Non-Li battery materials

advertisement

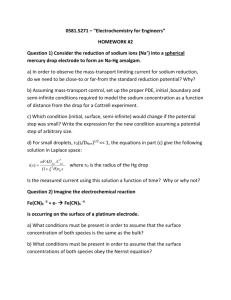

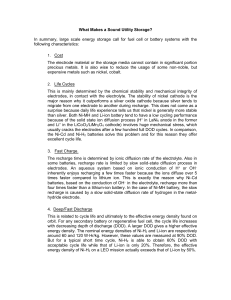

SODIUM SULFUR BATTERIES Elisa Zaleski MAT 286G Final May 26, 2010 BATTERY BASICS • A chemical reaction produces electrons – Electrons travel from the (-) to the (+) electrode – Ions travel through the electrolyte • “Anode” = from the Greek for “way up” – Current flows through the anode into the device • Discharging? Negative electrode • Charging? Positive electrode • “Cathode” = from the Greek for “way down” – Current flows through the cathode out of the device • Discharging? Positive electrode • Charging? Negative electrode CURRENT: NAMING THE ANODE AND CATHODE N Cathode (Negative W Electrode) “Way Down” Current Electrolyte Anode (Positive E Electrode) “Way Up” S Electrolytic Cell (Recharging) NAS: THE BASICS • Liquid sodium and liquid sulfur as the negative and positive electrodes • Solid ceramic as the Na+ conducting electrolyte – β-alumina – NaSICON (Na Super Ionic CONductor) • Operating temperature ≅ 300oC (to maintain the electrodes in the liquid state) • Potential Applications: – Electric vehicles • Ford Ecostar 1991 – Energy storage www.greencar.com/articles/ford-ecostar-ev.php NAS: THE BASICS • Key Features: – High-energy density (~367Wh/l) with a reduction in space required for the battery – EMF ~ 2V – No self-discharge – High cycle life • 40,000+ cycles at 20% depth of discharge (DOD) • 4,500 cycles to 90% DOD • 2,500 cycles to 100% DOD – Sodium and sulfur are relatively abundant NAS: THE CONSTRUCTION • Solid electrolyte separates the sodium inner core from the sulfur annulus • Protective Fe-75Cr coating is plasma sprayed on the inner wall to avoid corrosion • Configured in series and parallel Image courtesy of NASA Glenn Research Center NAS: THE CHEMISTRY 2Na + xS Na2Sx Discharge Charge • Na (negative electrode) sends electrons through the circuit • Na+ pass through the electrolyte • Na+ reacts with S to form sodium polysulfides at the positive electrode • Sodium polysulfides decompose • Na+ passes back through the electrolyte DISCHARGE CYCLE Oshima, Kajita, and Okuno, Int. J. Appl. Ceram. Technol., 1 [3] 269-76 (2004) CHARGE CYCLE Oshima, Kajita, and Okuno, Int. J. Appl. Ceram. Technol., 1 [3] 269-76 (2004) POLYSULFIDE VERSUS VOLTAGE • The polysulfide formed changes with state-of-charge – At ~Na2S2 it is at full discharge Oshima, Kajita, and Okuno, Int. J. Appl. Ceram. Technol., 1 [3] 269-76 (2004) TRANSPORTING NA+: β-ALUMINA • Na2O(5-11)Al2O3 – NaAl11O17 – Non-stoichiometric compound of Na2O and Al2O3 that includes β and β” • β” = Na2O(5-7)Al2O3 – MgO added to increase the stability at the high sintering temperatures • ‘Spinel’ layers separated by conduction planes Oshima, Kajita, and Okuno, Int. J. Appl. Ceram. Technol., 1 [3] 269-76 (2004) TRANSPORTING NA+: NASICON • Superior Na+ conductivity compared to β-alumina • Na1+xSixZr2P3-xO12 (0<x<3) • 3D network of ZrO6 octahedra sharing corners with PO4 and SiO4 tetrahedra • Na+ located in interstitial sites • Mainly monoclinic NASICON Housecroft and Sharpe, Inorganic Chemistry, 3rd Edition 2008 NASICON VS β-ALUMINA Housecroft and Sharpe, Inorganic Chemistry, 3rd Edition 2008 NAS BATTERIES: TAKING US OFF THE GRID? BATTERIES: STORING ENERGY http://www.npr.org/templates/story/story.php?storyId=110997398 NAS BATTERIES: TAKING US OFF THE GRID? • Ceramatec is developing a low temperature (<100oC) solid NaS battery using a NaSICON electrolyte designed for home energy storage – Prototype due out 2011 • Potential Specs – 20kWh – Daily charge/discharge cycles over 10 years – $2000 per refrigerator sized unit • $100/kWh or <$0.03/kWh over the battery’s lifetime • Grid storage market expected to increase from $365 million today to ~$2.5 billion by 2015