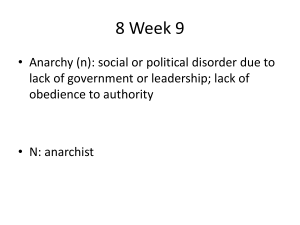

Material Selection

advertisement

RF9 Physics of Failure Sliding contact phenomena Material related failure RF9 Program Day 2 9:00-9:15 Introduction 9:15-9:30 Friction related failures 9:30-10:00 Demo load capacity of sliding contacts 10:00-10:15 Break 10:30-11:30 11:30-11:45 PoF Friction Application of gained results 11:45-12:30 PoF Wear 12:30-13:30 Lunch 13:30-14:00 Demo Dry Sliding and EP additives 14:00-15:00 PoF Material selection 15:00-15:15 Break 15:15-16:15 PoF Lubrication 16:15-16:45 Application of gained results 16:45-17:00 Summary of the day 2013 RF9 - Physics of Failure slide 2 Material & Coating Selection 2013 Adv Eng Design Page 222 RF9 - Physics of Failure – Material Selection slide 3 Case study Storm surge Barrier A movable storm surge barrier is constructed making dikes along the river unnecessary. 2013 Adv Eng Design Page 222 RF9 - Physics of Failure – Material Selection slide 4 Case study Storm surge Barrier F=35.000 Metric Tonnes Load m=15.000 Metric Tonnes Load p<150 MPa µ<0.1 Material selection ? 2013 Adv Eng Design Page 222 RF9 - Physics of Failure – Material Selection slide 5 Material & Coating Selection 7.1 Materials in relative sliding Metals, polymers, technical ceramics 7.2 Coatings and surface treatments Surface treatments and classification 7.3 Material selection Case study: storm surge barrier 2013 Adv Eng Design Page 222 RF9 - Physics of Failure – Material Selection slide 6 Material Selection: Metals steel, bronze, cast iron… 2013 Adv Eng Design Page 249 PF9 - Physics of Failure – Material Selection slide 7 Material Selection: Metals Why metal-metal combinations are always lubricated. Without lubrication: Without lubrication Severe adhesive friction / adhesive wear Metals of relative high hardness: + Relative good wear resistance (class 4) - High friction, scatter (µ=0.3...0.6) 2013 Adv Eng Design Page 249 Metals of relative low hardness: + Relative low friction (µ=0.08...0.14) - High wear rate (class 6) RF9 - Physics of Failure – Material Selection slide 8 Case 1 2013 Seminar - Physics of Failure slide 9 Material Selection: Metals How to reduce friction and wear due to adhesion Combinations of a non-metal against a metal Carburizing or nitriding High hardness of both surfaces Difference in hardness of a factor between 3 to 5 High roughness Strong oxide film Lubricant, liquid or solid Thin layer with low shear strength. 2013 Adv Eng Design Page 169 RF9 - Physics of Failure – Material Selection slide 10 Material Selection: Metals How to reduce friction and wear due to adhesion Combinations of a non-metal against a metal Carburizing or nitriding High hardness of both surfaces Difference in hardness of a factor between 3 to 5 High roughness Strong oxide film Lubricant, liquid or solid Thin layer with low shear strength. 2013 Adv Eng Design Page 169 RF9 - Physics of Failure – Material Selection slide 11 Material Selection: Polymers q Ff v F v q / A pv, A Ld Tc T0 q R pv Tc .m ax T0 RA µ(p,v) 2013 Adv Eng Design Page 209 Dependent on heat conduction RF9 - Physics of Failure – Material Selection slide 12 Material Selection: Polymers Polymers • Thermoplastics two types of thermoplastics - crystalline - amorphous • Thermosets cannot be reshaped by heating are stiff and strong in relation to thermoplastics are often reinforced with glass or carbon fibers • Elastomers rubbery polymers, can stretch easily and instantly return to its original shape when released. 