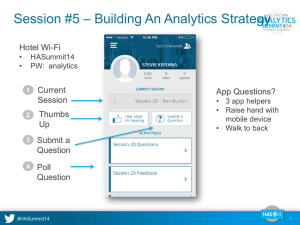

The Development of Metal Catalyzed, One-Step

advertisement

The Development of Metal Catalyzed, OneStep Approaches to α-Amino Acids, Pyrroles and α-Substituted Amides 21/09/2011 Yingdong Lu Who Am I In Canada Ph.D supervisor Dr. B. Arndtsen McGill University PDF supervisor Dr. C. Crudden Queen’s University Direct Synthesis Building Blocks R2 R1 R1 R1 O R1 X R2 R1NH2 R1OH R1-M R2 CO N R3 Metal Catalysis Target Products CO2 Can complex molecules be constructed directly from simple building blocks, via the mechanistic design of new metal catalyzed reactions? Efficient, Green, Diversified A One Pot Synthesis of Münchnones N R1 R2 + H R3 O + CO Cl O 5 mol % Pd cat. NEtiPr2 / Bu4NBr O R1 – N + R2 50-90% 55 oC CH3CN / THF O R2 N H H Pd(0) O O – R1 O C R3 N+ R2 R1 S R3 O Pd O Base.HCl N ClR1 Oxid. add R1 R2 N R3 R2 O + H R3 Cl CO L Sub. R1 R2 N H OCPd R3 O Cl O Cl 3 R1 Pd Cl O N R3 R2 H R1 R2 N Pd cat. = Pd Cl O R R3 R1 H N R2 insertion R3 Dhawan, R., Dghaym, R. and Arndtsen, B. A. JACS 2003,125,1474 2 Münchnone Chemistry O C R1 R1 O N R R2 O R + R A B N N R2 O B 1,3-dipolar R 2 O addition O R1 A R R1 -CO2 N A B Heterocycles ketene reactivity -amino acid derived products Typical Münchnone Synthesis: O available starting materials HO R2 N R1 H R3 O -H2O R2 R1 O Potts, K. In . 1,3-Dipolar Cycloaddition Chemistry, Padwa, A. Ed. ; Wiley: New York, 1984: Vol.2 p.1 O + R2 N R3 Previous Work N R2 H O R2 O R3 R1 Cl R3 N R1 O O MeOH CO Dhawan, R.; Dghaym, R. D.; Arndtsen, B. A. J. Am. Chem. Soc. 2003; 125, 1474. R2 O H R1 N R3 R2 O R3 R4 Cl R3 R1 N N R3 N N Ts R4 H Cl Siamaki, A. R.; Arndtsen, B. A. J. Am. Chem. Soc 2006; 128, 6050. R5 R4 R1 N R2 R2 R4 R5 Dhawan, R.; Arndtsen, B. A. J. Am. Chem. Soc. 2004; 126, 468. R1 H Request from Organic Synthesis R1 N R2 O + H + CO R3 Cl Pd catalyst.= Pd catalyst NEtiPr2/Bu4NBr 55 oC CD3CN O O R1 N+ R2 H R2 R1 N Pd R3 Cl O 2 Scale up failed: no more than 1 mmol of reagents My answer: Need a new catalytic system •How? •Kinetic study to figure out mechanism R3 R1 N + R3 H R2 + CO Cl 55 oC/CD3CN NEtiPr2/Bu4NBr rate α [Pd] rate = 9.67E-05x s -1 R2 = 0.98 rate (s -1) ln([Yield] ∞/([ Yield] ∞ - [Yield])) 2.5 1.5 1 0.5 0 0 5000 10000 15000 0.00016 0.00014 0.00012 0.0001 0.00008 0.00006 0.00004 0.00002 0 20000 R2 = 0.99 0 0.002 tim e (s) 0.004 0.006 0.008 [Pd] (M) rate α CO pressure rate α [base] 0.00012 0.00012 0.00011 0.0001 0.0001 rate (s -1) rate (s -1) R3 N+ R2 R1 rate α [iminium salt] 2 O O Pd cat. O 0.00009 0.00008 0.00008 0.00006 0.00007 0.00004 0.00006 0.00002 0.00005 0 0 0.5 1 1.5 [baae] (M) 2 2.5 0 2 4 6 CO pressure (atm ) 8 10 Mechanism O Rate α [iminium], [Pd], [CO] R3 R2 N R2 Pd(0) O R2 O O C R3 N+ R1 R2 R1 - Cl fast R1 + H R3 H H R2 R1 L N Pd R3 Cl O CO H R2 R1 N OC Pd R3 O Cl O N R3 R1 O Cl R2 H Pd O Base.HCl N O N R3 R1 An e-rich and bulky ligand is need to accelerate Oxidative addition and CO coordination Cl p-tolyl N H O + Ph Bn + Cl Pd cat. (5 mol%) 15% P(o-tolyl)3 CO Ph N+ NEtiPr2 – CH3CN/THF, 55 oC p-tolyl Bn rate α [iminium] rate α CO pressure 3 0.00035 R2 = 0.99 0.0003 -1 2.5 ) rate = 1.5E-04x s -1 R2 = 0.98 reaction rate (s ln([Yield] ∞/([ Yield] ∞ - [Yield])) O O 2 1.5 1 0.5 0 0.00025 0.0002 0.00015 0.0001 0.00005 0 0 2000 4000 6000 8000 10000 time (s) 12000 14000 16000 18000 0 1 2 3 4 5 6 7 CO pressure (atm) Though phosphine ligand accelerate the oxidative addtion, it slow the CO coordination step 8 9 Ligand Effect Ligand Rate Bu4NBr 18h P(oTol)3 6h (tBu)2P(oTol) 4h tBu (tBu)2P(biphenyl) 3h P tBu p-tolyl N H O + Ph Bn + Cl Pd cat. (5 mol%) 15% tBu2P(biphenyl) CO reaction rate (s -1) ln([Yield]∞/([Yield]∞ - [Yield])) 2 1.5 1 0.5 0 0 2000 4000 6000 tiem (s) Ph rate α CO pressure rate = 2.6E-04x s -1 R2 = 0.99 2.5 O N+ NEtiPr2 – CH3CN/THF, 55 oC p-tolyl Bn rate α [iminium] 3 O 8000 10000 12000 0.0005 0.00045 0.0004 0.00035 0.0003 0.00025 0.0002 0.00015 0.0001 0.00005 0 0 2 4 6 8 10 CO pressure (atm) higher reaction rate of both oxidative addition and CO coordination was achieved Large scale Münchnone synthesis (multigram) p-Tol N H O + Bn Ph Cl + O 0.25% [Pd(allyl)Cl]2 CO (20 atm) 0.75% JohnPhos, NEtiPr2, p-Tol CH3CN, 45 oC, 18h O Ph N+ Bn – 89% Pd loading lower to 0.1% Milder reaction condition (room temperature) p-Tol N H O + Bn Ph Cl + CO (4 atm) 5% [Pd(allyl)Cl]2 15% JohnPhos, NEtiPr2, CH3CN, r.t., 48h O O – p-Tol Ph N+ Bn 68% Application: Lipitor Synthesis O O N O O O O H O tBu + Ph tBu O COOMe + Cl O F 5% Pd allylchloride 15% JohnPhos 45 0C 1.5 eq of collidine O N O 48% O O tBu O O N F H N O 95% F NH2 DMF Reflux With Benzyl Protected Product N H + Ph COOMe + Cl F O 5% Pd allylchloride 15% JohnPhos 45 0C 1.5 eq of collidine O N O 65% N F H N O 99% F NH2 DMF Reflux Limitations of N-acyl Iminium Salt Intermediates Limitation of Substituents N R1 O R2 O + H R3 R2 Cl N H R1 and R2 can not be e-withdrawing or