Boiler Operation

advertisement

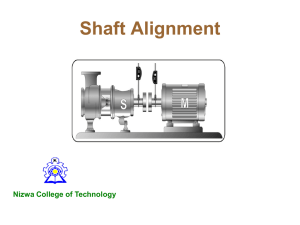

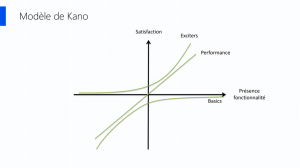

INSTRUCTOR: ROBERT A. MCLAUGHLIN ZAILI THEO ZHAO 1 MACHINERY ALIGNMENT & VIBRATION ANALYSIS 19:15 POWER EQUIPMENT LEARNING OBJECTIVES Understanding of the importance of accurate alignment and benefits of vibration analysis on rotating equipment Identify the factors that must be considered prior to any alignment job. Identify the tools necessary for proper alignment. Examine various power transmission couplings and determine their applications and limitations. Identify the types of misalignment found in rotating machinery. Identify allowable misalignment tolerance associated with good alignment practices. Examine the dial indicator method of alignment and explain the “validity rule” and “repeatability”. 19:15 2 COUPLINGS Couplings connect two shafts, end-to-end in the same line, for two main purposes. Transmit power (torque) from one shaft to the other, causing both to rotate in unison, at the same RPM. Compensate for minor amounts of misalignment. Are also sacrificial elements in some cases, and are much less expensive to replace than a crank shaft or rotor assembly. 19:15 3 COUPLINGS - TWO TYPE OF COUPLINGS Solid couplings 19:15 Solid coupling have no tolerance for misalignment, strictly for transmitting torque. Torque is transmitted by the friction between the faces of the couplings Coupling bolts are torqued to 40,000 lb/in2 – this elongates the bolt 1 ½ mils. The proper bolt torque is necessary to create the necessary face friction. No lubrication is required 4 COUPLINGS - TWO TYPE OF COUPLINGS Flexible couplings Allow for flexible, random movement axial movement, thermal expansion, and slight misalignment between two shafts. Flexible couplings are classified as Mechanical-Flexing has components that move or slide in relation to each other to accommodate shaft misalignment. Mechanical flexing couplings require lubrication. 19:15 5 COUPLINGS - TWO TYPE OF COUPLINGS Flexible couplings Types include: Chain, gear, grid and pin type couplings gear 19:15 grid disc Chain pin 6 COUPLINGS Diaphragm Material Flexing uses a flexible material between the coupling halves to accommodate misalignment. Common materials include metal, rubber, plastic, or composite material. Material flexing couplings do not require lubrication. Types include: Spring Diaphragm flexible disc-ring Elastomer Spring Elastomer 19:15 disc 7 ELASTOMER COUPLING 19:15 8 FUNCTIONS OF COUPLING Connect/ disconnect driver to driven component. Allow slight misalignment only flexing type. Absorb shake - sacrificial element. Torque transmission. Absorb vibration. 19:15 9 WHY ALIGNMENT IS IMPORTANT Proper alignment between the driver and the driven equipment serves to: Reduce noise 19:15 Misaligned equipment creates noise as it is running. Vibration reduction Prolong equipment life Misalignment and vibration decreases bearing life It also reduces coupling life Reduces costs It takes more power to drive misaligned equipment. it can increase energy cost by up to 12% 10 POOR ALIGNMENT Poor Alignment means: Premature bearing, seal, shaft and coupling failures High Bearing and coupling temperatures Excessive vibration Looseness of foundation bolts. The breaking (or cracking) of shafts at, or close to the inboard High power consumption 19:15 11 FACTORS TO CONSIDER PRIOR DOING ALIGNMENT: Consider the two components – which is easier to move 19:15 Driver – Motors, turbines, etc. Driven – Pumps, generators, etc. Jacking bolts may be welded to the foundations to assist with the movement of the equipment. 12 FACTORS TO CONSIDER PRIOR DOING ALIGNMENT: Stress Elimination – Piping must not create any stress on the equipment. 19:15 To test, disconnect pump suction and discharge piping. If the piping springs away from the pump when disconnected, stress exists and can cause misalignment when reconnected. 13 FACTORS Soft Foot – A condition that occurs when one or more machinery feet do not make complete contact with the base. Soft foot can exist when the mounting plate is uneven from rust or the plate is warped, or the machinery foot is warped or rusted, or both. To correct, clean all surfaces, fasten the equipment solidly with three mounting bolts, and then use a feeler gauge to measure under the fourth foot. To level the equipment, you must put shims equal to the feeler gauge thickness under this foot, or alternatively, you can put an amount of shims equal to half the feeler gauge thickness under the measured foot, and half under the foot that is diagonally opposite the measured foot. 19:15 14 FACTORS Coupling Speed – Must be known to determine the allowable tolerance. 19:15 As the speed of the machinery increases, the acceptable misalignment decreases Shaft thrust – you need to know if either of the rotating components has thrust in order to maintain the proper air gap Air gap - the space between the face of the couplings. 