2013 Adv Eng Design Page 309 RF9 - Physics of Failure – Material Selection slide 13 Material Selection: Polymers Thermoplastics + Do not need to be lubricated + Low weight + Injection molding - Low stiffness and strength - Mechanical properties strongly depend on temp - Poor heat conduction, large thermal expansion - Large machining tolerances 2013 Adv Eng Design Page 309 RF9 - Physics of Failure – Material Selection slide 14 Material Selection: Polymers 2013 Adv Eng Design Page 253 RF9 - Physics of Failure – Material Selection slide 15 Material Selection: Polymers Amorphous plastics + Less mold shrinkage - Susceptible to chemical attack - Lower wear resistance Crystalline plastics + Higher strength and rigidity + Higher wear resistance + Good chemical resistance to oils and grease (silicone based oils, water, soap…) 2013 Adv Eng Design Page 253 RF9 - Physics of Failure – Material Selection slide 16 Material Selection: Polymers price 2013 Adv Eng Design Page 257 RF9 - Physics of Failure – Material Selection slide 17 Material Selection: Polymers 2013 Adv Eng Design Page 261 RF9 - Physics of Failure – Material Selection slide 18 Material Selection: Polymers Self lubricating plastics are compounded with - PTFE, MoS2, Graphite, Silicone oil, Aramid fibres Fiber reinforced plastics are reinforced with - Glass fibers, Carbon fibers Steel counter surface - HRc>50, Ra=0.3-0.4 μm Aramid fibers - Improves resistance to abrasion especially against counter surfaces of lower hardness such as aluminum and plastics. 2013 Adv Eng Design Page 260 RF9 - Physics of Failure – Material Selection slide 19 Material Selection: Polymers 2013 Adv Eng Design Page 258, 261 RF9 - Physics of Failure – Material Selection slide 20 Case 2 Bronze St.50 (1.0050) Pmax=10…20 MPa Pmax=5…10 MPa Failure mode: 2013 Adv Eng Design Page 222 RF9 - Physics of Failure – Material Selection slide 21 Material Selection: Metals How to reduce friction and wear due to adhesion Combinations of non-metals or a non-metal against a metal Carburizing or nitriding High hardness of both surfaces Difference in hardness of a factor between 3 to 5 High roughness Strong oxide film Lubricant, liquid or solid Thin layer with low shear strength. 2013 Adv Eng Design Page 169 RF9 - Physics of Failure – Material Selection slide 22 Material Selection: Metals How to reduce friction and wear due to adhesion Combinations of non-metals or a non-metal against a metal Carburizing or nitriding High hardness of both surfaces Difference in hardness of a factor between 3 to 5 High roughness Strong oxide film Lubricant, liquid or solid Thin layer with low shear strength. 2013 Adv Eng Design Page 169 RF9 - Physics of Failure – Material Selection slide 23 Material Selection: Metals Difference in hardness of a factor between 3 to 5 Less tendency to adhesion (Pb, Sn) Good embed ability for abrasive particles Leveling out of stress concentrations 2013 Adv Eng Design Page 250 RF9 - Physics of Failure – Material Selection slide 24 Material Selection: Metals Main bearing Marine bearing 2013 Adv Eng Design Page 222 RF9 - Physics of Failure – Material Selection slide 25 Material Selection: Metals Elastic support Porous bearing Oil circulation within the pores 2013 Adv Eng Design Page 210 RF9 - Physics of Failure – Material Selection slide 26 Material Selection: Metals Porous iron 2013 Adv Eng Design Page 222 RF9 - Physics of Failure – Material Selection Hardened shaft slide 27 Material Selection: Metals Porous bronze (PbSn) bearings μ=0.06-0.10, k=0.3-0.9 10-15 m2/N, PV=1.75 106 Pa·m/s 2013 Adv Eng Design Page 222 RF9 - Physics of Failure – Material Selection slide 28 Case 3 2013 Adv Eng Design Page 306, 35, 221 RF9 - Physics of Failure – Material Selection slide 29 Material Selection: Metals How to reduce friction and wear due to adhesion Combinations of non-metals or a non-metal against a metal Carburizing or nitriding High hardness of both surfaces Difference in hardness of a factor between 3 to 5 High roughness Strong oxide film Lubricant, liquid or solid Thin layer with low shear strength. 