bulky R3 can not be enolizable (non-alkyl) Stability of starting materials R3 R1 Cl- Use α-Alkoxy Amides as N-acyl Iminium Precusor? O R1 O R3 N R2 OR R1 R3 N ClR2 Stability Easily synthesized Easily diversified Challenge: activation of the ether C-O bond Oxidative Addition Ethers to Pd ??? O p-Tol + p-Tol N Bn OPh Pd2(dba)3 No reaction CH3CN Oxidative Addition Ethers to Pd ??? O p-Tol + p-Tol N Bn OPh No reaction Pd2(dba)3 CH3CN PdLn O p-Tol p-Tol N Bn OPh L.A C-O bond is too strong to oxidative addition to Pd0 , adding Lewis acid might weak the C-O bond and help the oxidative addition Oxidative Addition to Pd with the Assistance of Lewis Acids O p-Tol p-Tol p-Tol N Bn OPh + 2 BF3 + Pd2(dba)3 RT 15 min MeCN CH3CN -PhOBF2 Pd MeCN O N Bn BF4- p-Tol Pd Catalyzed Amidoester Synthesis O p-Tol p-Tol N Bn OPh + CO 10% Pd catalyst P(o-Tol)3 65 0C CH3CN 10% BF3 O p-Tol p-Tol N Bn 20% O OPh + p-Tol O N H Bn 68% H R2 R1 N MeCN Pd catalyst = Pd R3 MeCN O BF4- Pd Catalyzed Amidoester Synthesis O p-Tol p-Tol OPh + N Bn 0 65 C CH3CN 30% BF3 2h O Bn N p-Tol H quantitative CO 10% Pd catalyst P(o-Tol)3 65 0C CH3CN 10% BF3 O p-Tol p-Tol N Bn 20% O OPh + p-Tol O N H Bn 68% H R2 R1 N MeCN Pd catalyst = Pd R3 MeCN O BF4- BF3 is too strong Lewis acid for this reaction we need something milder Pd Catalyzed Amidoester Synthesis O p-Tol p-Tol N Bn OPh + CO 10% Pd catalyst P(o-tolyl)3 O p-Tol 0.5 Bu4NBr OPh p-Tol N 65 0C CH3CN Lewis Acid Bn O Lewis Acid Yields 0.1eq BF3 20% 1eq Y(OTf)3 0 1eq SnCl4 0 2eq AlF3 72% 0.3 eq AlF3 70% We can carbonylate the C-O bond and generate products that can not be synthesized through imines and acid chlorides Diversity O R1 10% Pd catalyst P(o-tolyl)3 0.5 Bu4NBr 65 0C CH3CN 2 eq AlF3 R3 N R2 + OPh CO O O N O OPh 51% Br OPh N Bn O 55% p-Tol O OPh N O 94% O p-Tol OPh N Bn O OPh O 62% O OPh R3 N R2 O 74% O p-Tol R1 p-Tol N PMB O O O p-Tol N Bn OPh O 74% Lu, Y., Arndtsen, B. A. Org. Lett. 2007, 4395 Directly Activate C-O Bond Without Lewis Acid Problems with the current system: The Lewis acid is expensive Limited functionality Solution: Activate the C-O directly without Lewis Acids. How: Weaken/polarize C-O bond Design better a catalyst O R1 R3 N R2 OR PdLn Carbonylation Without Lewis Acids O P-Tol p-Tol N Bn + OR R CO 10% Pd catalyst P(oTol)3 0.5 Bu4NBr 65 0C CH3CN O p-Tol product N/A N/A O2N N N/A 54% N N/A F3C N/A NO2 p-Tol N Bn OR O Ligand Scanning O p-Tol p-Tol N Bn OPy + CO 10% Pd catalyst/L 