductility (Melt Flow) Step Polymerization (Polycondensation) After many repetitions: Polyethyleneterephthalate (PET) Step Polymerization Two Routes: A-A + B-B; or A-B 1 on 39 1 on 40 2 on 39 2 on 40 Either way, need: • high conversion • stoichiometric amount Step vs. Chain Polymerization Step Polymerization • Any two molecular species can react. • Monomer disappears early. • Polymer MW rises throughout. • Growth of chains is usually slow (minutes to days). • Long reaction times increase MW, but yield hardly changes. • All molecular species are present throughout. •Usually (but not always) polymer repeat unit has fewer atoms than had the monomer. Step vs. Chain, cont. Chain Polymerization • Growth occurs only by addition of monomer to active chain end. • Monomer is present throughout, but its concentration decreases. • High polymer forms immediately. • MW and yield depend on mechanism details. •Chain growth is usually very rapid (seconds to microseconds). • Only monomer and polymer are present during reaction. • Usually (but not always) polymer repeat unit has the same atoms as had the monomer. Step Polymerization Concepts Comparison of Step and Chain Polymerization 1. Step: any 2 molecules in the system can react with each other Chain: chain growth occurs on end of growing polymer 2. Step: loss of monomer at early stage (dimers, tetramers, etc.) Chain: monomer concentration decreases steadily 3. Step: broad molecular weight distribution in late stages Chain: narrower distribution; just polymer and monomer Step Polymerization Basis for Kinetics (2-1a): 3 on 40 4 on 40 5 on 40 6 on 40 Step Polymerization Basis for Kinetics: 1on 41 2 on 41 Step Polymerization Basis for Kinetics (2-1b): NOTE: Assume equal reactivity of functional groups table 2.1on 42 Thus, assumption looks ok Step Polymerization Kinetics (2.2) Example: diacid + diol O HO O O -n H2O OH + HO OH Mechanism (acid catalyzed): 2 on 44 1 on 45 2 on 45 HO O O OH Chain Polymerization Concepts General Mechanism Initiation I Propagation R* * could be radical, cation, or anion Chain Polymerization Concepts: Nature of Chain Polymerization; 3-1 3-1a. Comparison of Chain and Step Polymerizations 12 10 8 chain 6 4 step 2 0 0 2 Chain: a. Rapid high mw b. Snapshot: monomer, high poly, growing chains c. MW does not change with time 4 6 8 10 Step: a. Monomer gone fast, get dimer, trimer, etc. b. MW increases with time c. No high mw until end Chain Polymerization Concepts: Nature of Chain Polymerization; 3-1 3-1b-1. General Considerations of Polymerizability Thermodynamics (Chain t-fer) Chain Polymerization Concepts: Nature of Chain Polymerization; 3-1 3-1b-2. Effects of Substituents on C=C monomers for Ionic Polymerization A. Initiation opportunities: 2 types of bond cleavage/resonance B. Radical, Anionic, Cationic: Depends on: i. Inductance ii. Resonance Chain Polymerization Concepts: Nature of Chain Polymerization; 3-1 3-1b-2. Effects of Substituents on C=C monomers for Ionic Polymerization C. Donating Groups i. Inductance ii. Resonance e.g. Polym of vinyl ether Good for cationic Example of resonance stabilization of cation by Delocalization of of positive charge. If oxygen not there, no stabilization Chain Polymerization Concepts: Nature of Chain Polymerization; 3-1 3-1b-2. Effects of Substituents on C=C monomers for Ionic Polymerization C. Donating Groups ii. Resonance e.g. Polym of Styrene Chain Polymerization Concepts: Nature of Chain Polymerization; 3-1 3-1b-2. Effects of Substituents on C=C monomers for Ionic Polymerization D. Withdrawing Groups i. inductance Good for anionic ii. resonance Chain Polymerization Concepts: Nature of Chain Polymerization; 3-1 3-1b-2. Effects of Substituents on C=C monomers for radical polymerization A. Radicals not affected by charge, but can have resonance stabilization B. Also stabilized by primary<secondary<tertiary Draw your own pic Chain Polymerization Concepts: Structural Arrangement of Monomer Units; 3-2 3-1a. Possible Modes of Propagation A. Two possible points of attachment i. On carbon 1: ii. On carbon 2: Chain Polymerization Concepts: Structural Arrangement of Monomer Units; 3-2 3-1a. Possible Modes of Propagation B. If attachment is regular, get head-to-tail (H-T) C. If attachment is irregular, get head-to-head (H-H) [and T-T] Chain Polymerization Concepts: Structural Arrangement of Monomer Units; 3-2 3-1a. Possible Modes of Propagation Usually only 1-2% H-H. How do we know? A. Chemical Methods B. NMR Methods (we’ll check this out in the Spectroscopy section)