Force Sensing Resistors

advertisement

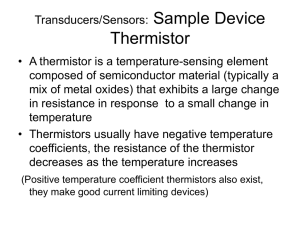

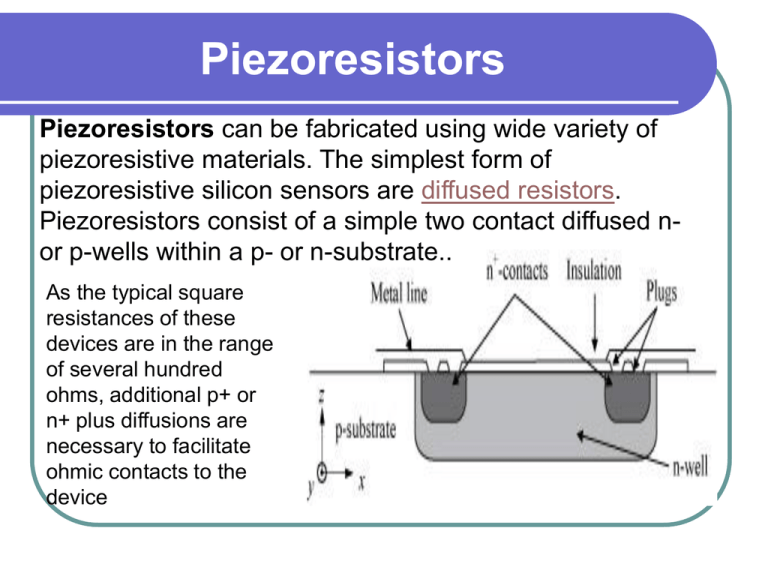

Piezoresistors Piezoresistors can be fabricated using wide variety of piezoresistive materials. The simplest form of piezoresistive silicon sensors are diffused resistors. Piezoresistors consist of a simple two contact diffused nor p-wells within a p- or n-substrate.. As the typical square resistances of these devices are in the range of several hundred ohms, additional p+ or n+ plus diffusions are necessary to facilitate ohmic contacts to the device Physics of operation www.stanford.edu/ Signal analyzer Cantilever Calibration Laser vibrometer Vdisplacemen t 15V Vstrain Piezoresistor Bridge Voltage vs. Displacement Measure at resonant frequency of cantilever Typical sensitivity ~ 1mV/µm Noise spectrum of piezoresistor < 0.1µV/Hz or ~80pN/ Hz at 1Hz Force Sensing Resistors As their name implies, force sensing resistors use the electrical property of resistance to measure the force (or pressure) applied to a sensor. A force sensing resistor is made up of two parts. The first is a resistive material applied to a film. The second is a set of digitating contacts applied to another film. Figure shows this configuration. The resistive material serves to make an electrical path between the two sets of conductors on the other film. When a force is applied to this sensor, a better connection is made between the contacts, hence the conductivity is increased. switches using FSRs. Above this region, the force is approximately proportional to until a saturation region is reached. When forces reach this magnitude, additional forces do not decrease the resistance substantially Piezoresistive for pressure Piezoelectric pressure sensors: As active designs, piezoelectric sensors can only be used for quasistatic rather than truly static measurement. However they are ideal for dynamic applications. Piezoelectric pressure sensors can be employed wherever rapidly changing pressures at temperatures of up to 400°C have to be measured as accurately as possible Piezoresistive for pressure The piezoresistive principle is based on the semiconductor effect first described in 1954, which states that under mechanical stress semiconductors change their electrical resistance. Compared with the conventional strain gage measurement of the time, this opened up completely new applications. Since then similar breakthroughs have included the thin film technique on metal and its thick layer counterpart on ceramic. Piezoresistive sensors measure static pressures in gases and liquids. The results achieved under even the most adverse conditions are precise and repeatable. Photo-electric sensors For non-contact detection of targets at a distance regardless of material. Photoelectric sensors emit invisible infrared or visible red light to detect the presence of an object. The target either breaks a beam of light or reflects it back to the detector to activate the sensor output Photo-electric sensors Advantages of photoelectric sensors include longer standoff distances than inductive proximity sensors, ability to detect virtually any target material, ability to differentiate between targets of different color or surface characteristics, and the ability to operate in different sensing modes such as thru-beam, retroreflective, or diffuse Photo-electric sensors Counting Product Counting a Product on the Conveyor Belt, while numbers of interruptions of light are counted electronically with the help of electronic circuits coupled with sensors. Thermistor A thermistor is a type of resistor whose resistance varies with temperature. Thermistors are widely used as inrush current limiters, temperature sensors, self-resetting overcurrent protectors, and self-regulating heating elements Thermistors differ from resistance temperature detectors (RTD) in that the material used in a thermistor is generally a ceramic or polymer, while RTDs use pure metals. The temperature response is also different; RTDs are useful over larger temperature ranges, while thermistors typically achieve a higher precision within a limited temperature range [usually -90C to 130C] Basic operation of Thermistor Assuming, as a first-order approximate that the relationship between resistance and temperature is linear, then: ΔR = k.