Oggetto: Procedura di Gara per AFFIDAMENTO SERVIZIO DI

advertisement

®

TRASCO ES

TRASCO® ES: “0” Backlash Coupling

Contents

TRASCO® ES “0” Backlash Coupling

Page

Description

43

Advantages

44

ATEX 94/9/EC compliance

44

Technical characteristics - Misalignments

45

Installation and maintenance

46

Selection according to DIN740.2

47

Example for selection and load check

48

TRASCO® ES execution

49

• Standard type execution

50

• “M” execution with clamp hubs

51 - 52

• “A” type - shrink disc execution

53

• “AP” type - shrink disc execution according to DIN 69002

54

• “GESS” double cardanic execution

55

• “GES LR1” execution with intermediate shaft

56

• “GES LR3” execution with intermediate shaft

57

- Technical data for intermediate shaft couplings “GES LR1 - GES LR3”

58

www.sitspa.com

TRASCO® ES: “0” backlash coupling

TRASCO ® ES is our zero backlash coupling designed to

compensate for misalignment and vibration dampening for

indexing applications. The compact design of TRASCO® ES

makes it the right choice for all precise motion applications.

Description

The element is available in 4 different hardnesses: 80 Sh. A

(blue), 92 Sh. A (yellow), 98 Sh. A (red), 64 Sh. D (green).

Coupling performance depends on the type of element selected

(see “Technical characteristics” ).

Other element hardnesses are available upon request to

meet special operating conditions, such as high temperatures

and/or high torques, and for providing a high degree of vibration

dampening capability. Please contact our Engineering Office for

help in selecting the appropriate element hardness.

TRASCO® ES

The TRASCO® ES consists of two hubs, which are either made

of high-strength aluminum (up to the 38/45 size) or steel (from

size 42) that are connected with an elastic element.

The precise dimensional characteristics of TRASCO® ES are

obtained through our accurate machining process.

The special compound polyurethane elastic element, developed through extensive research and laboratory testing, is

made through a press-forming process which guarantees high

dimensional accuracy.

Spider

Hub

Operation

When the polyurethane element is installed in its special seats

between the hubs, it becomes precompressed, thereby providing

the zero backlash feature which characterizes the transmission

performance of this coupling.

With zero backlash, the coupling remains torsionally rigid within

the range of the precompression load, but does permit the

absorption of radial, angular, and axial misalignments as well as

undesired vibrations.

The significantly wide precompressed area of the flexible element keeps the contact pressure against the elastic element low.

Therefore, the element teeth can be overloaded many times

without undergoing any wear or taking a permanent set.

Direct Drives

43

www.sitspa.com

Advantages

The TRASCO® ES coupling provides the following advantages:

•

•

•

•

•

•

“zero-backlash” motion transmission

dampening (up to 80%) of vibrations from motor shaft

low heat and electrical conductivity

easy and fast installation

perfect balance (A & AP type)

low moment of inertia (due to compact design and types of materials used).

Main applications

TRASCO® ES couplings are most frequently used with:

•

•

•

•

•

servomotors

robotics

sliding tables

spindle controls for drilling and grinding mandrels

ball-bearing screws

Operating Temperature Range

The operating temperature range for the TRASCO® ES depends on the type of element. For the 92 Sh. A (yellow), the range is

between -40 and +90°C, and for the 98 Sh.A (red), the range is between -30 and +90°C. Peak temperatures as high as 120°C

can be tolerated for brief instances.

High operating temperatures can cause the elastic element to lose a considerable amount of elasticity, thus substantially lowering the

torque handling capacity.

Therefore, when selecting a coupling, the operating temperature must be carefully considered (see “Technical characteristics”).

ATEX 94/9/EC compliance

It is possible to ask for specific certification for use in hazardous area according to EC standard 94/9/EC. TRASCO® ES

couplings are available with specific mounting/operating

instruction manual and conformity.

For information, please contact our technical office.

T [°C]

Torsion angle [rad]

44

Direct Drives

www.sitspa.com

Technical characteristics

Shore

TKN

[Nm]

TKmax

[Nm]

80 Sh.A (blue)

0,7

7

92 Sh.A (yellow)

1,2

98 Sh.A (red)

9

14

19/24

24/28

28/38

38/45

42

48

55

65

75

CT stat.

[Nm/rad]

CT din.

[Nm/rad]

Cr

[N/mm]

∆Ka

[mm]

∆Kr

[mm]

∆Kw

[°]

1,4

8

26

114

0,6

0,15

1,0

2,4

14

43

219

0,6

0,10

1,0

2,0

4

2

69

421

0,6

0,10

1,0

80 Sh.A (blue)

1,8

3,6

16

52

125

0,8

0,20

1,0

92 Sh.A (yellow)

3,0

6

29

95

262

0,8

0,15

1,0

98 Sh.A (red)

5,0

10

55

155

518

0,8

0,10

1,0

92 Sh.A (yellow)

7,5

15

114,6

344

336

1,0

0,15

1,0

98 Sh.A (red)

12,5

25

171,9

513

604

1,0

0,09

0,9

64 Sh.D (green)

16

32

234,2

702

856

1,0

0,06

0,8

80 Sh.A (blue)

5

10

370

1120

740

1,2

0,15

1,1

92 Sh.A (yellow)

10

20

820

1920

1260

1,2

0,10

1,0

98 Sh.A (red)

17

34

990

2350

2210

1,2

0,06

0,9

64 Sh.D (green)

21

42

1470

4470

2970

1,2

0,04

0,8

80 Sh.A (blue)

17

34

860

1390

840

1,4

0,18

1,1

92 Sh.A (yellow)

35

70

2300

5130

1900

1,4

0,14

1,0

98 Sh.A (red)

60

120

3700

8130

2940

1,4

0,10

0,9

64 Sh.D (green)

75

150

4500

11500

4200

1,4

0,07

0,8

80 Sh.A (blue)

46

92

1370

2350

990

1,5

0,20

1,3

92 Sh.A (yellow)

95

190

3800

7270

2100

1,5

0,15

1,0

98 Sh.A (red)

160

320

4200

10800

3680

1,5

0,11

0,9

64 Sh.D (green)

200

400

7350

18400

4900

1,5

0,08

0,8

92 Sh.A (yellow)

190

380

5600

12000

2900

1,8

0,17

1,0

98 Sh.A (red)

325

650

8140

21850

5040

1,8

0,12

0,9

64 Sh.D (green)

405

810

9900

33500

6160

1,8

0,09

0,8

92 Sh.A (yellow)

265

530

9800

20500

4100

2,0

0,19

1,0

98 Sh.A (red)

450

900

15180

34200

5940

2,0

0,14

0,9

64 Sh.D (green)

560

1120

16500

71400

7590

2,0

0,10

0,8

92 Sh.A (yellow)

310

620

12000

22800

4500

2,1

0,23

1,0

98 Sh.A (red)

525

1050

16600

49400

6820

2,1

0,16

0,9

64 Sh.D (green)

655

1310

31350

102800

9000

2,1

0,11

0,8

92 Sh.A (yellow)

410

820

13000

23100

3200

2,2

0,24

1,0

98 Sh.A (red)

685

1370

24000

63400

7100

2,2

0,17

0,9

64 Sh.D (green)

825

1650

42160

111700

9910

2,2

0,12

0,8

92 Sh.A (yellow)

900

1800

38500

97200

6410

2,6

0,25

1,0

98 Sh.A (red)

1040

2080

39800

99500

6620

2,6

0,18

0,9

98 Sh.A (red)

1920

3840

79150

150450

8650

3,0

0,21

0,9

TRASCO ES

Size

TRASCO® ES

Even after operating for an extended period with a misalignment,

there is still zero backlash because the elastic element is only

stressed by pressure loads.

When an application causes a high degree of misalignment, a

double flexing type coupling can be provided which avoids the

formation of reaction forces.

Please contact our Engineering Office.

The following technical characteristics apply to all types of

TRASCO® ES couplings.

When using the M, A and AP versions, check the torque values

given in the table against the allowable hub transmission values

for the respective versions given in the pertinent sections.

TRASCO® ES couplings can withstand axial, radial, and angular

misalignment.

All the technical data in the catalogue are valid for rotation speeds of 1500 rpm and a working temperature of 30 °C.

For linear speed over 30 m/s, dynamic balancing is recommended.

Misalignments

Δ Kw

Δ Kr

Δ Ka

Axial

A ssia le

Angular

Disa ssa m e n t o a n g o la re

Radial

TKN

Coupling nominal torque

Nm

TKmax

Coupling maximum torque

Nm

CT

Torsional rigidity

Nm/rad

Cr

Radial stiffness

N/mm

∆Ka

Maximum axial misalignment

mm

∆Kr

Maximum radial misalignment

mm

∆Kw

Maximum angular misalignment

°

Disa ssa m e n t o ra d ia le

Direct Drives

45

www.sitspa.com

Installation and maintenance

1. Carefully clean the shafts

2. Insert the hubs onto shafts being connected. With the M, A

and AP versions, be sure to tighten the screws with the Ms torque value given in the catalogue. Be careful with the A and AP

versions to tighten the screws uniformally and crosswise to the

recommended torque

3. Position the element in one of the two coupling hubs

4. Fit together the two coupling halves, making sure the “s”

dimension is properly observed. This must be done to insure

proper elastic element function and long service life, as well

as to assure the coupling is properly insulated electrically

With the A and AP versions, mounting the hubs can be facilitated

by lubricating the shaft contact surfaces with an oil, but do not

use a molybdenum bisulphide based oils.