0.5 Bu4NBr p-Tol 65 0C CH3CN tBu PPh3 PtBu3 0% 0% 3 P 50% P(o-tolyl)3 54% O p-Tol N Bn OPy O tBu P P tBu tBu 56% 87% Making a more electron rich catalyst allows for efficient C-O activation Direct Lewis Acid-Free Carbonylation O R1 10% Pd catalyst O R3 15%(tBu)2P(biphenyl) OPy 0.5 Bu4NBr R N 1 65 0C CH3CN R2 O R3 N R2 OPy + CO F O O p-Tol OPy N Bn O N Bn O 73% 68% O p-Tol tBu OPy N Bn O 86% O O O OPy p-Tol OPy N Bn O 74% p-Tol OPy N O 85% O p-Tol p-Tol OPy N PMP O 72% Pyrrole Synthesis O R2 N R3 R3 R1 R5 R4 Pyrrole R4 ????? O O R2 – Pd(0) R5 R3 N+ R1 O C R3 H R2 R1 N L Pd R3 Cl O Cl ROH OR CO H R2 R1 N OC Pd R3 O Cl R2 N R3 R1 R1 N R2 O N OR R2 O ROH O R1 O R 2 Pd H O N R1 R3 Pyrrole Synthesis O p-Tol p-Tol N Bn O p-Tol 10% Pd catalyst COOMe 15% P(oTol)3 2 eq AlF3 OPh + CO + Ph p-Tol p-Tol N Bn 65 C, CH3CN 0.5 Bu4NBr OPy + CO + COOPh 50% COOMe 10% Pd catalyst 15% tBu2P(Biphenyl) p-Tol p-Tol N Bn o O Bn N p-Tol 65 0C CH3CN Ph 0.5 Bu4NBr Ph COOMe 67% H R2 R1 N MeCN Pd catalyst = Pd R3 MeCN O BF4- Compared to PhOH, PyOH is a much weaker nucleophile. Diversity O R2 R3 N R1 F3C + OPy CO + R4 Bn N Ph Ph COOMe Bn N Ph 38% Tol Ph Bn N Tol COMe 54% Bn N Ph COOMe R1 N R3 Me Tol Bn N NC R5 Tol Bn N COOMe MeOOC 48% tBu Ph 39% Bn N Tol Tol H R2 R4 62% 69% Tol Tol H R5 Bn N Tol 42% Tol 10% Pd catalyst 15% PtBu2(Ph2) 0.5 Bu4NBr 65 0C CH3CN Tol N H O 58% Tol PMB N Tol Ph COOMe 48% Lu, Y., Arndtsen, B. A. Angew. Chem. Inter. Ed, 2008, 5430 Importance of Asymmetric Synthesis Biological importance DNA, protein, amino acids…. Pharmaceutical importance O Ph N H N F OH HO2C Ph OH Atorvastatin Asymmetric Synthesis Start with chiral starting materials Chiral auxiliaries Chiral resolution Asymmetric catalysis Asymmetric Alkynylation 10% CuCl iPr2NEt O + Ph + N EtO H N -78 oC, 6 h 12% L Cl Ph O OEt CH3 HN N O O N But Ph PPh2 H3CO PPh2 (R)-QUINAP 43% ee 53% ee O PPh2 PPh2 O N N PPh2 81% ee MOP, 0% ee O P NR2 O N Pri (R)-BINAP, 2%ee Ph N N N tBu (R)-tBu-BOX, 1% ee HN N PPh2 N CH3 (R)-iPr-PyBOX, 0% ee iPr MONOPHOS, 0% ee Black, D. A.; Beveridge, R. E.; Arndtsen, B. A. J. Org. Chem. 2008 73, 1906 A Less “Synthetic” Source of Chirality? L L L M L L L Chiral Fragment -Amino Acids Peptides R OH H2N O R1 O H N ... R2 N H OH O Idea: Tunable, Hydrogen Bonding Metal Catalysis O Chiral pool R OH + Substrate NH P LnM R' Tunable catalyst Alkynylation of Imines N R2 R1 O + R3 H O 10% CuI base + Cl R4 H N R3 r.t. 15 min R2 R1 H R4 Black, D.A.; Arndtsen, B.A Org.Lett. 2004, 6, 1107. N R2 R1 R3 + water RT 4d H O L= Ph CuI/L R1 R2 * R3 O N N HN N Ph Li, C.