Basic Skills for Mfg.: Quality Systems: Product Disposition - Bio-Link

advertisement

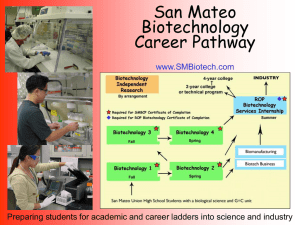

Biomanufacturing Jim DeKloe Biotechnology 101 Business and Regulatory Practices 1 Biotechnology is the intersection of Science Business Government Biotechnology 101 Business and Regulatory Practices 2 Biotechnology 101 Business and Regulatory Practices 3 Drugs versus “biotech” Traditional Pharmaceutical Biotechnology companies “Big Pharma” “Biotech” Drugs Proteins Small molecules Large Molecules Produced by Chemistry Produced by Living Organisms Example: Aspirin Example: EPO Biotechnology 101 Business and Regulatory Practices 4 History Drugs Biologics Small molecules Complicated Mixture of Large Molecules Produced by Chemistry Difficult to Test Purity Simple Pure Molecules Emphasis on Consistent Process Easy to Test Quality Examples: Example: Aspirin Vaccines, Plasma and Serum Biotechnology 101 Business and Regulatory Practices 5 Biotech clusters thrive when all elements of the industry are represented Technician Training Until recently, the emphasis on R & D meant that formal training targeting technicians was rare Community Colleges have moved into this niche Technician training will be even more important as more companies move from R & D into biomanufacturing Biotechnology 101 Business and Regulatory Practices A Model Academic - Industry Collaboration Building biomanufacturing curriculum Tailoring curriculum to develop specific required skills Incorporating regulatory requirements into curriculum Biotechnology 101 Business and Regulatory Practices Sabbatical Experience Genentech supplied Expertise Donated Equipment Presence on Advisory Committee Guest Speakers Biotechnology 101 Business and Regulatory Practices Traditional versus Industrial Traditional Industrial Education Training Lab Atmosphere Pilot Plant Atmosphere Set Times Shifts Lab Protocols SOP Lab Notebook Batch Records Individual Team Biotechnology 101 Business and Regulatory Practices Question Authority! Change Academic Paradigm Borrow vocational tech and business ideas Teach skills as well as educate Emulate the industrial experience Share the ideas that work Biotechnology 101 Business and Regulatory Practices Back to Basics - Cells Biotechnology 101 Business and Regulatory Practices 11 Eukaryotic Cells can be Engineered Also Biotechnology 101 Business and Regulatory Practices 12 Protein! The Protein is the Product! Biotechnology 101 Business and Regulatory Practices 13 Protein Structure Proteins can be modified after they are synthesized The addition of sugars – glycosylation – may be important – it affects solubility and pharmacokinetics (blood half live) Glycosylation patterns may vary Repeat because it is so important: If a protein loses this shape, it loses its function Biotechnology 101 Business and Regulatory Practices 14 Protein! The protein must not be unfolded (denatured) or it loses its function. Proteins can be denatured by: •pH extremes •temperature extremes •organic chemicals •agitation Biotechnology 101 Business and Regulatory Practices 15 Protein! DNA is the Flash Protein is the Cash Biotechnology 101 Business and Regulatory Practices 16 Protein! DNA is the Show Protein is the Dough Biotechnology 101 Business and Regulatory Practices 17 Protein! DNA is the Bling Protein is the Thing Biotechnology 101 Business and Regulatory Practices 18 Bacterial Cells – Prokaryotic Cells Biotechnology 101 Business and Regulatory Practices 19 Cells are grown in a large scale Biotechnology 101 Business and Regulatory Practices 20 Upstream Cells Divide and are transferred to larger and larger volumes Cells are induced to produce protein Many in-process samples are taken; some are sent to QC for a variety of tests. For mammalian cells, they will check for contamination by viruses and mycoplasma Biotechnology 101 Business and Regulatory Practices 21 Recovery - Downstream Cells are separated from the medium surrounding them by filtration or centrifugation. Typically: In E. coli culture (slang is fermentation), the cells are retained and the medium is discarded In cell culture (CHO cells), the cells have been engineered to secrete the protein, so the cells are discarded and the protein-containing medium is retained Biotechnology 101 Business and Regulatory Practices 22 Protein Purification The protein of interest must be separated from the other proteins in the cells or medium until it is 99.99% pure. This is accomplished by ultrafiltration and chromatography Biotechnology 101 Business and Regulatory Practices 23 Ultrafiltration In ultrafiltration the protein containing solution is passed through a filter with pores of a defined size. This can separate proteins of different sizes from one another, or can separate protein from medium components. Biotechnology 101 Business and Regulatory Practices 24 Chromatography Chromatography methods use resins of different types to exploit the characteristics of the protein to interest to separate it from other contaminating protein Biotechnology 101 Business and Regulatory Practices 25 Types of Chromatography Type of Chromatography Protein Property •Gel Filtration (Size Exclusion) - Size •Ion Exchange (Cation or Anion) – Charge •Hydrophobic Interaction Chrom. – Hydrophobicity •Affinity Chromatography - Function or Special Characteristic Biotechnology 101 Business and Regulatory Practices 26 Formulation Once the protein has been purified, the bulk purified protein will be placed in the formulation buffer and sterile filtered. During formulation, adjuncts are added to: •Stablize pH •Adjust osmolarity •Prevent aggregation •Cryoprotect (for lyophilized products) Biotechnology 101 Business and Regulatory Practices 27 Fill Fill is completed in a special facility that has highly filtered air, gowned personnel with special training, This process is highly automated. A measured amount of the formulated protein is aliquoted into sterile ampules Biotechnology 101 Business and Regulatory Practices 28 Finish The protein may be lyophilized (freeze dried). This makes it more stable, but physicians may find this form of the drug less convenient to use. Closures are added Labels are applied. Biotechnology 101 Business and Regulatory Practices 29 Quality Assurance The law requires a QA/QC department that is separate from manufacturing They will test: Raw Materials In-Process Samples Utilities Environmental Monitoring The final protein product Biotechnology 101 Business and Regulatory Practices 30 Regulation In the United States, the Food and Drug Administration regulates pharmaceutical production •Part of the executive branch •Regulates $ 1 trillion of commerce a year •Center for Drug Evaluation and Research •Center for Biologics Evaluation and Research Biotechnology 101 Business and Regulatory Practices 31 What Are GMPs? Subpart Description A General Provisions B Organization and Personnel C Buildings and Facilities D Equipment E Control of Components and Drug Product Containers and Closures F Production and Process Controls G Packaging and Labeling Controls H Holding and Distribution I Laboratory Controls J Records and Reports K Returned and Salvaged Drug Products Biotechnology 101 Business and Regulatory Practices 32