3. Digestion with Liquid Reagents

advertisement

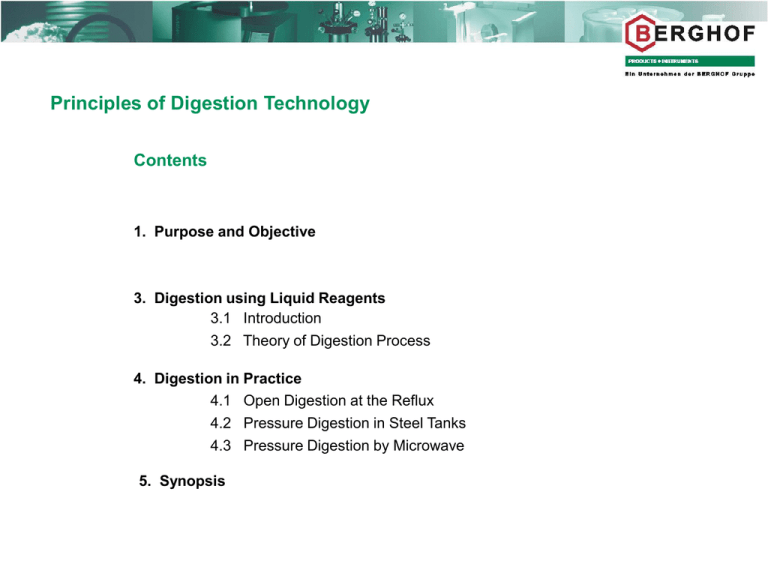

Principles of Digestion Technology Contents 1. Purpose and Objective 3. Digestion using Liquid Reagents 3.1 Introduction 3.2 Theory of Digestion Process 4. Digestion in Practice 4.1 Open Digestion at the Reflux 4.2 Pressure Digestion in Steel Tanks 4.3 Pressure Digestion by Microwave 5. Synopsis 1. Purpose and Objective Purpose Quantitative detection of elements in solids usually by subsequent spectroscopic analysis 1. Purpose and Objective Objective Clear dissolution of solid Complete destruction of matrix avoiding disturbances in subsequent analysis Avoidance of loss 3. Digestion with Liquid Reagents - Principle Chemical digestion of sample matrix Heating accelerates rate of reaction Max. temperature in open digestion limited by boiling point of solution Pressure build-up in closed vessels permits higher temperatures 3. Digestion with Liquid Reagents - General Aspects General procedure 1. Homogenisation of sample 2. Weigh-in of a representative aliquot 3. Addition of digestion reagent 4. Supply of energy (usually heat) 3. Digestion with Liquid Reagents - General Aspects Reagents Acid (e.g. with HCl, H2SO4...) Base (e.g. with NaOH, NH3...) Oxidising (e.g. with HNO3, H2O2, K2S2O8...) Reductive (e.g. with HJ, HBr...) Complexing agent (e.g. H3BO3...) 3. Digestion with Liquid Reagents - General Aspects Choice of reagents Organic matrices usually oxidising substances or mixtures (HNO3, H2O2, K2S2O8 and possibly H2SO4) Inorganic matrices usually mixtures with HNO3, HCl, (also aqua regia), HF and possibly H2SO4 pure metals: HCl, aqua regia, HCl/HF Oxides: H2SO4/HCl, H3PO4/HCl, mixtures containing HF 3. Digestion with Liquid Reagents - General Aspects Organic matrices - choice of reagents HNO3 (65%) Universally used For readily oxidisable samples (food, wood, fat, oil) Nitrate or nitrogen must not interfere with analysis Mixture of HNO3 (65%) / H2O2 (30%) approx. 4:1 Improved quality of digestion No improvement for samples that are difficult to digest (e.g. plastics) 3. Digestion with Liquid Reagents - General Aspects Organic matrices - choice of reagents Aqueous samples (waste water) Digestion with H2O2 (30%) / H2SO4 (1:1) mixture Difficult-to-digest samples (e.g. plastics) Digestion with HNO3 / H2SO4 (1:1) mixture Carbon in matrix made more readily corridible by dehydration Higher digestion temperatures due to lower vapour pressure of mixture 3. Digestion with Liquid Reagents - General Aspects Inorganic matrices - choice of reagents Pure metals Digestion with HCl, aqua regia or HCl / HF mixtures Oxides, including Al2O3 in particular Digestion in H2SO4 / HCl or H3PO4 / HCl or HF mixtures High proportion of high-boiling acid (approx. 80%) needed in order to achieve highest digestion temperatures at moderate pressures 3. Digestion with Liquid Reagents - Theory Digestion process - critical parameters Digestion temperature Digestion time Chemical potential of digestion reagents 3. Digestion with Liquid Reagents - Theory Digestion temperature High digestion temperatures shorter reaction time Digestion temperatures are limited by: vapour pressure of digestion acids temperature resistance of container/vessel materials pressure resistance of containers/vessels 3. Digestion with Liquid Reagents - Theory Pressure buildup in closed digestion Total pressure p p = p(CO2) + p(acid) p(CO2) p(acid) = partial pressure of CO2 produced = partial pressure of acid mixture CO2 pressure: dependent on carbon content of sample and weigh-in p(CO2) = 6.9 * mc [g] * T/V [K/ml] Example: V = 30 ml, 0.2 g carbon, 200°C p(CO2) = 22 bar V = 80 ml, 0.2 g carbon, 200°C p(CO2) = 8 bar 3. Digestion with Liquid Reagents - Theory Example (60 ml vessel at 200°C): 500 mg carbon develops 930 ml CO2 partial CO2 pressure of 26 bar Acid pressure for HNO3 at 200°C of approx. 10 bar Total pressure approx. 