-J. JACS, 2002, 124, 5638. Chiral Bronsted Acids in Asymmetric Catalysis N R 2% catalyst 1.1 equ. acac Boc H R O catalyst HN * R CH2Cl2 r.t, 1h Boc Ac Ac O P O OH R R= 4-(b-Naph)-C6H4 HO OTMS + N R H 10 % catalyst OR2 toluene -78 oC, 17h R1 H Tereda et.al. JACS 2004, 5356 ArNH O R OR2 R1 C6H4-p-NO2 catalyst O O O P OH Akiyama et.al. ACIE 2004, 1566 C6H4-p-NO2 Chiral Bronsted Acid Catalyzed Alkynylation of Imines N MeOOC R1 + H R2 5% AgOAc 10% catalyst Toluene H N R1 MeOOC up to 92% ee Ar catalyst = O O P O OH Ar Ar=9-phenanthryl Rueping et. al ACIE 2007,6903 R2 Proposed Mechanism O PHN OH R + R2 N R1 H O O R NH R2 P 1 H + R 1 N H H Cu(R3P) R3 (PR3)CuX + R2 N R1 R3 R3 Initial Attempt N H Ph + Ph p-Tol H 10% CuPF6(MeCN)2 CH2Cl2, r.t. 36h Ph N * p-Tol Ph a) no acid: 16% b) PhCO2H: 97% c) Fmoc N H 95%, 49% ee H CO 2 As pa Al rt i a c ac nin G e id l (O C uta bz lu ta min l) m ic e (X ac an id ) (O H ist bz id l) in e ( Is ol T s) eu ci n M et e* Ph hio en nin Th yla e re lan on in e in e Se (Bu rin t) e (B Ty zl) ro si ne Va lin Pr e ol in Pr e ol in e* Scanning of Amino Acids N p-Tol Ph + Ph H H Ph 10% CuPF6(MeCN)2 N 10% Amino acid p-Tol CH2Cl2, r.t. 16h * 70 60 50 40 % ee 30 20 10 0 Ph Proposed Mechanism O PHN OH R + R2 N R1 H O O R NH R2 P H + R 1 N H H (PR3)Cu R3 (PR3)CuX + N R1 R2 R3 R3 Tune the phosphine ligands could affect the enantioselectivity Scanning of Ligands N Ph + Ph p-Tol H 10% CuPF6(MeCN)2 H Ph 10% Amino acid N ligand * p-Tol CH2Cl2, r.t. 16h Ph L mol% L Yield (%) ee (%) PPh3 10% 95 71 PBu3 10% 78 80 P(OPh)3 10% 89 81 P(cyclohexyl)3 10% 92 81 P(1-Nap)3 10% 96 85 JohnPhos 10% 48 80 P(oTol)3 10% 96 88 P(oTol)3 20% 89 96 Diversity N R2 R1 + H HN 85% yield 95% ee Ligand=P(o-tolyl)3 R 3 2.5% CuPF6(MeCN)2 5% L 10% Boc-proline CH2Cl2 0 oC, 72h Cl * R2 R3 HN 87% yield 95% ee Ligand=P(o-tolyl)3 79% yield 99% ee Ligand=P(o-tolyl)3 HN Bn O nBu 78% yield 89% ee Ligand=P(c-hexyl)3 N R1 HN HN HN H 81% yield 92% ee Ligand=P(1-Nap)3 Ph 92% yield 93% ee Ligand=P(1-Nap)3 Lu, Y., Johnstone, T. C. Arndtsen, B. A. JACS, 2009, 11284 Pyrrole Synthesis R2 N R 1 R3 R5 R4 • Found in a wide range of natural products and pharmaceuticals • Antibacterial, antiviral (HIV-1), antiinflammatants, ntioxidants, cytokine inhibitors, etc. O Ph Ph N H N CH3 OCH3 F N N H OH HO2C SO2Et O CN N H F3C N Cl