2013 Adv Eng Design Page 169 RF9 - Physics of Failure – Material Selection slide 30 Material Selection: Metals How to reduce friction and wear due to adhesion1) : Combinations of a non-metal against a metal Carburizing or nitriding Layered molecular High hardness of both surfaces structure of graphite Difference in hardness of a factor between 3 to 5 High roughness Strong oxide film Stainless Lubricant, liquid or solid steel Thin layer with low shear strength Thin oxide layer Stainless steel bolts require special purpose lubricants 2013 Adv Eng Design Page 169 RF9 - Physics of Failure – Material Selection slide 31 AF-Coating (MoS2, graphite) Case 3 Layered molecular structure of graphite Successful application in clearance fits to prevent fretting corrosion (left) or galling (right) 2013 Adv Eng Design Page 306, 35, 221 RF9 - Physics of Failure – Material Selection slide 32 Material Selection: Metals AF-Coating, P>100MPa, µ<0.1 Particle orientation after initial sliding Layered molecular structure of graphite AF-Coating (MoS2, graphite) Successful application in screw joints 2013 Adv Eng Design Page 306 RF9 - Physics of Failure – Material Selection slide 33 Material Selection: Metals Layered molecular structure of graphite 2013 Adv Eng Design Page 309 RF9 - Physics of Failure – Material Selection slide 34 Material Selection: Metals How to reduce friction and wear due to adhesion1) : Combinations of non-metals or a non-metal against a metal Carburizing or nitriding High hardness of both surfaces Difference in hardness of a factor between 3 to 5 High roughness Galvanized Strong oxide film Lubricant, liquid or solid Thin layer with low shear strength High corrosion resistance 2013 Adv Eng Design Page 169 RF9 - Physics of Failure – Material Selection slide 35 Material Selection: Metals How to reduce friction and wear due to adhesion Combinations of a non-metal against a metal Carburizing or nitriding High hardness of both surfaces Difference in hardness of a factor between 3 to 5 High roughness Strong oxide film Lubricant, liquid or solid Thin layer with low shear strength. 2013 Adv Eng Design Page 169 RF9 - Physics of Failure – Material Selection Case 4 slide 36 Material Selection: Tech. Ceramics Al2O3 SiC Si3N4 ZrO2 ZTA = Alumina = Silicon Carbide = Silicon Nitride = Zirconia = Zirconia Toughened Alumina + High hardness and wear resistance + Low specific weight + Excellent high temperature properties + Resistance to corrosive environment - Low toughness (brittle) 2013 Adv Eng Design Page 267 RF9 - Physics of Failure – Material Selection slide 37 Material Selection: Tech. Ceramics 2013 Adv Eng Design Page 151 RF9 - Physics of Failure – Material Selection slide 38 Material Selection: Tech. Ceramics + High resistance to abrasive wear (elastic deformation) + High resistance to adhesive wear (small γ/H ratio) High surface energy but small ratio of surface energy and hardness 2013 Adv Eng Design Page 151 ~H 1/3 RF9 - Physics of Failure – Material Selection slide 39 Material Selection: Tech. Ceramics Hydrodynamic bearing operating in abrasive environment (Pavg= 6 MPa) 2013 Adv Eng Design Page 266 RF9 - Physics of Failure – Material Selection slide 40 Material Selection: Tech. Ceramics Jewel bearings Industrial jewels Diamond pivots 2013 Adv Eng Design Page 504, 523 RF9 - Physics of Failure – Material Selection slide 41 Case 5 2013 Adv Eng Design Page 169 RF9 - Physics of Failure – Material Selection slide 42 Material Selection: Metals How to reduce friction and wear due to adhesion Combinations of non-metals or a non-metal against a metal Carburizing or nitriding High hardness of both surfaces Difference in hardness of a factor between 3 to 5 High roughness Strong oxide film Case 5 Lubricant, liquid or solid Thin layer with low shear strength. 