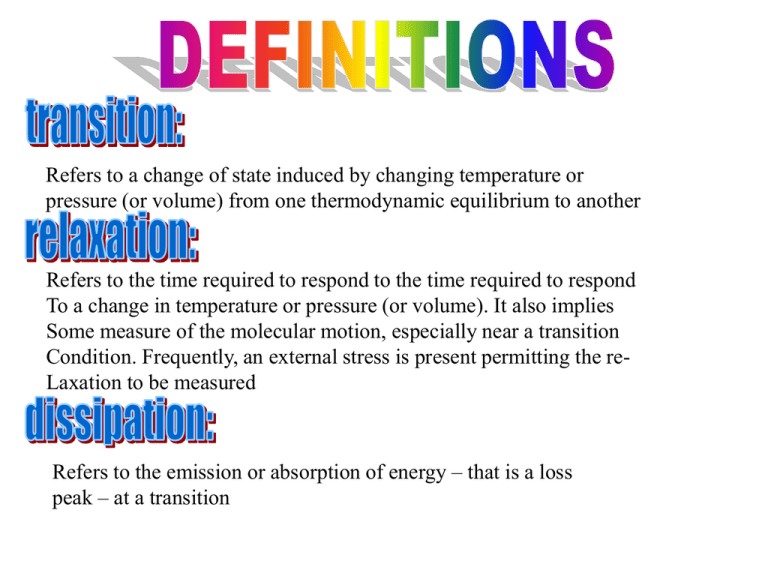

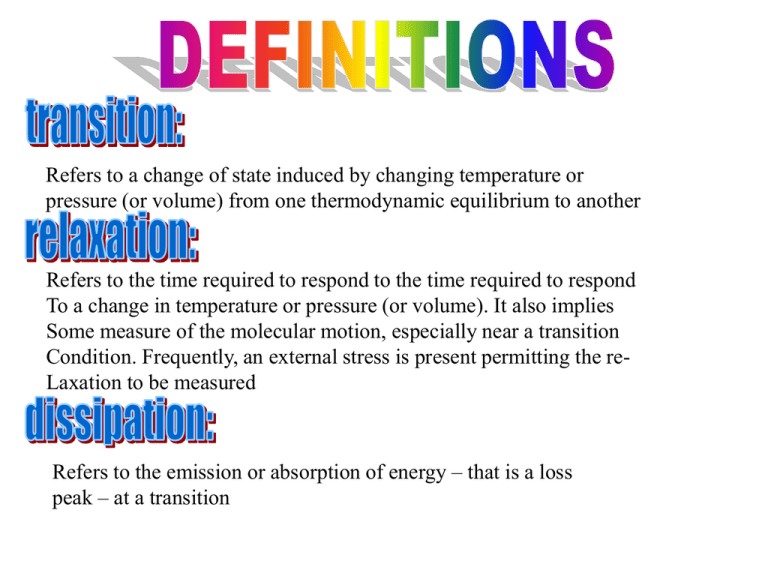

Refers to a change of state induced by changing temperature or

pressure (or volume) from one thermodynamic equilibrium to another

Refers to the time required to respond to the time required to respond

To a change in temperature or pressure (or volume). It also implies

Some measure of the molecular motion, especially near a transition

Condition. Frequently, an external stress is present permitting the reLaxation to be measured

Refers to the emission or absorption of energy – that is a loss

peak – at a transition

heat flux

or

cp

poly(dimethyl siloxane) (PDMS)

•glass transition

•enthalpy relaxation

•cold crystallization

•melting

H

H

dH

dT

T p , ni

p

dH p , n

i

n

H

dp

dni

n

i

1

T , ni

i p , T , n j i

H

dT

T p , ni

cp

ni ni 0 i dni i d

dH T , p i H

n

i 1

ni p ,T , n ji

i

H

T , p

d

n

i 1

i

i

differential enthalpyof reaction

c~p specificheatcapacity

c p molarheatcapacity

ni amountof subst ancecomponenti

i st oichiometriccoefficient of thecomponenti in a reaction

extendof reaction

i chemicalpot ent ialof thecomponenti

H

c~p

H

T

p

c~ dT dH

c~p dT

p

T

H

Q

c~p

Q

t p , n t p , n t p , n

i

i

i

T

T(t)

slope:

T

m *

t p

and from above :

1

Q

T

~

m * ~ Q c p

m*

t p c p

Cp can be calculated from the heat flux Q

Q is determined by the exactness of the signal

t

M*is determined by the exactness of the program rates

Consequently, a correction is needed that is independent of

the parameters of the instrument:

c~p Q sample Q sample msample

c~ Q sapphire Q sapphire msample

p

M. J. O`Neill, Anal. Chem. 38 (1966) 1331

Q

H

c~p T Ttrans H trans

t p

T p

Tg, Tm, Tcr, TS-N, TSA-SC,…TN-I…

Classification of the thermodynamic transitions

according to Paul Ehrenfest*):

Discontinuity the derivative (1st, 2nd,…) of the Gibbs function G

G H TS dG dH TdS SdT

G

G

dG

dp

dT

T p , n

p T , n

i

S

i

n

i 1

G

dni

ni p , n

V

dG T , S dH

*)Ehrenfest

P Proc Kon Akad Wetensch Amsterdam (1933) 36, 153

j i

i

First Order Transitions

In a real experiment heat transfer requires time

and a temperature gradient

and this is what we actually see:

a (endothermal) melting peak

Hoffman & Weeks Plot*

Tm0 Tm T 0mTc

thermodynamic equilibrium

melting temperature

stability parameter

isothermal crystallization temperature

experimental melting temperature

Tm

Tm0

Tm Tm0

Tm Tc

1

slope

Tm 1 Tm0 Tc

intercept

0 Tm Tm0 most stable

1 Tm Tc unstable

0.5 is the most common case

Tc

J. D. Hoffman, J. J. Weeks, J. Res. Bureau Standards 66A (1962) 13 *(solution crystl.)

Volume

Enthalpy

Storage modulus

At the glass transition

Expansivity

Heat capacity

Loss modulus

Vspec

Hspec

high cooling rate CR1

low cooling rate CR2

Tg2

Tg1

T

(dV/dT)~ a

(dH/dT)p= cp

Ti2 Tg2

Te2

Tg1

Tcr

Calculation of Tg according to

M. J. Richardson, N. G. Savill, Brit. Polym. J. 11 (1979) 123

Tg determined independent of the heating rate

integration

time