OEt OH Atorvastatin Br Antipsychotic Insecticide O O O N H Cl N Cl DNA cross-linking agent Existing Pyrrole Syntheses R1 R2 O + H2NR3 R2 R1 N R3 O Paal-Knorr Condensation N R3 CuI R1 R2 R2 N R3 R1 Gevorgyan JACS 2001, 123, 2074 S R1 R32CuLi S + R2 R4 NR5 R2 R1 N R5 R4 Luh JACS, 2000, 122, 4992 R2 R2 R1 R3 O O NC + EtO 2C R3 Ru4C O12 R1 N H CO2Et Murahashi Org Lett 2001, 3, 421 An Indole Synthesis Br + PPh3 N R O NaOMe Toluene relflux N R PPh3 + PPh3 PPh3 Base N R O N R O Le Corre,M; Hercouet, A; Le Baron, H. Journal of the Chemical Society, Chemical Communications 1981,1, 14-15. Idea Br PPh3 N O N R R R4 R3 R2 PPh3 R R2 N R1 O R1 R R1 + Cl N R N O R3 R2 R4 R3 R4 Syntheses of α,β Unsaturated Imines O R2 + R3 R4 O Base O R4 H Aldol R2 R3 R1NH2 α,β unsaturated imines can be prepared from simple starting materials N R4 R1 R2 R3 O R1NH2 + R2 R3 + O R4 H PPh3 O + R5 Cl R5 R4 R1 N R 2 R3 Proposal N R1 + R R2 R4 O O O N R Cl PPh3 R2 R4 R3 R1 R3 R R3 Ph3P N R1 R2 R4 Base O R1 N R2 R3 R R4 O=PPh3 R R3 Ph3P N R1 R2 R4 First Attempt N Me Ph Bn H 1.5 eq PPh3 2 eq NEt3 O + Cl NO2 H CH3CN r.t. O Bn N Me PNP Ph 71% + PNP N Ph PPh3 Me 20% O O 4 R Bn 1 N R3 R H R2 4 R N R3 R1 H 2 R Improvement by Tuning Counter Ion N Me Bn PPh3 2 eq NEt3 O H + Cl NO2 Ph CH3CN r.t. H Me Bn N PNP Ph Additives yields No 71% Bu4NI 86% Bu4NBr 78% NaI 52% KI 61% Pyrrole Synthesis 1 N R R 3 O 2 R + R5 Cl R4 Et N H Cl H Me N COOEt Me 1.5 eq. PPh3 Bu4NI 2 eq. Base CH3CN r.t. to 80 oC R2 R3 Ph N H R1 N NO2 R5 R4 OMe N H Et H S N 70% H 61% Et N S Me Bn N H Me NO2 82% H Et N 52% OEt Ph Et N H Me N 75% N 62% 59% CF3 Comparing with the method through Münchnone intermediate: No regioselectivety problem, Much more broader diversity 50% Synthesis of Lukianol A O OMe O PMP a) Toluene r.t. 2h H + PMP MeO H2N H O b) EtO2C Cl PPh3, DBU PMP DMB O N OEt a, b PMP H PMP O N OEt PMP 65 % c, d HO PMP = 4-MeOC6H4 DMB =2,4-(MeO)2C6H3 PMP N OH O HO O Lukianol A (a) anisol, TFA/CH2Cl2, 400C, 2h, 85%. (b) p-MeOC6H4COCH2Br, K2CO3, acetone, reflux, 92%. (c) (i) KOtBu,H2O, Et2O, 00C-rt; (ii) Ac2O, NaOAc, reflux (d) BBr3, CH2Cl2, -780C-rt, 63% (over two steps). Conclusion Amido esters and pyrroles. R1 R5 R2 N R 3 O Pd R1 R4 O R3 Pd N OR R2 R1 Pyrroles from Wittig reaction. R3 R4 Chiral NR1 O + R2 R5 Cl PPh3 R2 Base R3 R1 N R5 Bromsted acid. O OH + Substrate R NH P Chiral pool LnM R' Tunable catalyst R4 R3 N COOR R2 Synthesis of Secondary Amines: A Tandem Hydroboration-Aminaton