EDF-Manchester_Modelling_Simulation

advertisement

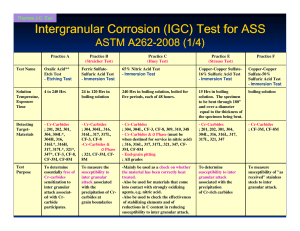

Materials Performance Centre Modeling Directions Crystal Plasticity Modeling Prediction of intergranular strains and mechanical properties • Relevant to stress corrosion cracking in stainless steels and Ni-base alloys • Good expertise in Manchester, validated by Xray and neutron diffraction • Need parallelization to allow larger microstructures and studies of permutations in reasonable timescales Grain Aggregate Modeling Prediction of intergranular stresses and strains • Relevant to stress corrosion, and intergranular damage mechanisms • Expertise developing in Manchester, using 3D microstructure data and diffraction-based validation • Need to validate modeling approaches and address issues due to large model size. Damage Modeling Prediction of microstructure effects on damage development • Relevant to stress corrosion cracking, for example • Development of current work on crystal aggregates, derived from tomography • Work done so far in partnership with other institutes • Need to develop further in Manchester Image-Based Modeling Dimensional Change of Graphite • Models constructed from tomography data, with crystal anisotropy deduced from pore orientations • Model validation against insitu tomography of thermal dimensional change • Aim to predict irradiation induced dimensional change • Currently limited by model size Image Based Modeling Issues • • • • How large a volume do you need to model? What resolution mesh do you need? As resolution of XMT systems improves, data sets and mesh sizes expand Research Needs Example: fibre composite Model – Development of visualisation methodologies – Development of serial mesh generation – Any size mesh (so far up to 320 GB data set) – Development of parallelised FE code – Development of XFEM Stress Development Grain Boundary Modeling Prediction of Diffusion and Segregation • Relevant to stress corrosion and sensitisation kinetics • Requires molecular dynamics methods • Currently little expertise in Manchester in this area, but development of capability is needed to support other work • Work being done with collaborators Flow Assisted Corrosion • Iron oxidation to give Fe(II) or magnetite Fe3O4 at the Cbulk 2+ internal metal-oxide interface Cs Fe Water 2+ Fe • Diffusion of soluble species • (Fe2+ and H2) across the porous Oxide layer 2+ Fe • Dissolution and reduction of 2+ magnetite into solution Fe C0 Oxide • Removal of the soluble iron species (and hydrogen), transported into the bulk of the flowing solution Steel FACrate K . .([ Fe 2 ] eq [ Fe 2 ]0 ) H2 H2 Other Areas • Multiscale modeling – Integration of microstructural models with fracture propagation models • Coupled modeling – Development of crack tip chemistry – Influence of residual stress on crack tip deformation