State transition diagram

ENMA 6010

State Transition Diagrams

Modeling Time-Dependent Behavior

© 2010 Mark Polczynski

All rights reserved

Reference: Wikipedia – State Transition Diagrams

ENMA 6010: State Transition Diagrams 1

Characteristics of Good Models

1.

Graphical, with support for detailed text descriptions: Picture is worth a thousand words picture links to a thousand words.

2.

Top-down partitionable: Globe Continents Countries

3.

Minimally redundant: Make changes in just one place in the model.

4.

Transparent: Requires no expertise in model building to understand the model.

ENMA 6010: State Transition Diagrams 2

Goals of System Modeling:

1.

To focus on important system features while downplaying less important features,

2.

To discuss changes and corrections to the user’s requirements at low cost and with minimal risk,

3.

To verify that we understand the user’s environment,

4.

To verify that we have documented our understanding in a way that would allow others to construct/maintain the system.

ENMA 6010: State Transition Diagrams 3

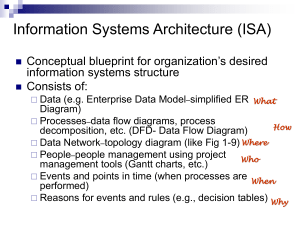

We will be studying four related modeling approaches:

• Data flow diagram – system function

• State transition diagrams – time dependent behavior

• Entity relationship diagram – stored data/material

• Process flow diagrams – actions and decisions

How does this fit?

ENMA 6010: State Transition Diagrams 4

Process flow diagram

Control flow

Control function

State transition diagram

Entity relationship diagram

ENMA 6010: State Transition Diagrams 5

Control Function

• The control function coordinates the activities of the other DFD functions.

• Control function inputs and outputs are 1-bit on/off yes/no signals.

• No data/materials flowing on control lines!

• These signals “wake up” other DFD functions when the function needs to transform inputs to outputs.

• These could be expected or unexpected conditions.

• Typically there is only one control function for a particular data flow diagram.

ENMA 6010: State Transition Diagrams 6

STD vs. DFD

• The state transition diagram goes inside the control function.

• The control function inputs and outputs connect to the state transition diagram.

• The STD defines how the DFD functions (bubbles) get turned on and off.

• Thus, the state transition diagram controls system sequencing and timing.

Let’s see how this works…

ENMA 6010: State Transition Diagrams 7

State Transition Diagrams

State:

Some behavior of a system that is observable and that lasts for some period of time .

A state is when a system is:

• Doing something – e.g., heat ing oven, mix ing ingredients, accelerat ing engine,

• Waiting for something to happen – Wait ing for user to enter password, wait ing for sensor reading.

Transition:

(Virtually) instantaneous change in state (behavior).

ENMA 6010: State Transition Diagrams 8

Here’s a simple example STD for a washing machine.

State

Transition

Condition

Action

ENMA 6010: State Transition Diagrams 9

A condition is typically some kind of event , e.g.:

• Signal

• Arrival of an object (data/material),

• Etc…

An action is the appropriate output or response to the event, e.g.:

• Signal or message

• Transfer of an object,

• Calculation,

• Etc…

Condition

Action

ENMA 6010: State Transition Diagrams 10

Here’s a simplified data flow diagram for our wash machine, which shows the three primary functions and associated material flows:

State transition diagram

How does this relate to our state transition diagram?

ENMA 6010: State Transition Diagrams 11

Control lines in DFD are associated with conditions and actions in STD

1-bit on/off signals

Timer

ENMA 6010: State Transition Diagrams 12

Similarly…

• The DFD shows flow of entities for Make Lunch

• The STD shows timing for Make Lunch

ENMA 6010: State Transition Diagrams 13

This is pretty boring, isn’t it?

Couldn’t we just write this down as a sequence of text statements?

Start

Do until wash cycle complete

Wash clothes

Do until rinse cycle complete

Rinse cloths

Do until spin cycle complete

Spin-dry clothes

End

ENMA 6010: State Transition Diagrams 14

Here’s a more interesting (simplified) diagram which shows exception handling.