When mounting the TRASCO® ES coupling an axial thrust is

generated which disappears when the mounting has been com-

pleted to avoid putting axial loads on the bearings.

Note: All rotating parts must be guarded.

46

Direct Drives

Lubrication of the elastic element will reduce the amount of

axial force required during installation

www.sitspa.com

Selection in according to DIN 740.2

The coupling must be chosen so the applied working loads do not exceed the allowable values whatever the working conditions are.

1. Check the load with respect to the nominal torque

The nominal coupling torque must be greater than or equal to the nominal torque of the drive machine for all working

temperatures.

TKN ≥ TTKKN⋅ S≥θT⋅KS⋅DS θ ⋅ SD

TKN ≥ TK ⋅ S θ ⋅ SD

TKN

≥ TK≥⋅TS θ⋅⋅SSD⋅ S + T ⋅ S ⋅ S

TSK max

S

Z

θ

K

θ

D

TK max ≥ TS ⋅ S Z ⋅ S θ + TK ⋅ ST

θ K⋅ max

D ≥ TS ⋅ S Z ⋅ S θ + TK ⋅ S θ ⋅ SD

m

1

m

1

m

1

(1)

(1)

(

1

(1)

)

(1) T

(1)

≥ TSS⋅=⋅ STZT

⋅S

+T

SAθ +⋅ S

≥ T⋅ S ⋅ S Z ⋅⋅ S

SSmax

Motor-side peaks: TTSK max

Driven-side

⋅⋅ S

⋅ ⋅S

= TLS ⋅⋅ SL + T⋅ S

+ TL

θT

K

TS = TT

= TAS

TKL ⋅ S θ ⋅TKT

⋅TT

⋅TSDL +peaks:

TL

D= TT

SθA ++ T

AS

LSS ⋅

L L

≥ TS ⋅ S

++

SZ ⋅=

LS

K max AS

θA+

KL ⋅ S θ ⋅ SLD

m

1

m

+

1

m

+

1

m

+

1

m +1

m

+

1

TK max ≥ TS ⋅ S Z1 ⋅ S θ + TK ⋅ S(1θ) ⋅ SD

m

(1)

1

(1)

(1)

(1) m

(1)

= TAS

⋅ 1 T⋅ S⋅=ST

+ ⋅T

= TLS

⋅m ⋅ S⋅ S+L T

+T

L

A T

L

TS = TAS ⋅

⋅ SA + TL TST=S T

⋅ SL + TL TST=S T

S

LS ⋅

L

L

AS ⋅

A +LS

L

m

+

1

m

+

1

3. Check the load with respect to

torque

inversions

m1+periodic

1

m

+1

m +11

mm

+1

(1)m

(1)

(1)

(1)

1+

) T

= TAS

⋅max

T⋅ ⋅KS

⋅ m ⋅ SL + TL (1)

T+LS

⋅ S⋅DS

≥1TT⋅ S=⋅AθS

SLD TST = =TLS

≥TKT

S

TTKSmax= T

≥ASTS⋅ ⋅ S Z ⋅ S⋅ S

+

TKT⋅LS θ T

⋅T

S

ST

LT⋅θ (S

L θ+⋅T

A +

Z+

KDmax

S⋅ ⋅ S Z S⋅S⋅ S

θ ⋅K

θ

=

T

T

⋅

By means of resonance

+ 1 ⋅ SL + T(1L)

S

LS mm

S

AS m1+ 1

A

m +1

(m

1L) + 1

+ ⋅1SA + TL

+ ⋅1SL + TL

TS below

= TAS ⋅themoperational

TS = TLS ⋅ m

When the resonance frequency is passed rapidly

mwill

+ 1 be seen.

≥ Tm

+ T⋅KSinterval

⋅ S⋅θS⋅ SD a few torque peaks

T

≥ T ⋅ S ⋅ S + T ⋅ ST ⋅TSK max≥ T

⋅SS⋅+S1⋅ZS⋅ S+θ T

K max loads

S must

Z

θ

K

θ K max

D withSthe Zmaximum

θ

K torque

θ

D the coupling can support.

The generated alternating

be

compared

m

m

1 ⋅ S 1+ T ⋅(1S) m⋅ S (1)

1

(1)

(1)

(1)

≥ TSS⋅ =⋅ ST

SSmax

⋅LITLV⋅R⋅ S

+ T⋅LS

= TLI ⋅⋅ VR + T⋅ LV(1R) + TL

ZAI ⋅⋅T

θ =+

K

θ

D⋅ V + T

V

TS = TT

TTSK max

= TAI≥ ⋅TS ⋅ S Z⋅⋅VSRθ ++TTLK ⋅ S θT⋅TKT

TT

D= TT

≥ TS ⋅ S

⋅m

S

Rθ +

LI S⋅

S

R

L

K max AI

Z

K

θ

D

1 ⋅ Sm ⋅+S1

m +1 m +1

m +1

TK max ≥ TS m

⋅ S1+Z 1⋅ S θ ++ T

K (1) θ

(1)

mD

1

mm ⋅ V + T

1

(1)

(1)

(1)

(1)

V

T

T

=

T

⋅

⋅

+

T

=

T

⋅

Motor-side peaks: TS = TAI ⋅

L

⋅ VR + TL TS =S TAI ⋅AI m +⋅1VRTS+R =TDriven-side

⋅ Vpeaks:

TS =S TLI ⋅LI m +⋅1VR +R TL L

R + TL

LTLI ⋅

+1

m1+ 1

mm

+1

m +11

(1) mm

(1)

(1)

(1)

TT⋅ ≥LIS(θT

=D TT

⋅ V≥

TS = TLI ⋅ m ⋅ VR + TL (1)

TKN

⋅ VTRW+ ⋅TSL θ ⋅ STf 0S⋅T,S25

TRVST+KW

=

⋅1)⋅WS⋅f S⋅ S

⋅ ⋅VSR f +⋅ STDL

0KN⋅,25

T1KW

=T

0T,25

AI

S =T

AI ⋅= TKW ≥

KN =

θ D

W+ L

T

=

T

⋅

⋅

T

=

T

⋅

⋅

V

+

T

m

+

1

m

1

+

S

AI

R

L

S

LI

R

m

1

m +1

(1) m + 1

(1L)

TS = TAIinversions

⋅ m + ⋅1VR + TL

TS = TLI ⋅ m + ⋅1VR + TL

4. Check the load with respect to nonperiodic torque

m +1

0⋅,S

25

TKNm=+T1KW ≥ TW⋅ S⋅ S⋅θS⋅ S⋅ S

f ⋅ SD

0,25

TKN =toTKW

≥ TW ⋅ S θ ⋅torque

S,f25

0

T

Dinversions,

To check the load with

respect

nonperiodic

the

equations

must be satisfied:

KN = TKW ≥ T

W following

θ

f

D

T

≥

T

⋅

S

⋅

S

TKN ≥ T1

S

m

m

1 ≥KNT 1 ⋅ SK ⋅ Sθm⋅ SD

K ⋅ S θ ⋅T

,25

= =TKW

TAI

⋅W,S

TAIT

⋅⋅W≥VWT

θV

f

=TKN

T

TW = TTLIW⋅ = TLI ⋅⋅ Vfi ⋅ Vfi

T0W,25

=T

Vfi WD ⋅ S θ ⋅ S0T

⋅ θfi ⋅ S

⋅DV

KN⋅ = TKW ⋅≥

f0

D

W⋅ =

25

TTKN

T

⋅⋅ S

AI

fi=WTLI

KW

f ⋅ SDfi

+1

m

m

+

1

+

m

1

m

+

1

+

m

1

m +1

0,25 TKN

TKN=≥T1KW

T1K ⋅≥STθ W⋅ S⋅ DS θ ⋅ Sm

f ⋅ SD

1

mm ⋅ V

T

=

T

⋅

⋅

V

T

=

T

⋅

TW = TAI ⋅

⋅V

TfiW fi= TLI ⋅ ⋅ S ⋅ S⋅ Vfi+ T ⋅ S T⋅WSW= TLI ⋅LI m +⋅1Vfi fi

T W= TAI ⋅AI m +⋅T

V

TK max m

≥1

T+S1⋅ S Zfi ⋅ S θ + TKW⋅ S θ ⋅ S

K

θ

D

+1

mm

D m+

11 1K max ≥ TS m

m+Z 1 θ

1 ⋅TVWfi =Driven-side

TW = TAI ⋅

TW = TLI ⋅ m ⋅ Vfi

Motor-side peaks: TW = TAI ⋅

2

⋅ Vfi 2

⋅ Vpeaks:

2TLI ⋅

fi

T

=

T

⋅

⋅

V

T

=

T

⋅

+ 1 ⋅ Vfi

W

LI mm

W

AI m1+ 1 ψfi ψm

m1++1 ψ

≥1+T

+⋅S1V⋅ fiS1Z +

θ + TK+ ⋅1S θ ⋅ SD

⋅ S

TW = TTAIK max

⋅ m

TW = TLI ⋅ m + ⋅1Vfi

2π 2 acceleration. m + 1 2π2 2 2π 1

m +1

(1) TL to be added if a torque

m

(1) (1)

(1)

