Introduction to Rheology

Complex Fluids with

Applications to Biology

2011/2012 VIGRE RFG

Rheology

•

Study of deformation and flow of matter

•

Classical fluids quickly shape themselves into a container and classical solids maintain their shape indefinitely

– Intuitively, a fluid flows, and a solid does not!

–

Newtonian fluids have constant viscosity

–

Stress depends linearly on the rate of strain

•

Complex fluids may maintain their shape for some time, but eventually flow

–

Viscosity depends on applied strain

– Stress is nonlinear function of rate of strain

–

Properties may include

•

Shear thinning / thickening (e.g. paint / cornstarch in water)

•

Normal stresses – (leads to rod climbing for example)

• “Elastic turbulence” - low Reynolds number flows

Examples of Complex Fluids

•

Foods

–

Emulsions (mayonnaise, ice cream)

–

Foams (ice cream, whipped cream)

– Suspensions (mustard, chocolate)

–

Gels (cheese)

•

Biofluids

–

Suspension (blood)

– Gel (mucin)

–

Solutions (spittle)

•

Personal Care Products

–

Suspensions (nail polish, face scrubs)

– Solutions/Gels (shampoos, conditioners)

–

Foams (shaving cream)

•

Electronic and Optical Materials

–

Liquid Crystals (Monitor displays)

– Melts (soldering paste)

•

Pharmaceuticals

–

Gels (creams, particle precursors)

–

Emulsions (creams)

– Aerosols (nasal sprays)

•

Polymers

Granular Flows

A goal of Rheology

Establishing the relationship between applied forces and geometrical effects induced by these forces at a point (in a fluid).

–

The mathematical form of this relationship is called the rheological equation of state, or the constitutive equation.

–

The constitutive equations are used to solve macroscopic problems related to continuum mechanics of these materials.

–

Equations attempt to model physical reality.

Different theories are appropriate for different problems

•

Continuum theories

–

Cornerstone of traditional fluid mechanics

•

Material is treated as a continuum, consider objects such as velocity, acceleration, stress at a point

•

So-called constitutive models give continuum description of stress

•

Stress may have many degrees of freedom depending on material composition

•

Limitations in model

•

Useful for straightforward solutions (relatively speaking – numerical, analytical…)

•

Multi-scale

–

Can be more flexible

•

Material may have small scale fluctuations which can be modeled directly

•

Need to communicate between levels

•

Computationally challenging

Rheological Properties

•

Stress

–

Shear stress

–

Normal stress

–

Normal Stress differences

•

Viscosity

–

Steady-state (i.e. shear)

–

Extensional

–

Complex

•

Viscoelastic Modulus

–

G

’ – storage modulus

–

G

” – loss modulus

•

Creep, Compliance, Decay

•

Relaxation times

• and many more …

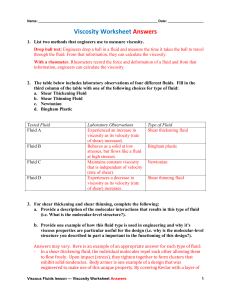

Common Non-Newtonian Behavior

• shear thinning

• shear thickening

• yield stress

• viscoelastic effects

–

Weissenberg effect

–

Fluid memory

–

Die Swell

Shear Thinning and Shear Thickening

• shear thinning – tendency of some materials to decrease in viscosity when driven to flow at high shear rates , such as by higher pressure drops

Increasing shear rate

Shear Thickening

• shear thickening

– tendency of some materials to increase in viscosity when driven to flow at high shear rates

Yield Stress

•

Tendency of a material to flow only when stresses are above a threshold stress

•

Eg. Ketchup or Mustard

Elastic and Viscoelastic Effects

•

Weissenberg Effect (Rod Climbing Effect)

– does not flow outward when stirred at high speeds

Elastic and Viscoelastic Effects

•

Fluid Memory

–

Conserve shape over time periods or seconds or minutes

–

Elastic like rubber

–

Can bounce or partially retract

–

Example: clay (plasticina)

Elastic and Viscoelastic Effects

•

Viscoelastic fluids subjected to a stress deform

– when the stress is removed, it does not instantly vanish

– internal structure of material can sustain stress for some time

– this time is known as the relaxation time, varies with materials

– due to the internal stress, the fluid will deform on its own, even when external stresses are removed

– important for processing of polymer melts, casting, etc..

Elastic and Viscoelastic Effects

Die Swell

– as a polymer exits a die, the diameter of liquid stream increases by up to an order of magnitude

– caused by relaxation of extended polymer coils, as stress is reduced from high flow producing stresses present within the die to low stresses, associated with the extruded stream moving through ambient air

Viscoelastic fluid – Elastic “turbulence” - Efficient mixing

(Low Re, “High” Wi) Groisman & Steinberg

Rotating plates

Mixing in micro channels

Arratia and Gollub et al., PRL 2006

Elastic fluid instabilities near hyperbolic points

Basic continuum and multi-scale models

•

Conservation of mass

t

(

u )

0

•

Conservation of momentum

( t u u u )

g

•

Cauchy stress tensor :

( , )

F t x

u t x

( , )

Deformation

( , ( , ))

x

X

Deformation gradient

•

Basic continuum and multi-scale models

Viscoelastic Fluid – dilute solution of polymer chains in a Newtonian solvent spring

End to end vector

R

Polymer moves via Brownian motion in fluid bead Smoluchowski equation gives evolution of probability density in phase space

¶ t y + Ñ

R

×

( y

R )

=

0 m i

Force on ith bead: s i

= x i

( s i

u i

)

kT

¶

¶ s i ln y +

F i

Stress:

s

p

Solvent Stress Polymer Stress

Polymer stress:

P

F R

C RR

T

Assume linear

Hooke ’ s law for bead forces

s

p I+2

s

E

Incompressible fluid

p

(

p

G I)=0

Relaxation time

Evolution of polymer stress

Thermodynamic constant

t

u

( u

u

T

)

Upper convected derivative

Oldroyd-B equations

( t u u u ) p

s u

p

p

(

p

G I)

0 f

0

Scale of nonlinear terms to relaxation term is given by the dimensionless parameter

( / )

Weissenberg number

Complex Fluids, an overview

Some references:

• Dynamics of Polymeric Liquids, Vol. I and II , Bird, Armstrong,

Hassager, Wiley, 1987

• The Structure and Rheology of Complex Fluids , R. Larson,

Oxford U. Press, 1999

• Computational Rheology , R. G. Owens and T. N. Phillips,

Imperial College of London Press, 2002

• Mathematical Problems in Viscoelasticity , M. Renardy, W.

Hrusa, J. Nohel, Pitman Monographs and Surveys in Pure and

Applied Mathematics 35, Longman 1987

• An Introduction to Continuum Mechanics, M. E. Gurtin, volume

158 of Mathematics of Science and Engineering, Academic

Press, 1981