s - The history of Ericsson

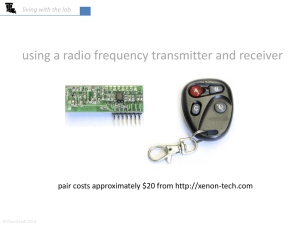

advertisement