V(1) = Vfi =

1

Vfi = peak occurs2during

ψ T= T

2 T

2⋅ 2 m⋅ 2 + T

ψ

T

=

TS = TLS ⋅

⋅ SL + TL

S

TS= TAS12⋅+ ψ ⋅ SA +2TL fi

⋅

⋅

S

+

T

2

2

S

AS

A

L

+

1

nS ψLSm

L

L

+

1

ψ

n

ψ

n

m +1

m

++π1 2

1 − 12−π2+π 222 + +m1+ 1

1 −

2

m

(1)

2π 2 2(π1)

Vfi = nR12+2 ψ 2π VfiV=fi = T = T1n+R22⋅2ψ21n

ψ

⋅

+

T

T

=

T

⋅

⋅

S

S

R

2

S

LS

L + TL

A2

L

2ψπ+1ψ

ψ

n1+

Calculation coefficients n2 2π ψ 2

S1 −n2AS

m

m

+

1

2

Vfi = 1 − 2 2 + VfiV= = 1− 12+2 2+2+π

≥

≥nTS2 ⋅S Z ⋅ S

Tπ

⋅ S θ + TK ⋅ S θ ⋅ SD

n2RT

π2

TK max

+ T2K ⋅ Sfi θ ⋅ SD nn

2

π

2

K

max

S ⋅S

π

2

2Z

θ2

2

ψ

n

R

R

Torsional

rigidity factor

Sθ = Temperature factor

+D = ψ

ψ2

1 − 2 + Vfi = 1− 2n2 2S

n

1 −nn≥R T2 ⋅ S+⋅2ψ

π +T ⋅ S ⋅ S

2π

T

S

R

π

2

K1max

n2RSJA+ +ZJLJAθ +JJAKL −1 θ D−1

JA

30

J

− 30

30

JA + JL +80

T [°C] – 30 / +30

Positioning

and angular

CTooling

nR−1= nR =C

min min

m = Am = Speed

=

nR+40

C+60

min

=

machines

Tdin

nRπ

Tdin

Tdin

J2mπ

⋅1

m indicator (1)

acceleration

(1)

m

1A ⋅ JL

system

J

J

J

(1)

(

1

)

π

⋅

J

J

π

J

L T =L T ⋅

T A= TTL ⋅=A TLIL ⋅ ⋅ VR +⋅TVLR + TL

⋅ VR + TL

Sθ

1

1,2 TS = TAI1,4

⋅

⋅ V1,8

+ TL

LI

30

J+A 1+ JLR

JA1−1m−1+ 1

3030 C JASJ+A J+LJAISL m min

JAJA S

m

+1

+

−1=

m

n

m

=

R

Tdin

nR =

CTdin

m

=

=

nmin

C

min

m

=

10

≥

2-5 (1)

3-8

R

Tdin

m

(1)

AJ⋅JJ

π

π TπS = TAI ⋅JJAAJ1⋅+

⋅ LVR + TJJLLA−1

TS =JJLTAJLIL ⋅

⋅ VR + TL

Sν = Starting frequency factor

LL

JJAA +⋅ JJLL

30

−1 30

+

30

J

J

J

C

min

n

=

m

=

−

1

C

n

min

=

m

=

+

m

1

m

1

+

A

L

A

R

Tdin

R = T ⋅ S ⋅Tdin

TKKN

TKSJ⋅DJS=+

⋅JSD⋅ 1=,210

⋅=1,248

⋅ 4,0=[Nm]

48,0 [Nm] m =JJ

⋅ S=C

⋅4

==

min

nKN

TKN

,π0T

[Nm]

θ⋅ 10

θ ⋅Tdin

R48

30

πK θ SD J=A10

⋅ JL⋅ 1,2 ⋅ 4 T=

LLJ

LJ

A

L−1≥ T

0-100

101-200

S/h

JA J⋅T

TJKW

0,25 201-400

TKN = TKW ≥401-800

TW ⋅nSRθ =⋅ 801-1.600

S f ⋅ πSDCTdin 0A,SA25

L =min

L

KN

W ⋅ S θ ⋅ S f ⋅ SD m =

o SA = Shock factor

π T ⋅ S ⋅ SJA =L⋅ J10

JL

L ⋅ 1,2 ⋅ 4 = 48,0 [Nm]

T

=

θS =

D 10 ⋅ 1,2 ⋅ 4 = 48,0 [Nm]

SZ

TKN

⋅ SD = 10 ⋅ 1

,2 ⋅T4KN=KN=48

0⋅KS

[Nm]

1

1,2= TK ⋅ S θ1,4

1,6

TK,1,8

⋅

0,25θ TKND = TKW

≥ T of ⋅ impact

S θ ⋅ S f ⋅ SD

Type

S L o Sa

TKN

48,<0=TNm

<TW

T=

=T,48

0=Nm

TTKN ==48

,0⋅ SNm

< T=cal10 ⋅ 1,2 ⋅ T

KN=

cal ⋅ 1,2cal

⋅ ,S

10

⋅ 41= 48,0 [Nm]

T

⋅

S

4

48

KN

θ ⋅S

D

KN

K

θ

D1

m

TKN = K0TK[Nm]

⋅S

⋅

S

=

10

⋅

1

,

2

⋅

4

=m

48,0 [Nm]

θ

D

=TT

⋅Light

⋅ V,0fi [Nm]

TW = TLI ⋅

⋅ Vfi

S f = Frequency factor

1,5

TW = TAI ⋅

⋅ Vfi TKN = TK ⋅ S θ ⋅ SDT=

TLI=⋅ 48

⋅ Vfi

W 10

⋅W1AI,2=

⋅m

4

T

=

48

,

0

Nm

<

T

+1

m

+

1

m +1

TKN = 48,0 Nmm

< T+cal1

TKNKN= 48,0 Nm < Tcal cal

m

1 Medium

1,8

f in Hz

>10

≤10 JA

=Nm

⋅ Vfi

T =T ⋅

⋅V

JTAAI<⋅ T

JT

AW

TKN

m+=11,5 fi

KN

m

JA+mJ=2=J11,+5J2 JL = J3JL+ =J2J3 +WJ2m =LI 1,5

== =48

=

J

J,L0=,0

= Nm

J3 +<Jm

Jcal

m

= = 48,0 Nm <JATcal

= J1 + J2 Tm

m

1

TKN

48

T

A

1

2+

cal

J

Strong

2,2

J

JL

Sf

1

f/10

L

2

2 TKN = 48

JL ,0 Nm < Tcal

J

Jmm

=JA A J = J J+JJ=

= J+1 J+m

J21=+1,5ψJJ=L J= J+3 J+ J2

A J

m= A

mm

= 1=,51,5

J1A +=Jψ

+

=

L

3

2

L

3

2

1 2

A

1

2

JL

JJLAJL

2π 1

1

1

1

1

1

2

π

2

J

A =

== =

13,2 [Nm]

⋅ 1+,5

J⋅T

,2J=[Nm]

VAS

⋅S

1,SJ5⋅===T13

2

[Nm]

,0 ⋅mTS= = T

Tm

m = 1,5

J⋅+⋅AfiS

J ⋅22

+SJ,02=⋅ =22

1,,520 ⋅ ⋅J1L,J5===J13

JAS,V

JAA == J222

A

AS

fi ⋅

S = T

1 + J2 m

m = 1,5

JJA1A2++=11J1ψ+Am

+ 13J2 3 + 2J2

1,5+2=JJ1AL L m +31 m

Jn212,5+ 11,5

L

JL m + 1 n2

ψ

ψ

J

m = 1,5

=1 L 1 1 JA = J1+21π

J−2 12 1 + JL = J3 + J2

1 − 2 + mfactor

1

=

VTfi ==Torque-Amplification

=

V

=

⋅

⋅

=

⋅

⋅

=

T

T

S

22

,

0

1

,

5

13

,

2

[Nm]

fi ,5 = 13

2π13

,2A[Nm]

TAS ⋅ ⋅ nSRA =

⋅1

⋅S

=A 222,0 ⋅ n ,5 +2⋅11,5 =

,2 [Nm]

L ⋅AS

T2⋅Sπ=S TJAS

S

22,0

1,51+ 1 mm

m1+ 1

+11+ 1 n2 1,5R1

+ 1

ψ1

−

1

+

1

1

T⋅K⋅S4⋅DS==θ 85

==T13

⋅13

1S,5,2==⋅ 113

,⋅,22

⋅22

⋅ 1,+612

⋅ 1,2 + 12,5 ⋅ 1,2 ⋅ 4 = 85,34 [Nm]

S

13

=T⋅K1T

,613

1,,2[Nm]

2

TT

TS⋅ ⋅ S Z ⋅ S⋅ θS+A T=K 22

SST

,⋅2

,=613

,5⋅θ,S

,θ⋅2

⋅ S,θ0⋅T

⋅ ⋅1S,,S

++=12

⋅0+1,0

⋅T

=S

,5

22⋅θAS

[Nm]

TAS

2T

AS

max

T

KDmax

S⋅⋅⋅1

Z

K max

S ==

,5 =[Nm]

[Nm],5 ⋅ 1,2 ⋅ 4 = 85,34 [Nm]

π+1 ⋅ ,1D34

nRAZ =K22

1⋅,251

1+ 1

1,5S +=1TAS m

m +1

⋅S

TS = TAS ⋅ m + ⋅1S A = 22,0 ⋅ 1,5 + ⋅11,5 = 13,2 [Nm]