Pathway The Steric-Royal Chemistry JACS, 2004, 126, 9200-9201. JACS 2009, 131, 5024-5025. Metal Catalyzed Amination R1 R2 NH2 + X Pd/BINAP NaOtBu m-xylene, 100oC R2 R1 N H J. Hartwig et. al. J. Am. Chem. Soc. 1994, 5969 S. L. Buchwald et. al. Angew. Chem. Inter. Ed. 1995, 1348 Though widely applied in organic synthesis, the harsh reaction condition and strong bases used limited the functionality tolerance An Alternative Route: Chan-Evans-Lam Reaction R1 B(OH)2 + R2 H N Cu(oAc)2/base R3 R1 DCE/r.t. R3 N R2 Lam, et. al. Tetrahedron Lett. 1998, 2941 Evans, et. al. Tetrahedron Lett. 1998, 2937 Chan, et. al. Tetrahedron Lett. 1998, 2933 Room temperature reaction with milder base Catalytic route with oxidant also been discovered Reactions involving alkyl boranes are rare, and require higher reaction temperature Reaction with Secondary Boranes Cu(oAc)2/base + BX2 NH2 N H slovent, r.t. Solvent bsae yield BF3K DCE K2CO3 5% BPin DCE K2CO3 75 %(at 90 0C) BCat DCE K2CO3 65% BCat benzene K2CO3 80% BCat benzene Cs2CO3 32% Boranes A One-Pot Hydroboration-Amination Pathway 1% Rh(COD)2BF4 2% DPPB + removal of solvent BCat HBcat THF, r.t. 1h BCat + NH2 2 eq. Cu(oAc)2 K2CO3 benzene, r.t. 8h N H 80% base on styrene Diversity R2 Rh cat. THF, r.t. Br H + ArNH2 R1 benzene, r.t. N 55% HN HN H N Cl 83% 85% O HN R1 Br O 72% 68% NO2 Cl HN H N HN HN O O O 62% 86% 64% NH R2 Cl Br H N Cu(oAc)2 K2CO3 R2 + HBCat R1 Ar BCat 52% O 56% But, No Retention of ee BCat Cu(OAc)2 K2CO3 + PhNH2 Ph NH benzene, r.t. 3% ee Changing solvent, adding ligands, varying temperature, etc Nothing helps. Switching to Another Strategy NHR2 Ar Cu cata./ chiral ligand BCat + Ar R1 R1 R2NH2 conditions BCat Ar But, I need a catalytic reaction condition R1 Searching for An Oxidant 20% Cu(OAc)2. BCat + PhNH2 Ph benzene, K2CO3, oxidant Oxidant Yield (%) AgOAc 21 O2 4 DDQ - tBuOOtBu 57 oxone - (PhCOO)2 50 NHPh Ph Ligands Screening 20% Cu(OAc)2. 24% ligand BCat + Ph PhNH2 NHPh * Ph benzene, K2CO3, (tBuO)2 ligand Yield ee R,R-DPEN - - R,R-pyBOX - - R,R-DACH - - Spartein 23 3 35 76 - - CF3 F3C MeN NMe S-MOP Conclusion Substituted amines could be synthesized from simple alkenes and primary amines through a tandem one-pot reaction Reaction proceeds under milder reaction conditions and with great functionality tolerance Asymmetric amination is still ongoing Acknowledgement Prof. Bruce Arndtsen Prof Cathleen Crudden The Arndtsen Group And The Crudden Group