Text descriptions start getting messy when you have to account for every possible if-then-else exception to normal operation.

ENMA 6010: State Transition Diagrams 15

Here’s an even more interesting example.

It is now perfectly clear that you:

• Can go right to rinsing without washing, but..

• Can never go to spin-drying without rinsing.

So, what would I use such a modeling technique for?

ENMA 6010: State Transition Diagrams 16

State Transition Diagram vs. DFD Context Diagram

For DFDs , we used the context diagram to show how the system interacts with the external world (terminators).

For STDs, a condition can be an event occurring in the environment external to the system being modeled,

And actions can be responses sent back to the external environment.

Condition X =

External event at terminator

Action Y =

Response to terminator

External

Terminator

State

Object 1

Condition X

Action Y

Object 2

Context

Diagram

ENMA 6010: State Transition Diagrams 17

State Transition Diagram Use

• State transition diagrams have bee used for a long time to model real-time systems such as:

• Process control,

• Telephone switching systems,

• Data acquisition systems,

• Military command and control systems.

• They are also quite useful in modeling “object oriented systems” such as those produced by Visual Basic.

• These are software program that basically sit there waiting until you initiate an event such as clicking an icon or hitting the “Enter” key.

ENMA 6010: State Transition Diagrams 18

PowerPoint waiting for user to select function

Several possible state transitions

Condition: Select “File”

Action: Open File dialog box

PPT waiting for “File” function selection

Several possible state transitions

ENMA 6010: State Transition Diagrams 19

Building State Transition Models

The literature and the references for this course provide details on rules and processes for building good state transition models.

We will not cover these details here, but we will touch on some key points in the following slides…

ENMA 6010: State Transition Diagrams 20

A transition arrow without an originating state is the system’s start state

A system is not required to have a specified start state, but most do.

For example, does your computer always start in a pre-defined state when power is applied?

Or does it power up running PPT some days, and Outlook others?

ENMA 6010: State Transition Diagrams 21

A state with no transition arrows out is the system’s end state

A system can have multiple end states

ENMA 6010: State Transition Diagrams

But…

22

Systems typically do not have end states.

The end state is essentially “ dead ”, since you can’t ever get back to any other state.

Except if you are a cruise missile…

ENMA 6010: State Transition Diagrams 23

Guards

So far, we have seen the use of states, transitions, events, and actions.

A guard is a True/False statement that enables a transition to occur.

In this example of editing a

PowerPoint presentation… no object in the ppt slide has been selected… so the Cut, Copy, and Clear functions are disabled .

This is because a guard has detected that “object selected” is

“false”, so transitions to these states are not allowed.

ENMA 6010: State Transition Diagrams 24

Thug insults Dirty Harry

“Make my day!”

Waiting for trigger pulled

Guard

Trigger pulled & safety on

Bullet fired disabled

Trigger pulled & safety off

Bullet fired

Captain arrives

Gun holstered

ENMA 6010: State Transition Diagrams

Common example of the use of a state transition guard

25

Returning to our simplified washing machine…

Rinse signal

Start rinse cycle

Timer

Idle

Wash signal

Star wash cycle

Washing

Guard

Wash cycle complete

Start rinse cycle

Rinsing

Spin-dry cycle

Complete

Sound buzzer

Door open

Disable spin-dry cycle

Rinse cycle complete

Start spin-dry cycle

Can’t start the spin cycle while the door is open.

Spin-drying

ENMA 6010: State Transition Diagrams 26

Top-Down Partitionable Modeling

• Recall that STDs are inside of the control functions on DFDs.

• Now, DFDs can be decomposed into levels, and STDs follow the DFDs, so STDs are naturally decomposable.

Furthermore!

Sometimes it can help clarify things if you decompose an STD within a DFD…

ENMA 6010: State Transition Diagrams 27

Top-Down Modeling:

Just as for functions in data flow diagrams, states can be broken into sub-states.

ENMA 6010: State Transition Diagrams 28

STD Logical Models vs. Physical Models

• For data flow diagrams, we distinguished between logical models and physical models (essential vs. environmental models).