= T,⋅2

+12

= 85

+ 12

= 85

TSK max= 13

TK,5⋅ S

13

21,⋅61[Nm]

,⋅61,⋅21,+212

4 85

,34

[Nm]

+S⋅1ZS⋅⋅1S

+

m

S ⋅⋅1

θ,1

D1

TK max = TS ⋅ S Z ⋅ S θ + TK ⋅ ST

2⋅,D5S

⋅ 4=

=

+θ +T

T

13

,2,,⋅34

,5 ,⋅51,⋅21,⋅24⋅ =

,34

[Nm]

θ K⋅ max

D

S S

Z,6

θ,2

K ⋅S

θ⋅ ⋅1S

30

JJA A+ JL

J

30

J

J

+

−1

−

1

A

L

m

=

Mass

factor

=

nR = Resonance frequency

=

n

min

m [Nm]

= A

TTK85

=,6⋅85

34

Nm

<C

T⋅,m

34

Nm

T12

TTK max n=R==85

< Tcal ⋅ S T⋅TS

min

=T ,34

R,,2

Tdin

max

cal⋅=

K

max

cal⋅,S

==13

⋅ ,S

+<+T

=

⋅

⋅

+

⋅

⋅

=

S

S

13

,

2

1

,

6

1

,

2

12

,

5

1

,

2

4

85

,

34

,

2

1

1

5

1

2

4

85

,

34

[Nm]

⋅ S ZNm

⋅CSTdin

=

⋅

⋅

⋅

=

K

max

S

Z

θ

K

θ

D

K max

Sπ

θ +T

K

θ

D

JL ,2 ⋅ 1,6 ⋅ 1,2 + 12,5 ⋅ 1,2 ⋅ 4 = 85,34 [Nm]

JL

JA ⋅ JL TK max = TS ⋅ S Z ⋅ S θ +πTK ⋅ S θ ⋅ SDJJA=L ⋅13

30⋅ S + T J⋅AS+ ⋅JS

JA ,34 [Nm]

⋅S

TKTmax =n=TS85

13,2−1⋅ 1,6 ⋅ 1,2 + 12,5 ⋅ 1,2 ⋅m

4 == 85

Z Nm

θ

K

θ L D =min

=

C

,

34

<

T

R ,34 Nm < Tdin

K max

TK max = 85,34 Nm < Tcal TK max

= 85

Tcal cal

π

JA ⋅ JL

JL Direct Drives

47

TK max = 85,34 Nm

<

T

TK maxT= 85

,

34

Nm

<

T

cal

cal

T

85,0,34

Nm

< Tcal

,2K ⋅max

4 ==48

[Nm]

KN =

K ⋅ S θ ⋅ SD = 10 ⋅ 1,2 ⋅ 4 = 48,0 [Nm]

KN = TK ⋅ S θ ⋅ SD = 10 ⋅ 1T

[

[

[

[ []

[[ ]]

[[ ]]

[ ]

]

]

]

[

]

[

]

[

]

]

TRASCO® ES

2. Check the load with respect to the torque peak

TKN

≥values

TK ⋅ S θ ⋅ SD

TKN ≥ TK ⋅ S θ ⋅ SD

TKN

≥T

K ⋅ S θ ⋅ SD

The maximum coupling

torque

must

be

greater

than

or

equal

the ⋅ torque

occur during operation for all working

S + TSpeaks

⋅DS θ ⋅ Sthat

⋅to

TTK max≥≥TTS⋅ S

⋅ S Z⋅ S⋅ S θ + TK ⋅ S θ T

⋅T

SKDmax

SS⋅θS+Z T

D

K ⋅θ S θ ⋅ K

≥ T≥TK⋅Tmax

SS θ⋅ S

⋅≥SZT

KN

D

KN

K

θ

D

temperatures.

TKN ≥ KTK ⋅ S

⋅

S

θ

D

KN

K

θ

D

TKN ≥ TK ⋅ S θ ⋅ SD

≥ ⋅TSS θ≥

⋅S

⋅K⋅SS

T

≥TT ⋅ S

+ ZT

⋅S

θZ+

S

⋅S

θ⋅ ⋅S

≥TSKTD⋅+S⋅TθSK⋅Z⋅⋅SS

⋅DSθ θ+

+TDTK⋅ S

⋅ S θ⋅ S

⋅ SD

TK max K≥max

TS ⋅ SKZSmax

⋅ STθKZmax

+ TK ⋅TS

⋅S

K

max

TST

θ max

D≥ TθS S⋅ S Z

K

θ

K

θ

D

www.sitspa.com

Example of selection

T

S

m (1)

1 1

m

1

(1)

(1)

(1)

(1)

1 (1) TS =(1)(T

1) m

TL⋅ +1T

T = TTLS=⋅⋅STL (1+)⋅ TT⋅Lm

SL +⋅ S

TL +mm

)⋅ T⋅LSA +

T = T T1 ⋅ = TSAS=⋅⋅S

T

⋅

TL ⋅ SL + T(L1)(1)

LS S⋅ ⋅ S

A (1+

S

T

=

T

⋅

+

T

S

LS

AS

A

L

S

= TSAS ⋅ AS S m⋅ TS

+

T

T

=

T

⋅

+

T

S==TTLS⋅L⋅

⋅ SL + TL

+A1 mL +T1SmS=+T1ASAS⋅ m + 1⋅ SS A A+ TLSL L

m +L1 mL +T1m

+

1

S

LS

m +1

m +1

m +1

mm++11

≥ ⋅TSS θ≥

⋅S

⋅K⋅SS

T

≥TT ⋅ S

+ ZT

⋅S

θZ+

S

⋅S

θ⋅ ⋅S

≥TSKTD⋅+S⋅TθSK⋅Z⋅⋅SS

⋅DSθ θ+

+TDTK⋅ S

⋅ S θ⋅ S

⋅ SD

TK max K≥max

TS ⋅ SKZSmax

⋅ STθKZmax

+ TK ⋅TS

⋅S

K

max

TST

θ max

D≥ TθS S⋅ S Z

K

θ

K

θ

D

Application

m m

1 (11)

m

1

(1)

(1)

(1)

(1)

(1)

m

TL +1T1 (1) ⋅ V + TT

TLI ⋅=⋅VT

(1+

) ⋅ T⋅L VR +⋅ V

T = T 1T⋅ = TTSAI =

⋅⋅VTRAI(1+)⋅ TT⋅L V

mm

R +⋅ V

L +

(1)S = TLIT⋅S = T

TL ⋅ VR + T(L1)(1)

R LI

TS==TTT

L ⋅V T

S+ T

TS = TSAI ⋅ AI Sm⋅ V

=

⋅

V

S==TTAI⋅R⋅

R+S T

LTLI ⋅

LI⋅R⋅

m

+

1

mL + T

1m

T

⋅ VR + TL

R1+ T

R

L

m

+

1

+

m

+

1

+

1

S

AI

R

L

S

LI

m

+

m

+

1

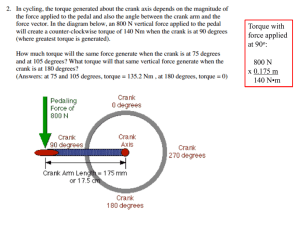

Servomotor driving a recirculating ball screw

m +1

m + 1 on a machine toolm + 1

m + 11

TK =0,25

10,0

Shock

Type

,25

TW

T 0Nm

= T0T

⋅0S≥,T25

S≥f ⋅⋅S

f θ⋅ S

,KN

25≥=TTT

TSθ=D⋅T

⋅SS

⋅≥SDTf W

⋅ S⋅DS θ ⋅ S f ⋅ SD

KW

WKW

θ ⋅S

KN

0T,25

T22,0

= KN

TNm

⋅=S

KN W

KW

,25

TDT

KW ≥ TW ⋅ S

θ0

f ⋅KW

Table

Moment

Inertia

AS = KN

KN = T

KW ≥ T

W ⋅ S θ ⋅ Sof

f ⋅S

D

Nominal Torque

Peak Torque

Rpm

Moment of Inertia

Temperature

Light

J3 = 0,0038 kg·m2

dc = 20 mm h6 (without keyway)

dm = 24 mm h6 (without keyway)

n = 3.000 1/min

Driven Shaft

J1 = 0,0058 kg·m2

Motor Shaft

m

1 1

m

1

T =TW+40°C

1 = TAI =

T ⋅ =TTLI ⋅=⋅VTfi ⋅ T⋅m

Vfi ⋅ V mm ⋅ V

= TT

⋅⋅VTfi AI ⋅ T⋅ V

TW = Tm

11 ⋅ T

fi= T

⋅

V

LI W

AIW⋅ ⋅T

⋅

V

W

W

fi

TW = T

⋅

V

=

T

⋅

⋅

V

⋅ V Wfi

⋅ V fi

LI

AI

m +fi1 m +T1 W= T AI⋅

m +fi1 mLI+T1 W==TTLI⋅fi⋅

m + 1 AI

m +1

Selection

W

mm++11

m +1

fi

W + 1 LI

m

mm++11

fi

2

2

2

2

2 ψ ψ

1ψ+ 1+ 1 + ψ 1 + ψψ 2

1

+

2π ( 98

24/28 “A” type ES coupling with “Red” elastic element

Sh.

