Title of Presentation

advertisement

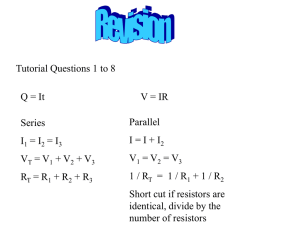

OPTI 521 – Fall 2010 Tutorial Jeffrey T Daiker Effect of temperature on focus Athermalization of focus Optically passive Mechanically passive Electromechanically active Conclusion References OPTI 521 – Fall 2010 Daiker Tutorial 2 Defocus with temperature change due to the nature of IR lens materials g the thermo-optical coefficient of the lens is positive for most IR lens materials and indicates a negative change in focal length with temperature OPTI 521 – Fall 2010 Daiker Tutorial 3 Tolerable temperature change for a Ge lens 100 delta T (deg C) F/4 F/2 F/1 10 1 0.1 0 0.1 0.2 0.3 lens diameter (m) OPTI 521 – Fall 2010 Daiker Tutorial 4 Combine suitably chosen lens materials which together compensate for thermal defocus Athermal achromat Total power Achromatism Athermalization OPTI 521 – Fall 2010 Daiker Tutorial 5 Example: Si, Ge, ZnS Optimum three-material solution Config 1 Config 2 0.0000 (deg) +20⁰C +60⁰C 40.00 -20⁰C Config 3 Surface: IMA Layout Total Axial Length: Configuration Matrix Spot Diagram Units are µm. 1.01268 mm athermal achromat 216 v1.ZMX Configuration 3 of 3 OPTI 521 – Fall 2010 Scale bar : 40 Daiker Tutorial Airy Radius: 19.02 µm Reference : Chief Ray athermal achromat 216 v1.ZMX Configuration: All 3 6 Optically passive athermalization very complex Zoom lens is extreme case where completely passive athermalization generally not possible Utilize optical design software OPTI 521 – Fall 2010 Daiker Tutorial 7 Before doing any thermal modeling Set TCE of air spaces OPTI 521 – Fall 2010 Daiker Tutorial 8 Built-in tool in the Multi-Configuration Editor Add different temperature configurations OPTI 521 – Fall 2010 Daiker Tutorial 9 MCE should look something like this OPTI 521 – Fall 2010 Daiker Tutorial 10 Carefully construct merit function Minimize RMS wavefront between two temperatures, for example Optimization using glass substitution Create a glass catalog from a short list (Si, Ge, ZnS, ZnSe, MgO, KRS5, AMTIR1, CaF2 for 3-5 microns) No guarantee solution is global optimum Use design practices, experience, and resources OPTI 521 – Fall 2010 Daiker Tutorial 11 Involves some method of moving a lens element or elements by an amount that compensates for thermal defocus By using two different materials with very different TCE arranged as either differential expansion cylinders or rods, it is possible to move the compensating element directly Rods or cylinders must be of sufficient length OPTI 521 – Fall 2010 Daiker Tutorial 12 Combine spacers of length L1 and L2 with TCE a1 and a2 respectively, then to athermalize over distance L Using materials with a > 0 requires L < 0 OPTI 521 – Fall 2010 Daiker Tutorial 13 Relies on compensator elements driven in a temperature controlled manner using information from separate temperature sensors Brute force solution Most suitable for complex systems such as zoom lenses where an electomechanical focus mechanism already exists OPTI 521 – Fall 2010 Daiker Tutorial 14 Example: all-reflective system consisting of aluminum mirrors in an aluminum housing OPTI 521 – Fall 2010 Daiker Tutorial 15 Optically passive Single FOV Dual FOV Zoom Performance X Mechanically passive X Very good Good Reliability Very good Fair to good Weight Very light Can be heavy and bulky Power requirements Environmental Very good stability Ease of maintenance Excellent Cost Cheap OPTI 521 – Fall 2010 Good Good Fairly cheap Daiker Tutorial Electromechanically active X X X Depends on technique Depends on components Heavy X Concerns under vibration Fair to good Expensive 16 1. 2. 3. 4. 5. 6. 7. Povey, V. “Athermalisation Techniques in Infra Red Systems,” Proc. of SPIE Vol. 0655, Optical System Design, Analysis, and Production for Advanced Technology Systems, ed. Fischer, Rogers (Apr 1986) Rogers, P. “Athermalization of IR Optical Systems,” Critical Review Vol. CR38, Infrared Optical Design and Fabrication, ed. R. Hartmann, W.J. Smith (Apr 1991) Jamieson, T. “Athermalization of optical instruments from the optomechanical viewpoint,” Critical Review Vol. CR43, Optomechanical Design, ed. P.R. Yoder, Jr. (July 1992) Rayces, J. “Thermal compensation of infrared achromatic objectives with three optical materials,” SPIE Vol. 1354, International Lens Design Conference (1990) Riedl, M. “Optical Design Fundamentals for Infrared Systems,” tutorial texts in optical engineering; v.TT20, SPIE Rogers, P. “Thermal Compensation Techniques,” Handbook of Optics, Volume I, Part 9, Chapter 39. McGraw-Hill, 1995. Zemax Knowledge Base. 2010. http://www.zemax.com/kb/articles/106/1/How-toModel-Thermal-Effects-using-ZEMAX/ OPTI 521 – Fall 2010 Daiker Tutorial 17