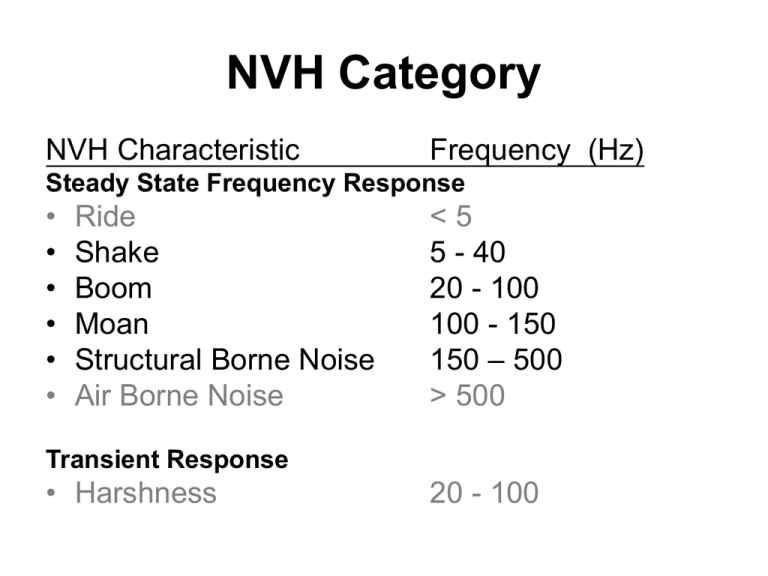

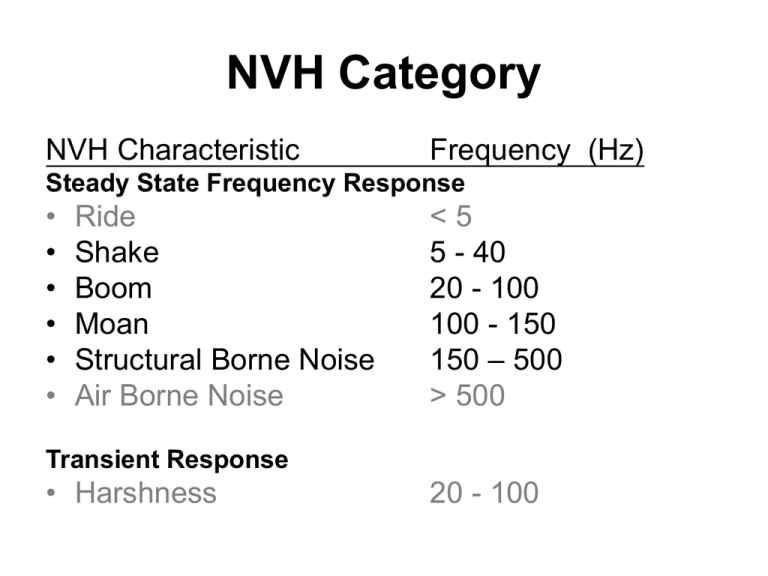

NVH Category

NVH Characteristic

Frequency (Hz)

Steady State Frequency Response

•

•

•

•

•

•

Ride

Shake

Boom

Moan

Structural Borne Noise

Air Borne Noise

<5

5 - 40

20 - 100

100 - 150

150 – 500

> 500

Transient Response

• Harshness

20 - 100

Single Degree of Freedom

Amplitude (20% Damped)

Control by

Damping

Control by

Dynamic

Stiffness

Control by

Mass

Isolation Region

Frequency (Hz)

fn

2 * fn

Dynamic Stiffness

Dynamic Stiffness:

(K - m ω2) – j C ω

K* = ---------------------------------(K - m ω2)2 + (C ω)2

Mass M

Stiffness K

Damping C

ω = 2* π*f

f is the frequency

Pure Tone

• Sound at a single frequency

• Sound Pressure

– Objective measurement

• dB

– Logarithmic of sound pressure

• dBA

– A-Weighted to adjust for ear sensitivity

Human Sensitivity

• More constant across frequency range

with velocity

• Hearing range 20 – 2000 Hz

• Depends on overall level

• Sound at one frequency may mask by

other frequencies

• Depends on age, sex and other factors

Tactile Response

Subjective-Objective

Acceleration

SR = 5

SR = 6

Frequency

Tactile Response

Subjective-Objective (2)