• For DFDs, the major difference is usually the appearance of

“implementation stores” which buffer objects (data/materials).

• We use these to store objects while we are “waiting for” something to happen.

• A similar situation holds for STDs.

Waiting for lunch

ENMA 6010: State Transition Diagrams 29

Logical Models vs. Physical Models

• In the logical/essential world, state transitions are virtually instantaneous .

• But in the real world, transitions may actually take some time, just like DFD functions take time.

• This may cause “Waiting for transition to complete” states to be added to the physical/environmental model used used for actual system implementation.

• This is just like adding implementation stores to DFDs.

ENMA 6010: State Transition Diagrams 30

PowerPoint waiting for user to select function

Several possible state transitions

PPT waiting for “File” function selection

Several possible state transitions

Here’s another difference between logical and physical models–

Logical model condition:

Select “File”

Implementation independent

Physical model condition:

Left click on “File”

Or keyboard Alt-F

Implementation dependent

ENMA 6010: State Transition Diagrams 31

Building a State Transition Diagram

Here is one approach:

1.

Identify an initial state and walk through the sequence of states.

2.

Look for all possible state transitions (branches) as each state is identified.

For the second approach, states can be identified through a systematic process:

1. List all of the conditions that the system takes,

2. Identify all of the actions that result from each condition.

3. Identify the state that follows each condition/action pair: what is the system waiting for after the action takes place?

4. Look for additional condition/action pairs not initially identified.

ENMA 6010: State Transition Diagrams 32

Building a State Transition Diagram

For the second approach, you have a bunch of condition/action/state “genes”.

Now, you need to link all of the genes together into a chromosome:

For each state, what condition(s)/event(s) is the system waiting for?

What chromosome(s) provide the event?

State X

Condition X

Action X

“Gene”

Add link when you find Action X which produced Condition Y.

State Y

Condition Y

Action Y

ENMA 6010: State Transition Diagrams 33

Building a State Transition Diagram

This process works pretty well for having at team jointly converge to a state transition diagram.

Here, individuals write individual condition/action/state chromosomes on postit notes.

Then, the team compares individual chromosomes, modifying, combining and eliminating as needed.

Chromosomes can then be assembled into a diagram. Do this by randomly selecting one chromosome, and then finding the chromosomes with the conditions that the chromosome state is waiting for.

Repeat this for al the chromosomes you just added to the diagram, and iterate until all the chromosomes are used up.

It can be tempting for individuals to assemble their chromosomes into diagrams before comparing with the team, but the team should reach consensus on chromosomes before assembling the diagram.

ENMA 6010: State Transition Diagrams 34

Building a State Transition Diagram

After you have constructed the diagram, check the following:

1. Do you have a start and one or more end states (if needed)?

2. Can you transition into all states except the start state?

3. Can you exit all states except end states?

4. Are there any other conditions not covered?

5. Are there any other actions not covered?

If possible, check your diagram by doing a live process walk-through.

ENMA 6010: State Transition Diagrams 35

Enter

Identify

States

List all events that occur in the system

For each event, identify the corresponding action

Build

Diagram

Compare all eventaction-state sets

Link states with actions

For each event-action pair, identify a unique

“following” state

Eliminate duplicate states

Put the event-actionstate sets on selfstick notes

Identify missing states

Test

Model

Walk through system operation using the model

Review and Revise

Exit

Process Flow Diagram for

State Transition

Diagramming

No

Model accurate?

Yes

Use the model

ENMA 6010: State Transition Diagrams 36

State Transition Matrix

As with DFDs and ERDs, things can get pretty messy.

Plus, it’s nice to have a systematic way to check for consistency,

And also to identify the myriad exception/unexpected situations.

From The state transition matrix can help.

To

State 1

State 2

State 3 etc…

Condition

Action

Condition

Action

ENMA 6010: State Transition Diagrams 37

1. Primary State Transitions

From

Do this first to define desired operation.

Check blank cells – have we covered all possible desired transitions?