A ) 1+

2π

Vfi = Vfi =V2fiπ= 2 V 2 = 2π 2 22ππ

Vfi = Standard

2 fi= 22 2

2

V

2

coupling

torque:

2

n2fiψn ψ 2Tψ2KN222= 60 [Nm]

n12− n 1−ψ

n ψψ 2

2− + +

+torque:

n

1

2

T

=

120

[Nm]

1 − Maximum

−

1

+

R 2πn 2 12−π 22πKmax

2 +

n 2 nR+ 2n

22ππ

R nn

R = 0,000135

R

Hub

Moment

ofπInertia:

[kg·m2]

RJ2

Couple Transmitted by taper locking ring:

Tcal =

{

92 [Nm] bore 20 [mm]

113 [Nm] bore 24 [mm]

30 JA30+ JL JA +30

J

30

JA

−1

JJL −+1 Jmin

1L

L JJA++J−J

J−1A−=

m = mA = JA m =JJA A

1

n30= nR =CJnTdin

m

−min

1 A

A +=JLC TdinnC =30

Amin L

C

min

R

Tdin

nR = R

C

min

m

=

Tdin

JL J m = J

min

π Tdin π JAπ⋅ JnLR RJ=A ⋅ JπJL A C

JL

⋅ JTdin

L

L

π

JA ⋅ JL

JL

π

JJA A⋅ J⋅ LJL

JL L

[ [ ] ][ [ ] ] [[ ]]

Load check

⋅S

⋅ ⋅SS

==⋅10

⋅ 1,48

2

[Nm]

T = TT

⋅ S= ⋅TSD=

=Tθ10

⋅D1θ,2

4DT==

0⋅1S

[Nm]

,=

2D⋅48

4= ,10

=0 48

S⋅θ,⋅4

⋅ 1,02 ⋅[Nm]

4 = 48,0 [Nm]

TKN = KN

TK ⋅ S θK ⋅KNSDθT=KNK10

⋅ 1K,2T

⋅T

4KN=⋅ S

48

,K0⋅10

[Nm]

KN = TK ⋅ S θ ⋅ SD = 10 ⋅ 1,2 ⋅ 4 = 48,0 [Nm]

TKN

48<,=0T48

Nm < Tcal

T = 48

,0 =

Nm

<48

Tcal

cal ,0TNm

Nm<<TTcal

TKN = KN

48,0 Nm

<TTKN

TKNKN==48

,0,0Nm

cal

cal

m=

J

J

JA = A m = mA = JJAA = J1 J+A J=JA2 AJJ1 += JJ2 +

,5J= 1,5 m = 1,5

+ Jm

1,5m = 1m

m

23 +=J

= A JL =1 JJJL3JJ=2+A=JJ=32JJJ+L1+J+=J2 JJJ2m

L3 ==J1

,5 JLJ2L==J3J3++

JJAL = JJ1 +m

Jm

m = 1,5

J2 2

2=

JL

A

1

2

J

L

JL

JL L

1 1

1

1 1 1 1

0 ⋅⋅ 1,,50⋅ S

[Nm]

⋅ S,01⋅=⋅ S22

⋅=1,2522[Nm]

=⋅,1

T = T T1 ⋅ = TSAS=⋅⋅S

= 13

,5⋅ ,=211

13

,2⋅ 1[Nm]

⋅ T22

A ,=

013

13

[Nm]

⋅+,,=

AS

A

TS = TSAS ⋅ AS S m⋅ T

S+A1 =T

22

0

51122

,A⋅21

[Nm]

⋅S=+=AT1T

⋅

=113

AS

A=

m

1Sm

,

5

1

+T

+

S

22

,

0

,2,2[Nm]

⋅1

⋅

⋅

⋅ 1,5,5==13

1,5

,

5

1

+

AS

m +1

1,5 + 1 mm++11

1,15,5++11

= ⋅TSS θ=

⋅S

⋅K⋅SS

⋅ SS

⋅S

⋅ 11,85

⋅⋅,⋅4

TSKTD⋅+S

13T

1

1

,52,6⋅+

12

,4,+

52=12

=TT ⋅ S

+ ZT

⋅S

=⋅TθS13

⋅ 1,=2

+,612

T

,2 ⋅=1

,S

,2⋅13

,1

1⋅,1

2

34

[Nm]

θZ+

⋅,2

⋅2

⋅85

,2⋅85

,5[Nm]

,=2+

412,=34

θ⋅ ⋅S

+6

⋅⋅,S

=

⋅[Nm]

= 85,34 [Nm]

,26

11,2

,585

1,34

2 ⋅ 4[Nm]

θ S⋅ ,S

⋅ STθKZmax

+ TK ⋅TS

⋅S

=13

TK max K=max

TS ⋅ SKZSmax

2ZK⋅ 1Z⋅⋅,S

6⋅DSθ⋅θ1θ+

,θ5θ⋅,⋅2S

1

,⋅34

K

max

K⋅ S

D⋅ 4

TST

TD+K 12

θ max

D==T13

K

S

D = 13,2 ⋅ 1,6 ⋅ 1,2 + 12,5 ⋅ 1,2 ⋅ 4 = 85,34 [Nm]

85,=34

Nm

<Nm

Tcal< T Nm < T

T

=T85,34

Nm

< Tcal

TK=<max

,K34

cal

TK max K=max

85,34K max

Nm

Tcal 85

max = 85,34

cal

TT

K max = 85,34 Nm < Tcal

TKN

Coupling nominal torque

Nm

nR

Resonance speed

min-1

TK

Motor-side nominal torque

Nm

CT

Torsional rigidity

Nm/rad

TKmax

Coupling maximum torque

Nm

MT

Transmissible torque moment

Nm

TS

Motor peak torque

Nm

SA

Motor-side shock factor

TAS/TAI Driver-side peak torque

Nm

SL

Driven-side shock factor

TL

Nm

SZ

Start frequency factor

Nm

Sθ

Temperature factor

Acceleration delivered torque

TLS/TLI Driven-side peak torque

VR

48

Resonance factor

Vfi

Torque amplification factor

m

Mass factor

JA

Motor-side inertia

JL

Driven-side inertia

Ψ

Dampening factor

Direct Drives

(∆ Kw) (∆ Kw)

Torsional

rigidity

SD(∆ Kw)

Kw) factor

(∆ Kw)

(∆(∆Kw)

kgm2

kgm2

Sf

Frequency factor

TW

Torque with reversal of the machine

TKW

Torque with reversal transmissible by the coupling

Nm

TCal

Hub-shaft connection maximum torque

Nm

Nm

www.sitspa.com

TRASCO® ES executions

FINISHED BORE HUBS EXECUTION

GES F C execution

Hub execution with finish bore,

keyway and setscrew. Not suitable

for backlash free drives with high

reversing frequency or high startup frequency.

Hub execution with finish bore,

and setscrew.

CLAMP HUBS EXECUTION

GES M execution

GES M execution

Clamping hub execution with single slot without keyway. Up to size

19/24. Backlash free hub design.

Transmissible torque depends on

bore diameter.

GES M...C execution

Clamping hub execution with double slot without keyway. From size

24/28. Backlash free hub design.

Transmissible torque depends on

bore diameter.

GES M...C execution

Camping hub execution with single

slot and keyway. Up to size 19/24.

The clamping pressure eliminates

backlash in torque reversals.

Camping hub execution with double slot and keyway. From size

24/28. The camping pressure

eliminates backlash in torque

reversals.

GES 2M execution

Split camping hub execution for

radial assembly of the coupling

Torque depends on bore diameter.

Execution “C” with keyway, as option

can be delivered for a positive torque

transmission with zero backlash.

These executions are suitable for

double cardanic applications.

SHRINK DISC EXECUTION

GES A execution

GES AP execution

Execution with locking ring. This

execution is suitable for high

speed and high torque. Screws

mounting from spider side.

Transmissible torque depends on

bore diameter.

Execution with locking ring with

high machining accuracy: design

suitable for application on spindles

according to DIN 69002.

Direct Drives

49

TRASCO® ES

GES F execution

www.sitspa.com

Standard type

SIT coupling hubs are available from stock with either solid hub

or with finished bores of standard shaft diameters.

The setscrews of our finished bore execution are positioned 120

degrees from each other with one positioned 180 degrees from

the keyway. Both the solid hub and bored hub coupling are generally available from stock for quick delivery.

Approved according to EC standard ATEX 94/9/EC.

L

L

t

t

C

S

S

I

F

min

[mm]

W [kg]

S

M

Fig. 1

I

Fig. 2

Fig .4

Hub

F

max

[mm]

N

I

J [kgm2]

nmax

[min-1]

A

[mm]

G

[mm]

L

[mm]

I

[mm]

22

7

8

6

10

8

M

[mm]

N

[mm]

S

[mm]

P

[mm]

c

t

[mm]

Fig.