15 FACTORS Run out Before couplings can be aligned, you must check both shafts and couplings for run out. 19:15 Shaft and coupling run out means that the motor or pump shaft and coupling hub centerlines do not lineup properly or the shaft and coupling centerlines are non-colinear. Shaft and coupling run out exceeding .003˝ must be corrected before couplings can be aligned. 16 FACTORS TO CONSIDER PRIOR DOING ALIGNMENT: Run out condition can be caused by: Bent shafts Bad coupling bores- angular or parallel offset bores Damaged coupling hubs or egg shaped hubs 19:15 Note: Bad bearings may look like run out but are simply bad bearing and will also need replacement prior to doing an alignment job. 17 Feeler TOOLS OF ALIGNMENT Tools of alignment include anything that will measure accurately to .001” or 1 mil. Dial Indicators Feeler gauges Taper gauges Taper Straight edge Dial Indicators Optical scopes Lasar units 19:15 18 THREE TYPES OF MISALIGNMENT: Parallel – the shafts are parallel but the centerlines are offset, either vertically or horizontal. Angular – the faces are uneven but the centerlines intersect. Combination of parallel and angular – this is the most common situation that must be corrected. 19:15 19 TYPES OF MISALIGNMENT Place a straight edge firmly against the rim of one coupling half Use feeler gauges to determine the gap between the straight edge and the other coupling half rim. 19:15 To correct parallel misalignment, you use what is known as the rim method. The rim method consists of using the outer rim of the coupling to correct the misalignment. Three ways of accomplishing: Straight edge and feeler gauges – a straight edge can be use to for rough alignment, then an indicator or laser can be used to complete the alignment process. 20 TYPES OF MISALIGNMENT Dial indicator Clamp the dial indicator base to the shaft of the equipment that will not be moved. Use dial indicator extension arms to allow the indicator to measure the amount of misalignment. Be aware that if extension arms are two long they can sag, which can lead to inaccurate readings. Set the indicator at 0 in the 12 o’clock position. Take reading at the 3, 6, and 9 o’clock positions. For top to bottom parallel misalignment, determine how many thousands the shafts are out of alignment. The actual offset is equal to ½ the sum of the indicator readings. Same thing is done for up and down parallel misalignment. 19:15 21 TYPES OF MISALIGNMENT Lasers – very accurate alignment tool. 19:15 22 TYPES OF MISALIGNMENT Validity Rule You should always rotate the indicator a full 360o of rotation when taking readings. In some installations this may be difficult to achieve. The validity rule states that the sum of the right side readings plus the left side readings should equal the bottom reading (+-10%). (left) + (right) = bottom + 0 (top) This is to check the accuracy of your indicator setup and to also insure there is no excessive shaft or coupling run out. 19:15 23 TYPES OF MISALIGNMENT To correct angular misalignment- 19:15 If the air gap is big enough, the dial indicators can be use as shown. If not, feeler gauges can be used between the faces. With either method, the readings and correction are taken like the ones for parallel misalignment. --- use Face--24 TYPES OF MISALIGNMENT Repeatability It is when you set up the dial indicator to take reading at the 12 o’clock, 3 o’clock, 6 o’clock & 9 o’clock positions and you want to insure the accuracy of your setup by rotating the indicator around and repeating the zero reading on the dial indicator at the top of the coupling. There is no point in trying to do the alignment process if you have not eliminated soft foot or if you cannot repeat zero at the top of the coupling. To correct parallel misalignment--- use Rim --- 19:15 25 FIVE STEPS TO PROPER ALIGNMENT 2) 3) 4) 5) Check and correct for coupling ‘run out’. Check and correct for soft foot. Check and fix angular. Check and fix parallel vertically Check and fix parallel horizontal 19:15 1) 26 SUGGESTED ANGULAR ALIGNMENT GUIDE Excellent mils per inch Acceptable mils per inch 600 1.5 2.5 900 1. 1.5 1200 .7 1.0 1800 .5 .7 3600 .3 .5 19:15 RPM 1 mil = .001 in Consult machinery manufacturer 27 19:15 28 THREE THINGS YOU NEED TO KNOW When aligning rotating machinery there are 3 things you need to know 19:15 Where is the machinery at when the equipment is not running? What position will the machinery move to when operating? If the machinery moves from off-line to running conditions, what acceptable range of positions could the machinery shafts be in when the machinery is aligned off-line and still maintain acceptable alignment tolerance during operation? Or simply… Where are they? Where will they go? Where should they be? 29 ALIGNMENT TOOL 19:15 30 IMPORTANT 19:15 Proper alignment takes time and patience to accomplish but the results will be worth the effort. Equipment will run quieter with less vibration and operating budgets will be reduced. Equipment life expectancy can be significantly increased and energy consumption can show a significant decrease. 31 19:15 THANK YOU 32