2013 Adv Eng Design Page 169 RF9 - Physics of Failure – Material Selection slide 43 Material Selection: Coatings & surface treatments Bonding strength 2013 Adv Eng Design Page 269 RF9 - Physics of Failure – Material Selection slide 44 Material Selection: Coatings & surface treatments 2013 Adv Eng Design Page 270 RF9 - Physics of Failure – Material Selection slide 45 Material Selection: Coatings & surface treatments Advantage of dissimilar materials (Metallurgical incompatible materials). 2013 Adv Eng Design Page 268 RF9 - Physics of Failure – Material Selection slide 46 Material Selection Introducing residual compressive stresses up to half the yield strength in order to improve the fatigue strength. Laser peening imparts a layer of compressive stress that is four times deeper than that attainable from conventional shot peening 2013 Adv Eng Design Page 273 RF9 - Physics of Failure – Material Selection slide 47 Material Selection: Coatings & surface treatments 2013 Adv Eng Design Page 268 Nickel and chromium plating PF9 - Physics of Failure – Material Selection slide 48 Material Selection: Coatings & surface treatments Laser cladding Laser cladding is an effective way to refurbish and improve worn or damaged industrial components 2013 Adv Eng Design Page 268 RF9 - Physics of Failure – Material Selection slide 49 Material Selection: Coatings & surface treatments Pre-machining: removal of worn and with lubricant diffused material Substrate low alloyed C-steel, Clad material Stellite 21 Post-machining to required dimensions 2013 Adv Eng Design Page 273 RF9 - Physics of Failure – Material Selection slide 50 Material Selection: Coatings & surface treatments HVOF Spraying Al2O3 TiO2 WC 2013 Adv Eng Design Page 270 RF9 - Physics of Failure – Material Selection slide 51 Material Selection: Coatings & surface treatments CVD -TiN 2013 Adv Eng Design Page 273 RF9 - Physics of Failure – Material Selection slide 52 Material Selection: Coatings & surface treatments 2013 Adv Eng Design Page 274 RF9 - Physics of Failure – Material Selection slide 53 Material Selection: Coatings & surface treatments Adhesive wear (Galling) DLC coatings in sheet metal forming, µ<0.1 2013 Adv Eng Design Page 268 RF9 - Physics of Failure – Material Selection slide 54 Material Selection: Coatings & surface treatments 2013 Adv Eng Design Page 275, 276 RF9 - Physics of Failure – Material Selection slide 55 Material Selection: Coatings & surface treatments Summary • The wear resistance of a machine part + hard surface is determined by the wear resistance + tough core of it’s surface. • This means that for the surface other demands can be made than for the bulk material • There are plenty of options to improve the surface quality • Treatments in the surface / on the surface 2013 Adv Eng Design Page 275, 276 RF9 - Physics of Failure – Material Selection slide 56 Half of the Netherlands is below Case study Storm surge Barrier sea level. To prevent flooding dikes along the coast line are raised to delta level. Raising the dikes along the river are unwanted and would be very expensive. A dam isn’t possible while the seaport of Rotterdam must remain accessible. Adv Eng Design Page 275, 276 Adv Eng Design Page 275, 276 Adv Eng Design Page 275, 276 Adv Eng Design Page 275, 276 Adv Eng Design Page 275, 276 Adv Eng Design Page 275, 276 Adv Eng Design Page 275, 276 Adv Eng Design Page 275, 276 Adv Eng Design Page 275, 276 Adv Eng Design Page 275, 276 Adv Eng Design Page 275, 276 Case study Storm surge Barrier F=35.000 tonnes m=15.000 tonnes p<150 MPa µ<0.1 Material selection ? 