1,0

6

M3

3,5

1

1,0

2

M3

5

1

ALUMINUM HUBS

ALUMINUM HUBS

7

3

7

0,003

0,085 x 10-6

40.000

14

-

9

4

9

0,009

0,49 x 10

28.000

20

7,2

30

10

-6

14

4

15

0,020

2,8 x 10

19.000

30

10,5

35

11

13

10

1,5

2

M4

5

2

19/24

6

24

0,066

20,4 x 10-6

14.000

40

18

66

25

16

12

2,0

3,5

M5

10

2

24/28

8

28

0,132

50,8 x 10-6

10.600

55

27

78

30

18

14

2,0

4

M5

10

2

28/38

10

38

0,253

200,3 x 10-6

8.500

65

30

90

35

20

15

2,5

5,2

M6

15

2

38/45

12

45

0,455

400,6 x 10-6

7.100

80

38

114

45

24

18

3,0

5,6

M8

15

2

-6

STEEL HUBS

60

t

C

126

50

26

20

105

51

140

56

28

21

60

160

65

30

22

4,0

68

185

75

35

26

4,5

80

210

85

40

30

5

6.000

2,520

3.786 x 10

5.600

9.986 x 10

5.000

120

18.352 x 10-6

4.600

135

160

25

70

65

25

80

5,900

75

30

ØG

ØF

ØA

55

95

46

2.246 x 10-6

°

4,100120

P

95

2,000

6,900

-6

-6

27.464 x 10-6

L

t

C

I

Order form

N

M

S

S

I

N

I

20

2

M8

25 0°

2

2

t

I

12

9

M10

20

8,3

M10

20

2

8,3

M10

25

2

N

M

S

I

Fig .3

Fig .4

GESF

24/28

F20

L

t

Size

t

C

F...: bore diameter

P

ØA

ØG

Spider

AES 24/28

R

TRASCO ES spider

Fig. 1S

N

I

M

B: 80 Sh A (blue)

G: 92 Sh A (yellow)

R: 98 Sh A (red)

V: 64 Sh D (green)

L

t

Fig. 2

S

I

2

Fig .5

210207/ 1/ C L

Direct Drives

P

M8

6C

I

GESP: solid hub

GESF: bore + keyway + set-screw

50

5,6

3,5

S

210207/ 1/ C L

S

M

Fig .3

Hub

Size

t

P

3.700

Bore tolerance: H7 - JS9 (DIN 6885/1) keyway

S

L

3,0

ØF

t

55

Øa

48

20

L

ØA

14

ØG

ØF

42

ØG

ØF

ØA

STEEL HUBS

ØA

M

Fig .3

Size

P

ØG

N

S

ØA

ØG

ØF

ØA

P

I

C

0°

12

ØG

ØF

t

C

t

W

Weight

kg

J

Moment of inertia

nmax

Maximum rpm

kgm2

min-1

www.sitspa.com

“M” execution with clamp hubs

This type of coupling permits quick, positive mounting, without

any shaft-hub backlash.

With the keyless coupling type, the torque applied for tightening

I

I

I

S

S N

I

I

I

f

Fig .7

Fig .7

Keyway

position

A

[mm]

G

[mm]

L

[mm]

0,085 x 10-6

40.000

-

14

-

22

7

8

6

1,0

6

4

15,0

1

0,007

0,42 x 10-6

28.000

-

20

7,2

30

10

10

8

1,0

2

5

23,4

1

10,5

9

M2,5

0,75

14

6

15

M3

1,4

0,018

2,6 x 10

19.000

180°

19/24

10

20

M6

11

0,071

18,1 x 10-6

14.000

120°

40

18

24/28

10

28

M6

11

0,156

74,9 x 10-6

10.600

90°

55

28/38

14

35

M8

25

0,240

163,9 x 10-6

38/45

19

45

M8

25

0,440

42

25

50

M10

70

48

25

55

M12

55

35

70

65

40

80

2 L 5,5

11

13

10

1,5

32,2

1

66

25

16

12

2,0

3,5

12

t

45,7

1

27

78

30

18

14

2,0

4

12

56,4

2

30

90

35

13,5

72,6

2

80

38

114

45

16

83,3

2

N

I95

M

S46

126

50

26

20I

M

3,0

78,8

2

105

51

140

56

28

21

3,5

6

21

108,0

26

122,0

2

27,5 139,0

2

90° P 65

90°

ØG

E

P

ØF

ØA

ØF

ØA

8.500

L

35

t

ØG

E

L

30Lt

-6

P

t

20

15

2,5

P

5,2

24

18

3,0

5,6

-6

465,5 x 10

7.100

2,100

3.095 x 10-6

6.000I

M-

120

2,900

-6

5.160 x 10

5.600

-

M12

120

4,000

9.737 x 10-6

5.000

-

120

60

160

65

30 f

22

4,0

9

M14

190

5,800

17.974 x 10-6

4.600

-

Fi135

g .6

68

185

75

35

26

4,5

8,3

N

S

S

I

STEEL HUBSS

I

E

S

E

STEEL HUBS

f

N

S

I

Fig .6

S

I

5,6

N

M

S

20

I

Fig .7

2

ØA

ØF

4

E

9

ALUMINUM HUBS

ØG

0,003

Fig.

E

0,35

ALUMINUM HUBS

E

M2

ØG

7

I

M

N

S

P

t

E

[mm] [mm] [mm] [mm] [mm] [mm] [mm]

E

3

J [kgm ]

ØA

ØF

7

W [kg]

2

ØA

ØF

f

f

Fig .7

From size 7 to 19/24: single slot execution

From size 24/28 to 65: double slot execution

Bore tolerance: F7 - JS9 (DIN 6885/1) keyway

210207/ 2/ C L

Hub

GESM 48

210207/ 2/ C L

F50

GESM: TRASCO ES hub

Size

F...: bore diameter

F...C: bore diameter and keyway

Spider

AES 24/28

R

Fig. 1

TRASCO ES spider

Fig. 2

210207/ 2/ C L

210207/ 2/ C L

Size

B: 80 Sh A (blue)

G: 92 Sh A (yellow)

R: 98 Sh A (red)

V: 64 Sh D (green)

I

Fig .8

nmax

[min-1]

F

max

[mm]

MS

Screw tightening torque

Nm

W

Weight

kg

J

Coupling moment of inertia

nmax

Maximum rpm

kgm2

min-1

Direct Drives

P

S

S

M

f

f

ØG

ØA

ØF

ØG

E

N

M

Fig. 2

Hub

F

min

[mm]

MS

[Nm]

I

Fig .6

Fig .6

Size

ØA

ØF

M

f

Fig. 1

S

S

TRASCO® ES

M

N

P

E

S

ØG

ØG

ØEA

ØF

ØG

E

I

S

t

P

E

M

I

N

E

I

S

S

E

N

P

L

t

t

P

ØF

ØA

ØF

ØA

S

L

L

t

t

ØE

A

ØF

L

L

P

down the screws (Ms) must be as given in the table.

The M coupling type is available with or without keyway.

Approved according to EC standard ATEX 94/9/EC.

51

f

www.sitspa.com

Using hub execution M without keyway, the maximum transmissible torque is the minor between the clamp-hub transmissible

torque and the value stated in the section “Technical

characteristics”.

Recommended M coupling Type Hub Bore Dia. [mm] and Transmissible Torque [Nm], valid for shaft tolerances k6

Size

∅4 ∅5 ∅6 ∅7 ∅8 ∅9

∅ 10 ∅ 11 ∅ 12 ∅ 14 ∅ 15 ∅ 16 ∅ 19 ∅ 20 ∅ 22 ∅ 24 ∅ 25 ∅ 28 ∅ 30 ∅ 32 ∅ 35 ∅ 38 ∅ 40 ∅ 42 ∅ 45 ∅ 48 ∅ 50 ∅ 55 ∅ 60 ∅ 65 ∅ 70 ∅ 75 ∅ 80

7

0,7 0,8

1

1,1

9

1,1 1,4

1,7

1,9

2,2

2,5

2,8

3

2,5

2,9

3,3

3,7

4,1

4,6

5

5,8

6,2

6,6

19/24

23

25

27

32

34

36

43

45

24/28

23

25

27

32

34

36

43

45

50

54

58

62

66

79

83

91

100 104 116 124 133 145

79

83

91

100 104 116 124 133 145 158 166 174 187

14

28/38

38/45

57

63

42

217 243 261 278 304 330 348 365 391 417 435

48

299 335 359 383 419 455 479 503 539 575 599 659

55

356 387 407 428 458 489 509 560 611 662 713

65

52

558 586 628 670 697 767 837 907 976 1046 1116

Direct Drives

www.sitspa.com

“A” type - Shrink disc execution

This type of coupling provides excellent kinetic uniformity.

Furthermore, the absence of keys or set screws makes it a

well-balanced coupling and greatly facilitates installation and

removal. An exact radial/axial positioning is easy for those

applications which require it. The absence of keyways also avoids

L

fretting corrosion and backlash between the shaft and the hub.

This is the ideal type of coupling for applications requiring precision and/or high rotational speeds.

Approved according to EC standard ATEX 94/9/EC.

