Training course - Jan 2014

advertisement

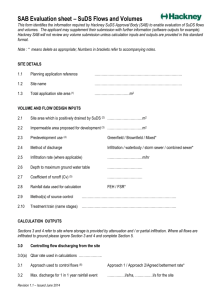

Weetwood Surface Water Training 10 January 2014 Geoff Waite Agenda TOPIC TIME STAFF Historical Background to Sewer Hydraulics 09.00 - 09.30 KB, AE, HE Modified Rational Method 09.30 - 10.30 KB, AE, HE Micro Drainage – Basic Tank/Pond 10.30 - 11.00 KB, HE Micro Drainage – Flow Controls 11.00 - 11.30 KB, HE Micro Drainage – Complex Controls 11.30 - 12.00 KB, CC, AE, HE Lunch Micro Drainage – Other SUDs Components 12.45 - 13.45 KB, CC, AE, HE Micro Drainage – Cascade 13.45 - 14.15 KB, CC, AE, HE Interception Losses and Long Term Storage 14.15 - 15.00 KB, CC, AE, HE Break Drainage Strategy and Deliverability 15.15 – 17.00 Close KB, CC, AE, HE, RE Sewer Hydraulic Calculations Method Year Lloyd Davies – Rational Method 1906 TRRL (Watkins) Method 1962 Wallingford Procedure 1981 InfoWorks 1996 Definitions • Types of Sewerage System • Separate Sewerage Systems • Combined Sewerage Systems • Partially Separate Sewerage Systems • Ancillaries – overflows, pumping stations, attenuation tanks, dual manhole • Standard Technical Committee Report 25 (STC25) Lloyd Davies – Rational Method • Put simply: flow = impermeable area multiplied by rainfall intensity • Method originally developed to size pipes rather than to calculate flow rates • Main difficulty is how to calculate the correct rainfall intensity to use in the analysis • Provides only a peak flow (not a hydrograph) Rational Method - Assumptions • Rainfall - uniform intensity over whole catchment being analysed • Pipes run full (i.e. storage, surcharge and flooding is ignored) • The whole area upstream contributes to runoff at the location being analysed Rational Method Q = 2.78 * imp area * rainfall intensity • 2.78 is a factor to calculate flows in litres/sec if the impermeable area is in hectares and the rainfall intensity is in mm/hr • Flow is at a maximum when the whole area upstream just starts to contribute runoff at the point of consideration • The time at which this occurs (which is different for every pipe in the network) is known as the Time of Concentration Sewer Hydraulics Background Sewer Hydraulics – Background (1) • Rational Method known to over estimate flows • Key weaknesses – uniform rainfall intensity, using the whole catchment upstream of the point of analysis and ignoring storage available in the pipe system • Other weaknesses include catchment shapes, unable to deal with surcharge and effect of any ancillaries Be wary of carrier pipes with no impermeable areas Sewer Hydraulics – Background (2) • TRRL – introduced for design of pipes on motorways • Computer Method running on mainframe computers • Incorporated variable rainfall intensities, area/time diagrams and allowed for pipe storage • Produces Hydrographs • Shortcomings – could not analyse surcharge/flooding and no ancillary modelling available Sewer Hydraulics – Background (3) 1981 – Wallingford Procedure (Four Main Volumes) • Software – WASSP running on mainframes • Utilised rainfall data from the 1975 Flood Studies Report and rainfall/runoff research for urban areas • Separate inputs (RED, SSD) and models for rainfall, urban rainfall/runoff process, pipe analysis and ancillaries • Pipe analysis included surcharge and flooding (although to a limited extent) Sewer Hydraulics – Background (4) • Modified Rational Method is Volume 4 – utilised the findings of the Wallingford Procedure • Rainfall data and urban rainfall/runoff models were incorporated into the procedure Sewer Hydraulics – Background (5) • Circa 1990 - Wallingford software circa converted to run on a pc and called WALLRUS • Weaknesses - pipe analysis was limited to dendritic systems and could not deal with reverse flows • Intermediate software introduced circa 1994 to handle reverse flows and backwater effects – SPIDA • Infoworks introduced circa 1996 – fully pc based Sewer Hydraulics – Background (6) • Infoworks is GIS Based information using STC25 Referencing • Separate databases for nodes, links and area information • New pipe analysis software based upon St Venant open channel flow equations (deal with reverse flows) • Internationally applicable with different runoff models for different countries/catchments • Dry Weather Flow (foul