Velocity

SR = 5

SR = 6

Frequency

Sound Pressure Level

and A Weighting

NVH Classification

• Operating Condition

– Idle, Low Speed, Cruising, POT, WOT

• Subjective Evaluation

– Shake, Boom, Noise, Harshness

• Objective Measurement

– Sound Pressure, Acceleration

• Frequency Range

• Source

– Powertrain, Road, Exhaust

NVH Subjective Rating

No Sale

Most

Targets

NVH Objectives

• Assess vehicle responses relative to

design targets:

–Tactile responses

• Seat track

• Steering column

• Toe pan

–Acoustic responses

• Driver’s ear

• Front Passenger’s ear

• Rear passenger’s ear

Shake

•

•

•

•

•

5 – 40 Hz

Idle Shake

Isolated Road Shake

Rough Road Shake

Smooth Road Shake

– Wheel/Tire Imbalance

– Tire Force Variation

Design For Shake

• Body vertical, lateral bending and torsion

modes

• Front end bending and torsion modes

• Front floor modes

• Steering column modes

• Seat modes

• Avoid stickiness of the shock and CV

joints that causes high force input and

resonance in smooth road shake

Design For Shake (2)

• Mode separation and mode shape

management of engine bounce, roll, pitch

and yaw rigid body modes

Boom

•

•

•

•

20 - 100 Hz

Idle Boom

Isolated Road Boom

Rough Road Boom

Body Design for Boom

•

•

•

•

•

•

•

•

1st and 2nd fore-aft acoustic modes

Body 1st and 2nd order vertical bending

Front floor vertical bending

Dash panel fore-aft bending

Quarter panel bending

Fuel tank bounce

Spare tire tub bounce

Decklid, liftgate or lower back panel pumping

Structural Borne Noise

•

•

•

•

100 - 500 Hz

Powertrain Noise

Rough Road Noise

Gear Whine

Design For Noise

• Most of the vibration energy imparted to the vehicle

is below 150 Hz.

• Below 150 Hz:

– Body structure is important for controlling noise and

vibration

– Lack of structure usually results in costly design and

tooling changes

• Above 150 Hz:

– Can be resolved with relatively simple structure

modifications, such as bead patterns, or damping

treatments.

Design For Noise (2)

• Powertrain Bending Isolation

• Powertrain Bracket Isolation

Modal Chart

CHASSIS/POWERTRAIN MODES

Suspension Hop and Tramp Modes

Ride Modes

Suspension Longitudinal Modes

Powertrain Modes

0

5

10

15

Exhaust Modes

20

25

30

35

40

45

50

Hz

BODY/ACOUSTIC MODES

Body First Torsion (25Hz)

Steering Column First Vertical Bending (29Hz)

Body First Bending (22Hz)

0

5

10

15

First F/A Acoustic Modes (48Hz)

20

25

30

35

40

45

50

Hz

EXCITATION SOURCES

Inherent Excitations (General Road Spectrum, Reciprocating Unbalance, Gas Torque, etc.)

Process Variation Excitations (Engine, Driveline, Accessory, Wheel/Tire Unbalances)

First Order Wheel/Tire Unbalance (5-75MPH)

0

5

10

15

20

25

V8 Idle (500-550RPM)