L

ØF

ØA

f

f

ØF

ØA

ØF

ØG

ØF

ØG

P

P

S

N

I

f

f

S

M

I

Size

F

min

[mm]

F

max

[mm]

S

N

M

I

Screws

MS

per

locking [Nm]

elements

f

Hub

W [kg]

nmax

[min-1]

J [kgm2]

A

[mm]

G

[mm]

L

[mm]

I

[mm]

M

[mm]

N

[mm]

S

[mm]

P

[mm]

220207/ 1/ C L

ALUMINUM HUBS AND STEEL LOCKING ELEMENT

ALUMINUM HUBS AND STEEL LOCKING ELEMENT

14

6

14

M3

4

1,3

0,049

7 x 10-6

28.000

30

10,5

50

18,5

13

10

1,5

2

19/24

10

20

M4

6

2,9

0,120

30 x 10-6

21.000

40

18

66

25

16

12

2,0

3,5

24/28

15

28

M5

4

6,0

0,280

135 x 10-6

15.500

55

27

78

30

18

14

2,0

4

28/38

19

38

M5

8

6,0

0,450

315 x 10-6

13.200

65

30

90

35

20

15

2,5

5,2

38/45

20

45

M6

8

10,0

0,950

960 x 10-6

10.500

80

38

114

45

24

18

3,0

5,6

STEEL HUBS AND LOCKING ELEMENT

STEEL HUBS AND LOCKING ELEMENT

220207/ 1/ C L

42

28

50

M8

4

35,0

2,300

3.150 x 10-6

9.000

95

46

126

50

26

20

3,0

5,6

48

35

60

M8

4

35,0

3,080

5.200 x 10-6

8.000

105

51

140

56

28

21

3,5

6

55

38

65

M10

4

71,0

4,670

-6

10.300 x 10

6.300

120

60

160

65

30

22

4

9

65

40

70

M12

4

120,0

6,700

-6

19.100 x 10

5.600

135

68

185

75

35

26

4,5

8,3

Bore tolerance: H7

Using hub execution A, the shrink-disc maximum transmissible

torque is the minor between the value stated in the table

below and the value stated in section “Technical characteristics”.

Recommended A coupling Type Hub Bore Dia. [mm] and Transmissible Torque [Nm], valid for shaft tolerances k6

Size

∅ 10

∅ 11

∅ 14

14

10

12

22

19/24

42

46

60

24/28

∅ 15

∅ 16

∅ 17

65

69

74

79

84

66

72

77

82

87

175

255

28/38

38/45

∅ 18 ∅ 19

∅ 20

∅ 22

∅ 24

∅ 25

∅ 28

∅ 30

∅ 32

∅ 35

∅ 38

92

102

113

118

135

185

205

225

235

283

312

326

∅ 40

∅ 42

∅ 45

266

287

308

339

373

367

398

427

471

420

460

500

563

557

∅ 48

∅ 50

515

545

577

620

627

670

714

612

649

687

986

1112

1531

∅ 55

∅ 60

790

850

880

744

801

1140

1185

1284

1580

1772

1840

1960

∅ 65

∅ 70

840

932

1033

1412

1420

2049

1652

1680

1691

2438

2495

2590

88

42

48

55

65

Spider

Order form

AES 24/28

R

TRASCO ES spider

Hub

GESA 48

Size

F45

B: blue; G: yellow; R: red; V: green

GESA: TRASCO® ES hub - “A” execution

Size

F...: bore diameter

MS

Screw tightening torque

Nm

W

Weight

kg

J

Coupling moment of inertia

nmax

Maximum rpm

kgm2

min-1

Direct Drives

53

TRASCO® ES

S

I

www.sitspa.com

“AP” type - Shrink disc execution according to DIN 69002

Precision “zero-backlash” coupling designed for multi spindle

devices on machine tools or controls with reduced mass, such as

short center spindles, multi-centers primary spindles in work sta-

tions, or joined to high speed bearings with limited tolerance

range. It is suitable for very high speeds of rotation (up to speeds

of 50 m/s).

L

L

Ø F3

Ø F1

Ø F H6

Ø F2

Ø FH6

ØA

P

Ø F1

Ø F3

Ø F H6

Ø F2

Ø FH6

ØA

P

I2

S

N

I

S

M

I

Fig .10

I2

S

I

N

S

M

I

Fig .10

220207/ 2/ C L

Hub

FH6

MS

[mm] [Nm]

Size

W [kg]

nmax

J [kgm2]

[min-1]

A

[mm]

L

[mm]

I

[mm]

STEEL HUBS AND LOCKING ELEMENT

I2

[mm]

M

[mm]

N

[mm]

S

[mm]

P

[mm]

F1

[mm]

F2

[mm]

F3

[mm]

STEEL HUBS AND LOCKING ELEMENT

14

14

1,89

0,080

11 x 10-6

28.000

32

50

18,5

15,5

13

10

1,5

2,0

17

17

8,5

19/24 - 37,5

16

3,05

0,160

37 x 10-6

21.000

37,5

66

25

21

16

12

2,0

3,5

20

19

9,5

19/24

19

3,05

0,190

46 x 10

21.000

40

66

25

21

16

12

2,0

3,5

23

22

9,5

24/28-50

24

4,90

0,330

136 x 10-6

220207/ 2/ C L50

15.500

78

30

25

18

14

2,0

4,0

30

29

12,5

24/28

25

8,50

0,440

201 x 10-6

15.500

55

78

30

25

18

14

2,0

4,0

32

30

12,5

28/38

35

8,50

0,640

438 x 10-6

13.200

65

90

35

30

20

15

2,5

5,2

42

40

14,5

38/45

40

14,00

1,320

1.325 x 10-6

10.500

80

114

45

40

24

18

3,0

5,6

49

46

16,5

42

42

35,00

2,230

-6

3.003 x 10

9.000

92

126

50

45

26

20

3,0

5,6

54

55

18,5

48

45

35,00

3,090

-6

5.043 x 10

8.000

105

140

56

50

28

21

3,5

6,0

65

60

20,5

55

50

35,00

4,740

10.020 x 10-6

6.300

120

160

65

58

30

22

4,0

9,0

65

72

22,5

-6

Bore tolerance: H6

Spindle

98 Sh. A

TRASCO® ES

64 sh. D

“AP”

TKN

[Nm]

TKmax

[Nm]

TKN

[Nm]

TKmax

[Nm]

25 x 20

14

12,5

25

16

32

32 x 25

19/24 - 37,5

14

28

17

34

32 x 30

19/24

17

34

21

42

40 x 35

24/28 - 50

43

86

54

108

50 x 45

24/28

60

120

75

150

63 x 55

28/38

160

320

200

400

size

Spider

Order form

AESP 24/28

R

TRASCO ES spider - “AP” execution

Hub

GESAP 48

Size

F45

R: red; V: green

GESAP: TRASCO® ES hub - “AP” execution

Size

F...: bore diameter

54

Direct Drives

MS

Screw tightening torque

Nm

W

Weight

kg

J

Coupling moment of inertia

nmax

Maximum rpm

kgm2

min-1

www.sitspa.com

“GESS” double cardanic execution

This execution allows higher misalignments. The 2 spiders allow

a high vibration dampening providing a decrease in drive noise

and longer life of related components (ex. bearings).

The intermediate element is made of aluminum alloy and may be

used in combination with any type of hub execution.

V

H

N

M

N

S

M

C

H

Fig.1

Ø Fa

ØG

S

S

S

V

H

N

S

M

C

H

Fig .2

Fig.2

Fig .1

TRASCO® ES

M

S

Ø Fa

Ø Fa

ØE

ØG

ØE

Ø Fa

S

N

S

ØA

L

L

GESM...

7

3

4

14

9

20

–

V

[mm]

ALUMINUM HUBS

AES...

20

–

7

25

S

[mm]

4

GESM...

10

45

5

–

0,003

10

1

8

–

0,007

11

56

8

13

1,5

10

–

16

2

12

L

18

0,05

0,000013

1

14

27

0,14

15

30

0,22

18

38

3

20

21

30

3,5

H

4

22

H

60

0,97

C 0,002

35

Fig .1

4,5

26

68

1,43

0,004

–

42

25

92

10

24/28

10

28

55

–

52

30

112

16

18

2

28/38

14

35

65

–

58

35

128

18

20

2,5

38/45

15

45

80

–

68

45

158

20

24

3

48

25

60

105

85

M 80

55

25

70

120

H 110

65

25

75

135

115

S 50N

V

56

M

88 C

65

102

75

S

N 22S

192

M

24 V

252

Fig .1

M

28

32

S

1

0,00006

1

0,00013

1

0,35

0,00035

1

46

S 0,51

N

S 0,0007

S

N

51

0,67

M

V 0,001

M

S

H

S2

N

2

M

AES...

GE

GESS...

AES...

GESS: spacer element

GESM...

GESM...

GESM...

Size: 24/28

W

Weight

J

Coupling moment of inertia

kg

kgm2

280207/ 3/ C L

M

GESM...

AES...

AES...

V

N

2 Fig .2

AES...

24

S

C

AES...

GESS...

S

H2

GESM...

GESM...

AES...

GESS

S 26

N

H280207/ 3/ C LC

H

218

28

GESS...

Spacer element

L

ALUMINUM GESS

S

174

GESM...

Order form

ØG

40

ØE

ØG

Ø Fa

20

ØE

10

Ø Fa

19/24

N 74 S

1

0,024

34

75 S

GESM...

0,00000008

1

–

95

Fig.

0,0000004

L

0,000003

30

STEEL HUBS

J

[kg m2]

AES...

6

15

45

GESS...

1

6

20

G AES... W

[mm]

[kg]

8

14

42

N

[mm]

ALUMINUM GESS

34

L

M

[mm]

Ø Fa

9

7

L

[mm]

ØA Ø G

GESS...

H

[mm]

Ø Fa

C

[mm]

ØE

ØG

Ø Fa

E

A

[mm]

AES... [mm]

ØE

Size

GESM...

Fa max

[mm]

Ø FFaa

Ø

Fa min

[mm]

280207/ 3/ C L

Direct Drives

55

www.sitspa.com

“GES LR1” execution with intermediate shaft

This zero backlash execution, allows connection to long distance

shafts in applications such as lifting screw jacks, gantry robot etc.

