chapter 4: fracture

advertisement

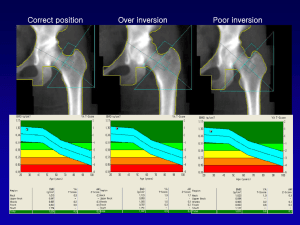

CHAPTER 4: FRACTURE The separation or fragmentation of a solid body into two or more parts, under the action of stresses, is called fracture. Fracture of a material by cracking can occur in many ways, principally the following: 1.Slow application of external loads. 2.Rapid application of external loads (impact). 3.Cyclic or repeated loading (fatigue). 4.Time-dependent deformation (creep). 5.Internal stresses, such as thermal stresses caused by anisotropy of the thermal expansion coefficient or temperature differences in a body. 6.Environmental effects (stress corrosion cracking, hydrogen embrittlement, liquid metal embrittlement, etc.) CHAPTER 4: FRACTURE The process of fracture can, in most cases, be subdivided into the following categories: 1. Damage accumulation. 2. Nucleation of one or more cracks or voids. 3. Growth of cracks or voids. (This may involve a coalescence of the cracks or voids.) CHAPTER 4: FRACTURE Theoretical fracture strength Early estimates of the theoretical fracture strength of a crystal were made by considering the stress required to separate two planes of atoms. Figure shows schematically how the stress might vary with separation. The attractive stress between two planes increases as they are separated, reaching a maximum that is the theoretical strength, σt, and then decaying to zero. The first part of the curve can be approximated by a sine wave of half wavelength x* , CHAPTER 4: FRACTURE CHAPTER 4: FRACTURE CHAPTER 4: FRACTURE Stress concentration The reason that the theoretical predictions are high is that they ignore flaws, and all materials contain flaws. In the presence of a flaw, an externally applied stress is not uniformly distributed within the material. Discontinuities such as internal cracks and notches are stress concentrators. For example, the stress at the tip of the crack, σ max, in a plate containing an elliptical crack (Figure 14.2)is given by CHAPTER 4: FRACTURE CHAPTER 4: FRACTURE Griffith reasoned that a preexisting crack could propagate under stress only if the release of elastic energy exceeded the work required to form the new fracture surfaces. However, his theory, based on energy release, predicted fracture strengths that were much lower than those measured experimentally. Orowan realized that plastic work should be included in the term for the energy required to form a new fracture surface. With this correction, experiment and theory were finally brought into agreement. Irwin offered a new and entirely equivalent approach by concentrating on the stress states around the tip of a crack. CHAPTER 4: FRACTURE Griffith theory Griffith approached the subject of fracture by assuming that materials always have preexisting cracks. He considered a large plate with a central crack under a remote stress, σ ,and calculated the change of energy, U ,with crack size (Figure 14.3). There are two terms: One is the surface energy associated with the crack, CHAPTER 4: FRACTURE CHAPTER 4: FRACTURE Orowan theory Gc is the strain energy release rate CHAPTER 4: FRACTURE Fracture modes There are three different modes of fracture, each having a different value of Gc. These modes are designated I, II, and III, as illustrated in Figure 14.4.In mode I fracture, the fracture plane is perpendicular to the normal force. This is what is occurs in tension tests of brittle materials. Mode II fractures occur under the action of a shear stress, with the fracture propagating in the direction of shear. An example is the punching of a hole. Mode III fractures are also shear separations, but here the fracture propagates perpendicular to the direction of shear. An example is the cutting of paper with scissors. CHAPTER 4: FRACTURE Irwin ’s fracture analysis Irwin noted that in a body under tension, the stress state around an infinitely sharp crack in a semi-infinite elastic solid is entirely described by * CHAPTER 4: FRACTURE CHAPTER 4: FRACTURE CHAPTER 4: FRACTURE CHAPTER 4: FRACTURE Plastic zone size 14.8 CHAPTER 4: FRACTURE