Hot Cold

30

35

40

45

50

Hz

Body-in-White Targets

• Static Stiffness

– Bending

– Torsion

• Normal Modes

– Vertical bending

– Torsion

– Lateral bending

Trimmed Body Targets

• Normal Modes

– Vertical bending

– Torsion

– Lateral bending

– Front end bending

– Front end torsion

Instrument Panel/Column

Targets

• Normal Modes

– Vertical bending

– Lateral bending

Seat Targets

• Normal Modes

– On Bedplate

• Fore aft

• Lateral

– In Vehicle

• Fore aft

• Lateral

• Different row may have different target

Idle Load

Idle Torque

Pbore

mrecip

Ttotal ( Fgas Frecip ) * h * tan

arecip

h

L

r

Pcrank

Frecip mrecip * arecip

Fgas (Pbore Pcrank ) * Abore

Piston Displacement

Pbore

mrecip

h L cos r cos

cos 1 sin 2

arecip

h

L

r sin

sin

L

L cos L 1 sin 2

r

Pcrank

h L 1 sin 2 r cos

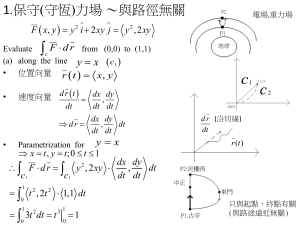

Trigonometric Derivatives

Pbore

mrecip

recip

h

L

r

Pcrank

d sin

d

cos

dt

dt

d cos

d

sin

dt

dt

n

du

n 1 du

nu

dt

dt

d (u v) du dv

dt

dt dt

duvw

dw

dv

du

uv

uw vw

dt

dt

dt

dt

Piston Velocity

Pbore

mrecip

arecip

h

L

r

Pcrank

dh d

v

( L cos r cos )

dt dt

d

r 2 cos sin

r sin 2 2 2

dt

L r sin

r cos sin

r sin

2

2

2

L r sin

Piston Acceleration

Pbore

mrecip

dv

d

r cos sin

a

(r ) (sin

dt

dt

L2 r 2 sin 2

arecip

h

L

r

Pcrank

2

r

cos 2

2 r cos

L2 r 2 sin 2

r 4 cos2 sin 2

3

( L2 r 2 sin 2 ) 2

)

Smooth Road Shake

Wheel/Tire Imbalance

Definition

• Simulation

– Shake caused by the unbalanced inertia forces

from the high speed rotation of the unbalanced

wheel in vehicle cruising

• Load

– 1.0 oz-inch (Sensitivity) unbalanced force at the

spindles

– Both vertical and fore-aft loads with vertical load

trailing fore-aft load by 90 degrees

• Applications

– Front wheel in-phase, Front wheel out-of-phase,

Rear wheel in-phase and Rear wheel out-of-phase

Wheel/Tire Imbalance

Calculation

• F = mr2

–

–

–

–

F is imbalance Force (N)

m is imbalance mass (Mg)

r is imbalance radius (mm)

is rotation speed (rad/sec)

• F = 1.0 oz-in = 1.0 * 28.3 * 10-6 (Mg/oz) * 25.4

(mm/inch) * 4 * 2 * f2 = 0.0284 * f2 (N)

– f is frequency (cycles/sec)

Wheel/Tire Imbalance

Speed Map

• The wheel/tire speed map (frequency v.s.

vehicle speed) is dependent on the wheel/tire

size, the wheel/tire stiffness and the payload

• V = 2 * π * Tire Effective Radius * Frequency

• However, the Frequency/Vehicle Speed(MPH) is

typically around 0.2

• Based on the above assumption, the frequency

range of interest from 25 MPH to 125 MPH is

– 5 Hz to 25 Hz

Tire Force Variation Definition

• Simulation

– Shake caused by the variation of the radial stiffness of

the tires

• Load

– 1.0 lbf (Sensitivity) variation force at the spindles

– Vertical load only

• Applications

– Front wheel in-phase, Front wheel out-of-phase, Rear

wheel in-phase and Rear wheel out-of-phase

Tire Force Variation

Speed Map

• The wheel/tire speed map (frequency v.s.

vehicle speed) is dependent on the wheel/tire

size, the wheel/tire stiffness and the payload

• V = 2 * π * Tire Effective Radius * Frequency

• However, the Frequency/Vehicle Speed(MPH) is

typically around 0.2

• Based on the above assumption, the frequency

ranges of interest from 25 MPH to 125 MPH are

– First Order : 5 Hz to 25 Hz

– Second Order : 10 Hz to 50 Hz

Rough Road Noise

Spatial PSD Road Profile

• Spatial Frequency ( Cycles / mm)

– Wave number

– 1 / wavelength

• PSD Amplitude (mm^2 / (cycles / mm))

• Power Regression Analysis (Y = 1.7872 * X-0.6729)

Spacial PSD Road Profile

PSD (mm^2/(cycles/mm))

1000

100

-0.6729

10

1

0.0001

y = 1.7872x

R2 = 0.6538

0.0010

0.0100

Wave Number (cycles/mm)

0.1000