ΔT where ΔR = change in resistance ΔT = change in temperature k = first-order temperature coefficient of resistance Types of Thermistor Thermistors can be classified into two types depending on the sign of k. If k is positive, the resistance increases with increasing temperature, and the device is called a positive temperature coefficient (PTC) thermistor, or posistor. If k is negative, the resistance decreases with increasing temperature, and the device is called a negative temperature coefficient (NTC) thermistor. Resistors that are not thermistors are designed to have a k as close to zero as possible, so that their resistance remains nearly constant over a wide temperature range Applications of NTC NTC thermistors are used as resistance thermometers in lowtemperature measurements of the order of 10 K. NTC thermistors can be used as inrush-current limiting devices in power supply circuits. They present a higher resistance initially which prevents large currents from flowing at turn-on, and then heat up and become much lower resistance to allow higher current flow during normal operation. These thermistors are usually much larger than measuring type thermistors, and are purposely designed for this application. NTC thermistors are regularly used in automotive applications. For example, they monitor things like coolant temperature and/or oil temperature inside the engine and provide data to the ECU and, indirectly, to the dashboard. Thermistors are also commonly used in modern digital thermostats and to monitor the temperature of battery packs while charging. Applications of PTC PTC thermistors are temperature dependent resistors manufactured from barium titanate and should be chosen when a drastic change in resistance is required at a specific temperature or current level. PTCs can operate in the following modes: Temperature sensing, switching at temperatures ranging from 60°C to 180°C, e.g. protection of windings in electric motors and transformers. Solid state fuse to protect against excess current levels, ranging from several mA to several A (25°C ambient) and continuous voltages up to 600V and higher, e.g. power supplies for a wide range of electrical equipment. Liquid level sensor. Look-Like Thermocouple A thermocouple or thermocouple thermometer is a junction between two different metals that produces a voltage related to a temperature difference. Thermocouples are a widely used type of temperature sensor for measurement and control[1] and can also be used to convert heat into electric power. They are inexpensive[2] and interchangeable, are supplied fitted with standard connectors, and can measure a wide range of temperatures. The main limitation is accuracy: system errors of less than one kelvin (K) can be difficult to achieve Applications Thermocouples are suitable for measuring over a large temperature range, up to 2300 °C. They are less suitable for applications where smaller temperature differences need to be measured with high accuracy, for example the range 0–100 °C with 0.1 °C accuracy. For such applications thermistors and resistance temperature detectors are more suitable. Applications include temperature measurement for kilns, gas turbine exhaust, diesel engines, and other industrial processes Types of Thermo-couples Type K (Chromel / Alumel) Type E (Chromel / Constantan) Type J (Iron / Constantan) Type N (Nicrosil / Nisil) Type B (Platinum / Rhodium) Type R (Platinum / Rhodium) Type S (Platinum / Rhodium)