sewage) generator and Water Quality analysis Modified Rational Method Q = 2.78 * Cv * CR * i * A • Cv is the volumetric runoff coefficient (proportion of rainfall which enters the pipe network) • CR is a routing coefficient = 1.3 • i is rainfall intensity • A is imp area MRM – Input Parameters 1. Site Areas (Impermeable and Permeable) 2. Rainfall (M5-60, ratio and SAAR) 3. Soil Type/Soil Index 4. Time of Entry 5. Time of Flow MRM – Derived Parameters 1. Time of Concentration = Time of Entry + Time of Flow 2. Urban Catchment Wetness Index (UCWI) 3. Percentage Impermeable Area (PIMP) 4. Percentage Runoff (Pr) 5. Cv MRM – Pr Equation Pr = 0.829*PIMP + 25*SOIL + 0.078*UCWI - 20.7 • Cv = Pr / PIMP • Limitations of the Pr equation MRM – Rainfall Calculation • Rainfall intensity based upon the time of concentration • Obtain the M5- 60 and rainfall ratio values • Calculate M5-D (where D is the time of concentration) – using the Z1 coefficient • Calculate MT-D rainfall depths (where T is return period) • Determine appropriate rainfall intensities MRM - Spreadsheet Example of using the Spreadsheet Micro Drainage – Basic Tank/Pond • Source Control Basic Principles • Quick Storage Estimate • Tank/Pond Source Control – Basic Principles (1) • Firstly, always sketch out the layout of the component including levels • For any SUDs component there is: – Inflow – principally rainfall – One, two or three outflows 1. Infiltration 2. Flow Control (primarily controls the filling of the component) 3. Overflow (when the storage is full) There must be at least one outflow but all three can be used Typical SUDs Component Rainfall Overflow SUDs Component Control Component provides Storage Infiltration (Sides/Base) Source Control – Basic Principles (2) For each SUDs component we need to define: 1. Global Variables – overview of inflow, component, controls, climate change 2. Rainfall - inflow 3. Area Time Diagram – impermeable areas 4. Details of the SUDs component itself 5. Details of Flow Controls/Overflows/Infiltration Quick Storage Estimate • Useful tool for quick calculation • Provides estimated storage requirements with or without infiltration • Provides results for a range of infiltration components • Useful way to input data required for analysis Basic Tank/Pond Freeboard Pipe Inflow above max storage level Design Fill Level Flow Control Outflow at Base Basic Tank/Pond • Adam to Continue Micro Drainage – Flow Controls • Orifice • HydroBrake • Weir • Complex Control – more than one control • ALL flow controls use a head/discharge relationship • Can be lower than the base of the SUDs component Flow Control - Orifice 1.6 1.4 Head in m 1.2 1 0.8 0.6 0.4 0.2 0 0.0 10.0 20.0 30.0 40.0 Flow in litres/sec 50.0 60.0 70.0 Flow Control - Hydrobrake Self activating vortex with air core Type MD1 Hydrobrake 210mm diameter Type MD12 Hydrobrake, 272mm diameter • • • 1.8 1.6 1.4 Head in m 1.2 1 Orifice 0.8 Hydrobrake MD12 0.6 Hydrobrake MD1 0.4 0.2 0 0.0 10.0 20.0 30.0 40.0 Flow in litres/sec 50.0 60.0 70.0 Flow Control - Weir Flow Control – Complex Control • Two controls at different levels to satisfy 2 year, 30 year and 100y+cc flow rates • Normally hydrobrake/orifice combination Flow Control – Complex Control • Lower control – hydrobrake for 2 year flow • Higher control – normally orifice with soffit set at 2 year water level • Hydrobrake and orifice pass forward 100y+cc flow when component is full • Complex control builder – trial and error • Analyse with SUDs component and check results for 2 year, 30 year and 100 year+cc flow rates • Adjust as necessary (may need to adjust control and component) Micro Drainage – SUDs Components 1. Soakaway - Lined and House 2. Permeable Paving 3. Cellular Storage 4. Swale 5. Pipe Storage SUDs Components – Lined Soakaway • • • Comprises circular concrete manhole rings with holes Constructed within a square excavation filled with porous stone Infiltration at base and sides SUDs Components – House Soakaway • • Comprise a square excavation filled with porous stone Typically one per house SUDs Components – Permeable Paving Clay pavers CBPP (Concrete Block Permeable Paving) Gravel Grass paving Permeable Resin-bound aggregate Self-binding golden gravel Permeable Macadam Permeable/ No-fines concrete SUDs Components – Permeable Paving • • • • Typically 600mm deep 400mm porous stone, 200mm blocks With or without infiltration Consider longitudinal gradient Block Paving Design Fill Level Porous Stone SUDs Components – Permeable Paving • • • • Typically 600mm deep 400mm porous stone, 200mm blocks / laying course With or without infiltration Consider longitudinal gradient Grit not sand Course graded aggregate SUDs Components – Cellular Storage • • • • Cellular Units typically 350mm or 660mm deep Cover required – 500mm landscaped areas and 600mm to 1m depending on traffic loads With or without infiltration Consider longitudinal levels Cover to Units Units Design Fill Level Sound undisturbed earth or prepared subgrade Coarse Sand/Gravel SUDs Components - Swale • Overall Depth typically 500mm • Freeboard 150mm • Consider Longitudinal Gradient Freeboard Side Slopes 1 in 4 Base Width (variable) SUDs Components – Pipe Storage • Generally Source Control only applicable for simple pipe systems • Manholes provide large storage volumes of storage (not accounted for in Source Control) • Consider Longitudinal Gradient Micro Drainage - Cascade • Joining together one or more SUDs Components • Components can be linked in a chain • Multiple components can be connected to a single component • The flow control and the overflow can link to a downstream Component • Some components can have infiltration • Non upstream components need not receive runoff from rainfall • Relative levels between components are not considered (beware! because Source Control only analyses levels for individual components) • Must be one outfall? Cascade Example Cascade Process 1. Design Individual SUDs components 2. Downstream Components – take account of upstream inputs and/or rainfall 3. Link together in cascade facility 4. Analyse 5. Review results and adjust downstream components and re-analyse Interception Storage • 50% of rainfall events < 5mm • No measurable runoff from greenfield areas • Runoff from a development takes place for virtually every rainfall event - frequent discharges with polluted runoff • Interception storage - prevent any runoff from rainfall depths up to 5mm. • Certain SuDS features such as swales and pervious pavements provide runoff characteristics that reflect this behaviour Long Term Storage Vol = RD.A.10[ Where: Vol RD PIMP A SPR PIMP 100 (α 0.8) + 1- PIMP 100 (β.SPR) – SPR] = the extra runoff volume (m3) of development runoff over greenfield runoff = rainfall depth for 100 year, 6 hour event (mm) = Impermeable area as a percentage of total area = area of site (ha) = standard percentage runoff index for the soil type = proportion of impermeable surface draining to network / receiving waterbody = proportion of permeable surface draining to network / receiving waterbody 100 year 6 hour Rainfall Depth 100 year 6 hour Rainfall Depth Drainage Strategy Detail • Pre-planning • • • Informing the masterplan - Opportunities & Constraints Deliverability SuDS & land take • Planning • • • • NPPF Demonstrating a feasible solution EA, LLFA / LPA and IDB requirements Deliverability & flexibility for the detailed design Detailed Design/Planning Conditions • By this stage the development proposals (layout/site levels) are finalised • The foul and SW pipe systems can be designed • Use Micro Drainage Simulation to analyse the SW pipe network including controls • Design Outputs – plans, long section, manhole drawings (with emphasis on the flow control manhole) • Brief report Storage – 1 in 30 year and 1 in 100 year plus climate change • Is the pipe system to be adopted by the water company under a Section 24 agreement? • If so, the pipe system must: – Run free (no surcharge) in the 1 in 2 year event – No flooding in the 1 in 30 year event • Still cater for 100 year+cc flows on site • Take account of flow control and/or restrictions Pipe Storage/Conveyance • Do pipes store the 30 year event? • Flow control and/or restriction required to do this – some flooding may result • Pipes can still contain the 30 year event even if rates are restricted to greenfield • Need to consider the interaction between the pipe network and the SUDs components (s) which requires a Simulation model Levels/Watercourse Interaction • Claire Pipe Free Conveyance Systems • Claire