To

Idle

Wash signal

Washing

Start wash cycle

Rinsing

Rinse signal Wash cycle complete

Start rinse cycle Start rinse cycle

Spin-

Drying

Rinse cycle complete

Start Spin-dry cycle

ENMA 6010: State Transition Diagrams

Spin-dry cycle complete

Sound buzzer

38

Rinse signal

Start rinse cycle

Idle

Wash signal

Star wash cycle

Washing

Wash cycle complete

Start rinse cycle

Rinsing

Spin-dry cycle

Complete

Sound buzzer

Door open

Disable spin-dry cycle

Rinse cycle complete

Start spin-dry cycle

Spin-drying

To

Idle

Do this next to incorporate guards.

Washing

Rinsing

Spin-

Drying

From

2. Guards

ENMA 6010: State Transition Diagrams

Door open

Disable spin-dry cycle

39

Idle

Start signal

Star wash cycle

Stop signal

Stop washing

Washing

Wash cycle complete

Start rinse cycle

Stop signal

Stop rinsing

Rinsing

Stop signal

Stop spin-drying

Rinse cycle complete

Start spin-dry cycle

Spin-drying

Spin-dry cycle

Complete

Sound buzzer

To

Idle

Finally, do this to cover all the possible exceptions to the normal operating sequence.

Washing

Rinsing

Spin-

Drying

From

3. Exceptions

Stop signal Stop signal Stop signal

Stop wash cycle Stip rinse cycle Stop spin-dry cycle

ENMA 6010: State Transition Diagrams 40

State Transition Diagram Example

Here is part of a STD for a calculator, highlighting the function of the

Clear and Off buttons, using UML (unified modeling language) notation

(see: http://en.wikipedia.org/wiki/UML_state_machine).

Start

ENMA 6010: State Transition Diagrams

End

41

State Transition Diagram Example

Here is an interesting example of a state transition diagram:

““The Emotional State-Transition Diagram” http://syque.com/articles/state-transition/state-transition.htm

The first diagram shows what happens when a customer calls in to a call center with a problem…

ENMA 6010: State Transition Diagrams 42

Note: This is an “expected” sequence. The “unexpected” events and transitions have not been considered, e.g., customer dials wrong number.

Call center system

STD

ENMA 6010: State Transition Diagrams 43

Customer

STD

This describes the states that the customer is in vs. the call center system states.

ENMA 6010: State Transition Diagrams 44

Customer’s emotional state

STD

ENMA 6010: State Transition Diagrams 45

Finally:

As mentioned, a state is when a system is:

• Doing something - Heating oven, mixing ingredients, accelerating engine,

• Waiting for something to happen – Waiting for user to enter password, waiting for sensor reading.

Well, waiting for something to happen is just a waste of time,

So state transition diagrams can be helpful in identifying and minimizing or eliminating time-wasting states .

Just like data flow diagrams were useful in identifying and minimizing or eliminating inventory and work-in-process .

You can do this by comparing logical/essential models with physical/environmental implementation models.

Do you really need to wait for some thing to happen?

ENMA 6010: State Transition Diagrams 46

Characteristics of Good Models

1.

Graphical, with support for detailed text descriptions: Picture is worth a thousand words picture links to a thousand words.

2.

Top-down partitionable: Globe Continents Countries

3.

Minimally redundant: Make changes in just one place in the model.

4.

Transparent: Requires no expertise in model building to understand the model.

ENMA 6010: State Transition Diagrams 47

Goals of System Modeling:

1.

To focus on important system features while downplaying less important features,

2.

To discuss changes and corrections to the user’s requirements at low cost and with minimal risk,

3.

To verify that we understand the user’s environment,

4.

To verify that we have documented our understanding in a way that would allow others to construct/maintain the system.

What’s next?

ENMA 6010: State Transition Diagrams 48

We will be studying five modeling approaches:

• Data flow diagram – system function

• State transition diagrams – time dependent behavior

• Entity relationship diagram – stored data/material

• Process flow diagrams – actions and decisions

How does this fit?

ENMA 6010: State Transition Diagrams 49

Process flow diagram

Control flow

Control function

State transition diagram

Entity relationship diagram

ENMA 6010: State Transition Diagrams 50