36 bar (60 ml vessel at 200°C) 3. Digestion with Liquid Reagents - Theory Vapour-pressure curves/graphs of pure acids a. Aqua regia b. HCl 36% c. HNO3 91% d. HCl 22.9% e. Water f. Boling point HNO3 100% g. Boiling point H2SO4 100% h. Boiling point H3PO4 96% (Panholzer, LaborPraxis, Oct. 1994, 32) T [°C] 3. Digestion with Liquid Reagents - Theory Digestion time Short digestion times recommended greater throughput of samples But good control of the process takes priority, e.g.: Slow heating in warm-up phase avoids spontaneous reactions Over-vigorous process control unnecessary wear and tear on material 3. Digestion with Liquid Reagents - Theory Chemical potential depends on Concentration of reagents employed in the solution Interaction of reagents Interaction of reagents with sample water Goal: The concentration of acids should not reduce greatly during digestion. 4. Practical Conduct of Digestion Open method at reflux Max. temperature limited by boiling point of acid mixture ( conc. H2SO4) Allows high weigh-ins Quality of digestion not always sufficient Loss of volatile elements (e.g. Hg, lead salts) 4. Practical Conduct of Digestion Pressure digestion in steel vessels Pressure resistance 200 bar Temperature max. 230°C (briefly 260°C) Digestion times from about 2 hours to several days Free from contamination due to PTFE-TFM lining Different internal volumes (25-250 ml) and therefore weigh-in quantities Outstanding quality of digestion No loss of volatile elements (e.g. Hg, lead salts) High degree of safety, easy operation 4. Practical Conduct of Digestion Pressure digestion in steel vessels - specimen application M a trix W e ig h -in A c id C e llu lo se /sta rch 1000 m g HNO3 1 6 0 °C 2h F lo u r/g ra in /le a ve s 1000 m g H N O 3 /H F 1 8 0 °C 2h T issu e /live r 1000 m g HNO3 1 7 0 °C -1 9 0 °C 2h F a t/o il 1000 m g H N O 3 (p o ss. H 2 O 2 ) 2 0 0 °C 4h P la stics 500 m g H N O 3 /H 2 S O 4 2 0 0 °C 3 -4 h C a rb o n /re sin 500 m g HNO3 2 2 0 °C 6h C e ra m ics/o xid e s 500 m g HF or HCl 2 3 0 °C 2 -8 h S te e l 500 m g H N O 3 /H C l 2 0 0 °C 4h Digestion Vessel DAB-3 (250 ml) T e m p e ra tu re T im e 4. Practical Conduct of Digestion Pressure digestion with microwave heating Pressure resistance dependent on type of container/vessel (40-100 bar) Free from contamination through use of PTFE-TFM containers Different interior volumes (10-100 ml) and therefore weigh-ins Quality of digestion mostly sufficient No loss of volatile elements (e.g. Hg, lead salts) High throughput of samples due to short digestion times (10-60 mins.) 4. Practical Conduct of Digestion Pressure digestion with microwave heating It is primarily the sample that is heated Container material (plastic) is only indirectly heated Relatively high digestion temperatures can be reached for short periods (30-40 minutes) 4. Practical Conduct of Digestion Container materials PTFE maximum 260º C PTFE-TFM maximum 260º C PFA maximum 200º C Quartz (silica) glass maximum 1,000º C (theoretically) 4. Practical Conduct of Digestion Temperature control The most important aspect of controlling microwave digestion Rate of reaction depends on temperature The temperature in the various vessels may vary as a function of the type of sample and the weigh-in quantity Temperature control is required in all vessels All samples can be subjected to non-contact IR temperature measurement speedwave MWS-3+ Temperature Control - Principle IR-measurement at wavelength, where TFM does not absorb IR-radiation Thermal radiation of the vessel is filtered out Heat radiation of vessel surface Heat radiation of sample TFM Mikrowave radiation IR-Sensor Filter IR-radiation 5. Synopsis Work in closed vessel wherever possible higher reaction temperature better quality of digestion Parameters determining digestion temperature, limited by: pressure resistance of container/vessel material of vessel Digestion in steel vessel for “most difficult samples” or lower sample throughput Digestion under microwave especially for high sample throughput