Northwestern University Rod Ruoff Nanotechnology

advertisement

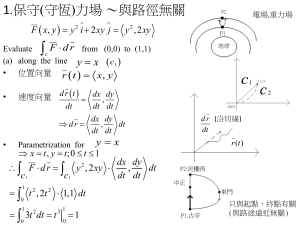

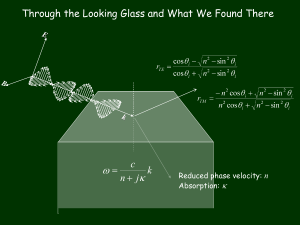

Fracture Mechanics of OneDimensional Nanostructures Northwestern University Rod Ruoff Nanotechnology Carbon Nanotube Source Arc-grown Multi-wall Carbon Nanotubes (MWCNTs) from MER Corp. AZ. were studied in this work. A simple fractionation process was used to remove some impurities and increase nanotube concentration. SEM image of powdered cathode deposit core material with 30-40% MWCNT content from MER Corp. Northwestern University SEM image of separated MWCNTs on a silicon wafer, after fractionation. Rod Ruoff Nanotechnology Testing Tool: Nanomanipulator A home-built nanomanipulator is used to perform mechanics study inside vacuum chamber of an scanning electron microscope (SEM). Piezoelectric Actuator X-Y Stage Z-stage Nanomanipulator inside vacuum chamber of FEI Nova 600 SEM (Ruoff group) Home-built nano-manipulator X-Y stage Piezo bimorph Northwestern University Z stage Cantilever Holder Specimen/ Cantilever Holder Rod Ruoff Nanotechnology Nanoscale Tensile Test Atomic force microscope (AFM) cantilevers are used as manipulation tools and force-sensing elements. Tensile Test Schematic Experimental Setup X-Y Stage soft cantilever L rigid cantilever Z Stage L+ MWCNT Northwestern University s Rod Ruoff Nanotechnology In situ Clamping - EBID Electron beam induced deposition (EBID) is the process of using a highintensity electron beam to deposit structures on a scanned surface. EBID is commonly used to make clamps in situ inside SEM. EBID clamp Hydrocarbon molecules Exposure area EBID principle Northwestern University A CNT in contact with an AFM tip, before and after EBID clamping Rod Ruoff Nanotechnology “Sword-in-sheath” Fracture Multi-wall carbon nanotubes fracture in a “sword-in sheath” manner during tensile test. Cross-sectional area: Inner shells A πDΔ Outer shell D : inter-layer separation of graphite, 0.34 nm Northwestern University Rod Ruoff Nanotechnology MWCNT Diameter Measurement Cantilever holders were designed to hold a shortened AFM chip for nanotube diameter measurement in TEM. AFM cantilevers (a) AFM chip holder model (b) An AFM chip in the AFM chip holder Northwestern University (c) Gatan TEM straining holder (model 654) (d) SEM and TEM images of a MWCNT fragment attached to an AFM tip. Rod Ruoff Nanotechnology Stress & Strain Measurements The whole tensile testing process was recorded by taking SEM images at each loading step. Northwestern University Rod Ruoff Nanotechnology MWCNT Tensile Testing Result Fracture Strength Elastic Modulus Average elastic modulus: ~ 910 GPa Northwestern University Rod Ruoff Nanotechnology Multiple Loading (Tube #6) (1) (2) (3) Test # Gauge Length (m) Breaking Force (nN) Tensile Strength (GPa) Failure Strain (%) Elastic Modulus (GPa) 1 4.08 220 21 1.4 1.8 0.3 1200 210 2 3.75 240 23 1.4 1.9 0.3 1250 210 3 3.46 420 41 2.6 3.0 0.2 1230 130 Northwestern University Rod Ruoff Nanotechnology Nanoparticle Chain Aggregates Stretching a chain Carbon nanoparticle chain aggregates Tensile Testing Contact Force Measurement • Nanoparticle diameter: 25-35 nm • Chain length: ~ 2 m • Breaking Force: 42 25 nN • Tensile Strength: 40 -100 MPa • Elastic Modulus : 200 - 600 MPa • Particle Contact Force: 8 4 nN Northwestern University Rod Ruoff Nanotechnology Nonlinearity: Large Deflection + Misalignment L EI x x (x,y) s d M Fy ( L x x) Fx ( y y ) ds where Fx=Fsin and Fy=Fcos y 0 Fx F EI 0 1 ( d ) 2 2 0 2L sin o sin y y dy 0 y Fy F EI 2F x L EI 2F 0 0 0 0 sin d sin(0 ) sin( ) cos d sin(0 ) sin( ) (Transformation; Converting to elliptic integrals) EI ( F (k ) F (1 , k ))2 2 L E (k ) E (1 , k ) 2k cos1 y (1 2 ) cos sin L F (k ) F (1 , k ) F (k ) F (1 , k ) F x 1 (1 2 E (k ) E (1 , k ) 2k cos1 ) sin cos L F (k ) F (1 , k ) F (k ) F (1 , k ) F(k),F(,k) complete and incomplete elliptic integral of first kind. k and 1 are obtained from angle 0 with following relationships: sin 0 2k 2 1 Northwestern University Rod Ruoff sin 1 2 2k Nanotechnology Experimental Data Analysis • AFM cantilevers were used as force-sensing elements in our nanoscale tensile testing experiments on templated carbon nanotubes inside SEM. • Large deflection of the cantilever beam was encountered in the tests along with non-ideal alignment of the specimens. • The linear analysis underestimated the applied load up to 15 %. Slope 0 (degree) Loading Angle (degree) Vertical Deflection y Applied Load Linear (N) Analytical (N) Error (%) Measured (m) Linear (m) Analytical (m) 11.0 36.8 25.3 29.7 14.8 42.9 42.2 42.3 17.4 5.5 23.5 24.9 5.6 68.7 70.8 70.3 9.22 42.0 20.8 23.9 13.0 30.6 32.2 32.3 11.6 2.0 19.4 19.6 1.0 41.4 40.5 40.4 15.0 24.3 27.6 31.4 12.1 52.9 52.4 52.3 Northwestern University Rod Ruoff Nanotechnology Error in Linear Estimation Normalization Linear analysis FL K yL / cos 2 EI0 2 L cos FL L2 2 0 EI cos yL 2 3 2 0 L 3 yL 0 L Analytical analysis F EI 0 1 ( d ) 2 2 0 2L sin(o ) sin( ) EI ( F (k ) F (1 , k ))2 2 L y EI 0 sin y dy d 0 2 F 0 sin(0 ) sin( ) E (k ) E (1 , k ) 2k cos1 (1 2 ) cos sin L F (k ) F (1 , k ) F (k ) F (1 , k ) FA L2 ( F (k ) F (1 , k ))2 EI yA E (k ) E (1 , k ) 2k cos1 (1 2 ) cos sin L F (k ) F (1 , k ) F (k ) F (1 , k ) Northwestern University Rod Ruoff Nanotechnology