2013 RF9 - Physics of Failure – Material Selection slide 68 Case study Storm surge Barrier The allowable pressure in sliding contacts between metals is limited by seizure Steel – cast iron 5…10 MPa, μ=0.12…0.18 Steel - CuSn or CuAl alloys 10…20 MPa, μ=0.12…0.18 In screw joints contact pressures up to 100 MPa are common, but the sliding motion is limited to one single move and μ=0.12…0.18 2013 Zinc plated to prevent corrosion and seizure. RF9 - Physics of Failure – Material Selection slide 69 Solid lubricants AF-Coating, P>100MPa, µ<0.1 Particle orientation after initial sliding Layered molecular structure of graphite AF-Coating (MoS2, graphite) Successful application in screw joints 2013 Adv Eng Design Page 306 RF9 - Physics of Failure – Material Selection slide 70 Case study Storm surge Barrier Solid lubricants are used for conditions where conventional lubricants are inadequate Reciprocating motion, fretting Improvement of running in conditions Extreme contact pressures Shock loading High temperatures Ceramics 2013 Adv Eng Design Page 309 RF9 - Physics of Failure – Material Selection slide 71 Case study Storm surge Barrier P<150MPa, µ<0.1 2013 Adv Eng Design Page 307 PF9 - Physics of Failure – Material Selection slide 72 Case study Storm surge Barrier What to do? High maintenance costs Adhesive wear between casting steel parts How to prevent failure µ>0.1? 2013 RF9 - Physics of Failure – Material Selection slide 73 Case study Storm surge Barrier The problem: High maintenance costs (wear by seizure) The challenge: Find a tribo system (material combination) that sustains high contact pressures in sliding motion and show minimal friction and minimal wear. The solution: ? 2013 RF9 - Physics of Failure – Material Selection slide 74 Case study Storm surge Barrier The solution: ? Only limited possibilities to modify the realized construction. 2013 Alternative lubricant or coating system? Boundary Lubricated metal - metal contacts p<20MPa, µ>0.1 Thermoset – metal contacts p<150 MPa, µ>0.1 Polymer – metal contacts p<10 MPa, µ<0.1 RF9 - Physics of Failure – Material Selection slide 75 Case study Storm surge Barrier Coulombs law: If the load is doubled the friction is doubled. Not for polymers! Polymer – metal contacts only for limited contact pressure? 2013 RF9 - Physics of Failure – Material Selection slide 76 Case study Storm surge Barrier Cast steel with epoxy coating UHMWPE Cast steel Carbon fiber PE against epoxy resin, p>150 MPa, µ=0.02…0.06 F > 7000 kN (700 tonnes). 2013 RF9 - Physics of Failure – Material Selection slide 77 Case study Storm surge Barrier 2013 PF9 - Physics of Failure cutter – Material Selection Testing of a special engineered turning slide 78 2013 RF9 - Physics of Failure – Material Selection slide 79 500 holes in each ball joint 2013 RF9 - Physics of Failure – Material Selection slide 80 2013 PF9 - Physics of Failure – Material Selection slide 81 Case study Storm surge Barrier Summary The problem: High maintenance costs (wear by seizure) The solution: Polymer discs, expansion blocked by carbon fiber rings, sliding against epoxy coated steel surface. Performance: Contact pressures up to 150 MPa, coefficient of friction μ < 0.05, lifetime > 5 km sliding distance, maintenance limited to overhauling of the epoxy coating after a large number of moves. 2013 RF9 - Physics of Failure – Material Selection slide 82 Material Selection Summary • Several different material combinations have been discussed with respect to their applications. • Metals, metal alloys, thermoplastics, thermosets, ceramics and many coatings or surface treatments. • There is not an ideal material combination for sliding contacts in general. • In machine design metal-metal combinations are common and it is demonstrated that these combinations need to be lubricated. 2013 RF9 - Physics of Failure – Material Selection slide 83 RF9 Program Day 2 9:00-9:15 Introduction 9:15-9:30 Friction related failures 9:30-10:00 Demo load capacity of sliding contacts 10:00-10:15 Break 10:30-11:30 11:30-11:45 PoF Friction Application of gained results 11:45-12:30 PoF Wear 12:30-13:30 Lunch 13:30-14:00 Demo Dry Sliding and EP additives 14:00-15:00 PoF Material selection 15:00-15:15 Break 15:15-16:15 PoF Lubrication 16:15-16:45 Application of gained results 16:45-17:00 Summary of the day 2013 RF9 - Physics of Failure slide 84