The intermediate shaft is made of steel but may be of different

material for specific need.

The presence of 2 spiders, increases the dampening properties

and allow high misalignments.

L

H

H

N

A

S

dr

d

S

E

L2

M

A

LR1

LZR1

External hub

Size

Internal hub

Dimensions

finished bores

L

S

M

dmax

[mm]

N

E

H

L

M

N

s

L2

L2 [mm] [mm] [mm] [mm] [mm] [mm]

[mm]

Ms

[N·m]

MT [N·m]

LR1

[mm]

LR1

min

[mm]

LZR1

[mm]

dR x tightening

[mm]

A

S

M3x12

1,34

6,1

30

11

35

13

10

1,5

46,5

65

LR1+22

14 x 2.0

19/24

6

24

M6x18

10

34

40

25

66

16

12

2,0

80

85

LR1+50

20 x 3.0

24/28

8

28

M6x20

10

45

55

30

78

18

14

2,0

94

96

LR1+60

25 x 2.5

28/38

10

38

M8x25

25

105

65

35

90

20

15

2,5

107,5

111

LR1+70

35 x 4.0

38/45

12

45

M8x30

25

123

80

45

114

24

18

3,0

135

126

LR1+90

40 x 4.0

A

LR1

Coupling configurator

Coupling code

Item

LZR1

Type

Execution

Bore diameter

GESP

-

-

GESF

-

F…

GESM

F-C

F…

Hub 1

GESF38/45F35

GESA

-

F…

Spider 1

AES

B-G-R-V

-

Spider 2

AES

B-G-R-V

-

GESP

-

-

GESL38/45

AES38/45V

Length LR1

LR1= 1200 mm

AES38/45V

GESF

-

F…

GESM

F-C

F…

GESA

-

F…

Hub 2

56

GESF38/45F35

MS

Screw tightening torque

Nm

MT

Transmissible torque moment

Nm

Direct Drives

Order example

On request

15

dr

4

E

14

d

dminH

[mm]

Screws

Din912-8.8

H

M·L

www.sitspa.com

“GES LR3” execution with intermediate shaft

Ideal execution for long distance shaft connections. Torque

transmission is zero backlash. It is used in applications such as

automatic machines, lifting machines, palletizing machines, and

handling machines. Designed for length up to 4 m without

t

H

L

M

A

Ø dR

ØE

Ø dm a x

I

Sez A -A

ØD

e

t

Lw

MS [Nm]

4762-8.8

19

8

20

M6

10 e

24

10

28

M6

28

14

38

M8

Hub 1

J1

ØD

Hub 2 Shaft

J2

J3

Sez A -A

Lw

E

H

I

L

M

Lw Lw min Lzw

D

t

e

dR

[mm] [mm] [mm] [mm] [mm] [mm] A [mm] [mm] [mm] [mm] [mm] [mm]

CT

[Nm/rad]

Lzw

t

H

M

25

A 40

0,02002

0,01304

0,340

3003

10

0,07625

0,04481

0,0697

6139

25

0,17629

0,1095

1,243

10936

65

0,2572

3,072

27114

80 e

55

30

L

17,5

22

3

49

16

59

18

35

25 Sez 67

A -A

20

45

33

83,5

24

26

ØD

18

45

M8

25

42

22

50

M10

49

1,12166

0,5523

4,719

41591

95

50

36,5

93

86

1,87044

1,1834

9,591

84384

105

56

39,5

103

22

55

M12

ØE

Ø dR

Ø dm a x

38

0,50385

48

Ø dR

I

Torsional

rigidity

2

t

H

98

1

113

Lw+35

47

8

14,5

40

Lw+44

57

10,5

20

50

131

Lw+50L z w73

11,5

25

60

Lw+66

84

15,5

30

Lw+73

94

18

32

80

36

100

M

A 163

180

I

202

28

3

2

Lw+79 105 18,5

L

1

70

Ø dR

dmin dmax

[mm] [mm]

Screws

DIN

L

A

Length on

request

Size

of inertia

Moment

3

2

[10 kgm ]

with dmax hub 1

Clamping

ØE

Ø dm a x

Dimensions

finished

bores

Lzw

M

ØE

Ø dm a x

A

H

Lw

I

A

Lw

A

Coupling configurator

Coupling code

“AP”

Type

Execution

Bore diameter

GESP

-

-

GESF

-

F…

GESM

F-C

F…

GESA

-

F…

AES

B-G-R-V

-

Hub 1

GESM38/45F35

Spider 1

GESLR38/45

Order example

AES38/45V

Distanza tra gli alberi Lw

Spider 2

Lw= 1200 mm

AES

B-G-R-V

-

GESP

-

-

AES38/45V

GESF

-

F…

GESM

F-C

F…

GESA

-

F…

Hub 2

GESM38/45F35

MS

Screw tightening torque

J

Coupling moment of inertia

Nm

kgm2

CT

Torsional rigidity

Nm/rad

190107/ 2/ C L

Direct Drives

57

TRASCO® ES

e

Lzw

Sez A -A

ØD

bearing support (depending on rotation speed). The double slot

execution, allows spider mounting and replacement without

driver/driven machine displacement. All aluminum alloy for a very

low inertia.

30

π

nR =

JA + JL

JA ⋅ JL

CTdin

[min ]

−1

m=

JA

JL

nR =

30

π

JA + JL

JA ⋅ JL

CTdin

[min ]

−1

m=

JA

JL

www.sitspa.com

m=

+ J2

T = TK ⋅ S θ ⋅ SD = 10 ⋅ 1,2 ⋅ 4 = 48,0 [Nm]

JA KN

JL

TKN = TK ⋅ S θ ⋅ SD = 10 ⋅ 1,2 ⋅ 4 = 48,0 [Nm]

Bores and torques for friction with hub without keyway [Nm]

Size

TKN =∅48

0 10

Nm∅<11Tcal∅ 14

8 ,∅

∅ 15 ∅ 16 ∅ 18 ∅ 19 ∅ 20 ∅ 22 ∅ 24 ∅ 25 ∅ 28 ∅ 30 ∅ 32 ∅ 35 ∅ 38 ∅ 40 ∅ 42 ∅ 45 ∅ 46 ∅ 48 ∅ 50 ∅ 55

TKN = 48,0 Nm < Tcal

19

17

21

23

30

32

34

24

JA

JL

21

23

30

32

34

m=

28

JA = J1 + J2

54

58

TS = TAS ⋅

48

40

42

38

40

42

JL = J3 + J2

62

38

42

38

47

51

m = 1,5

53

59

J

JL

70

74

78

86

93

97

109m =

117 A 124

136JA 148

= J1

+ J2

70

74

78

86

93

97

109

117

124

136

148

156

163

136

149

155

174

186

198

1 217

235

248

260

199

217

226

⋅ SA =

T =T ⋅

253 S 271 AS290

m +317

1 344

1

1

⋅ S A = 22,0 ⋅

⋅ 1,5 = 13,2 [Nm]

m +1

1,5 + 1

m = 1,5

22362

,0 ⋅

m = 1,5

JL = J3 + J2

1

175

279

285

297

310

⋅ 1,5 =416

13,2 434

[Nm]452

1,380

5 + 1 407

498

T

,5 ⋅ 1,2 ⋅ 4couplings

= T ⋅ S data

⋅ S + Tfor

⋅ S intermediate

⋅ S = 13,2 ⋅ 1,6 ⋅ 1,2 + 12

= 85,34 [Nm] (GES LR1 - GES LR3)

Technical

shaft

T

= T ⋅ S ⋅ S + T ⋅ S ⋅ S = 13,2 ⋅ 1,6 ⋅ 1,2 + 12,5 ⋅ 1,2 ⋅ 4 = 85,34 [

K max

S

Z

θ

K

D

θ

K max

S

Z

K

θ

θ

D

,2 [Nm]

TK max = 85,34Misalignment

Nm < Tcal

14

1,0

TK max = 85,34 Nm < Tcal

Angular

∆Kw

[°]

∆kr

1,2 + 12,5 ⋅ 1,2 ⋅ 4 =

85,34Assial

[Nm]

∆Ka

[mm]

0,9

19/24

1,2

0,9

24/28

1,4

0,9

28/38

1,5

0,9

38/45

1,8

0,9

1

CTot =

2⋅

1

+

CT anello

(∆ Kw)

1

2⋅

L intermediate shaft

1

+

CT spider CT intermediate shaft

L intermediate shaft =

[Nm / rad]

L intermediate shaft =

L zw − 2 ⋅ L

[ mm]

1000

L zw − 2 ⋅ L

[ mm]

1000

Selection diagram GES LR3 coupling

5

/4

38 8

LR 8/3

ES 2

G LR 2

ES 4/3

G

2

LR 24

ES 9/

G R1

L

ES

G

3000

2500

2000

rpm [min-1]

1500

1000

500

1000

1500

2000

Lw [mm]

Direct Drives

[Nm / rad]

CT allunga

∆Kr = (L z − 2 ⋅ H − M) ⋅ tan (∆ Kw)

with Lzw = total coupling length

58

L allunga

Radial misalignment

Angular misalignment = 0,9° per spider

CTot =

∆kw

Size

2500

3000

3500

4000

[mm]

L allunga =

L zw − 2 ⋅

1000