Wool Processing

advertisement

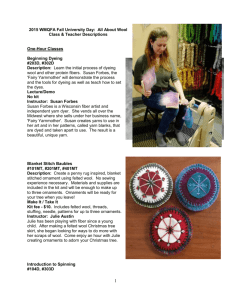

Wool Processing Spinning with Clean Wool A. Wash Fleece Lithograph ca 1850. Two theories There are two different ways to clean wool. 1) Clean the wool before you card and spin. 2) Clean the yarn after you spin. This is called spinning in the grease. Sheering Sheep B. Sort Wool ONE METHOD OF WOOL SORTING 1—The Best Grade; 2—Lowest Grade; 3—Fair; 4—Medium Grade. Wool hair strand under microscope • CROSS SECTION OF A WOOL FIBER THE MEDULLA IS FOUND ONLY IN COURSE WOOL. • SINGLE WOOL FIBER SHOWING ITS NATURAL CRIMP WHICH GIVES WOOL ITS WONDERFUL RESILIENCE. C. Card Wool • Fibers are combed in the same direction to form rolog for spinning. • Produced woolen fibers to spin. rolog Machine Carding • Commercial Carding machines and the end product is worsted fibers. • WOOLEN YARN IS SPUN AFTER CARDING • WORSTED YARN IS NOT ONLY CARDED BUT IS GIVEN EXTRA COMBING TO REMOVE SHORTER FIBERS D. Comb Wool wool card • Just like carding; however the teeth are longer and thicker and not as fine. E. Spin Wool • 'S' and 'Z' TWISTS SHOW DIRECTION YARN IS SPUN • THE AMOUNT OF TWIST IN YARN DETERMINES THE STRENGTH. NO TWIST SHOWS THE FIBERS PARALLEL; THIS IS VERY SOFT WEAK YARN. WITH MORE TWIST IN THE YARN, IT BECOMES STRONGER AND HARDER F. Ply Yarn Ply: Refers to the number of single spun yarn elements twisted together to form a heavier and stronger yarn, called a plied yarn. (see diagram)