IIT, Mumbai - CASDE

advertisement

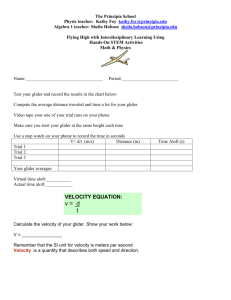

Introduction Sir George Cayley Conventional configuration Otto Lilienthal Airfoil data, first pilot Alphonse Penaud Rubber powered models Octave Chanute Pratt truss Wright Brothers Control centric approach Wing warping for roll control First wind tunnel tests Adverse yaw Canard for pitch control The Wright approach Wing warping tested on 1899 kite 1901 glider was a disappointment Wind tunnel testing leads to 1902 glider First powered flight, 1903 Problems in replication Instability Pitch, CG behind NP Spiral mode, Anhedral Control Smaller tail volumes Constructional Practical limits due to scaling down Strategy S ta rt E xp lo re A irp la n e th ro u g h lite ra tu re s u rve y B u ild G lid e rs P re lim R e p o rt, A p r 2 0 0 2 M ay 2002 P ro p u ls io n G lid e r T e s tin g F in a l D e s ig n , N o v 2 0 0 2 D e ta ile d R e p o rt, D e c 2 0 0 2 M odel Backup M odel F lig h t te s tin g , J u n e 2 0 0 3 D one, N ov2003 Strategy Exploring a/c Literature study Proposed solutions Making gliders Material selection Practical limits on fabrication Implementation of control mechanisms Propulsion Market survey for Contra-rotating pushers Belts, pulleys and shafts Engine Test the setup Glider Specifications 1:12 scaled down model Wing Span 1.02 m Length 0.54m Canard area 6.3% of wing area, 0.0210 m2 Rudder area 0.01 m2 Weight 0.15 Kg Ballast weight 0.040 Kg Wing loading 0.11 kg/m2 Glider Glider Experience Material selection Central carbon fibre box supporting Wing Canard and rudder Engine Landing gear Central Box Glider Experience Material selection Balsa wood used for Wing ribs Canard and rudder Vertical struts Glider Experience Monokote for wing covering Slotted ribs for front spar Joints Strut-spar pin joints replicated Pins lashed to spars and struts Rigging with twine thread View of joints Glider Experience Controls Steel wire for wing warping Flexible joints in rear spar for wing warping Complete canard moved for pitch control (unlike original variable camber) Weight estimation Controls part 4 servos + Receiver+ Battery pack + Miscellaneous 160gm + 30gm + 120gm + 50gm =360 gm Propulsion part Engine + Mount + Shafts, Belts, Pulleys + Fuel + Misc 335gm + 150gm+ 300gm+ 250gm+ 65gm =1100 gm Landing gear = 150gm Structure part Carbon fiber composite + Balsa + Misc 450gm + 300gm + 250gm =1000gm Total Maximum weight = 3 kg Wing loading with this weight = 0.338 kg/m2 Thrust and Power Estimation Max thrust required at min Cl/Cd = 12 N Power required at this Cl/Cd is 120 W Engine of 250 W at 16000 rpm Two 10X6 props at 8000 rpm give 15 N thrust -12 2 4 Thrust in lbs = 2.83x10 x RPM x D x Cp x (P/29.92) x (528/(460+T)) Propulsion Electric motor Less weight No starting problems Ease of maintenance Large battery weight (Can be used as ballast) Lesser heating problems Propulsion Wankel IC engine High power Less fuel weight Cooling problems ? Propulsion Belt pulley system Propeller shaft mounting replicated Contra-rotating propellers ? Side view transmission system 9.3 cm 4 cm 11 cm 6 cm 25 cm Front View 23.5 cm 12 cm 5 cm 39.4 cm Unsolved problems Roll-yaw coupling ? Asymmetric yawing moment ? Pitch SAS using rate gyro? Tail and canard volumes ? Anhedral ? Landing ? Twisted belt drive ? Cost Estimate Carbon fibre 2000 Balsa 500 Engines 8000 Belt, Pulleys, Bearings, Propeller Servos 2900 Miscellaneous 500 Total 17,900 4000 Acknowledgements Prof. K. Sudhakar, IIT Bombay Dr. H. Arya, IIT Bombay