Shunt Motors

advertisement

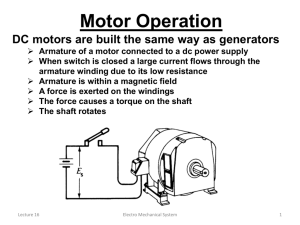

DC Motors • Construction very similar to a DC generator • The dc machine can operate bath as a generator and a motor. • When the dc machine operates as a motor, the input to the machine is electrical power and the output is mechanical power. • In fact, the dc machine is used more as a motor. • DC motors can provide a wide range of accurate speed and torque control. • Principle of operation – when a current-carrying conductor is placed in magnetic field, it experiences a mechanical force., F = Bli Eg. Gas turbine, diesel engine, electrical motor DC Motors • Separately Excited Motors Field and armature windings are either connected separately. •Shunt Motors Field and armature windings are connected in parallel. • Series Motors Field and armature windings are connected in series. • Compound Motors Has both shunt and series field so it combines features of series and shunt motors. Comparisons of DC Motors Shunt Motors: “Constant speed” motor (speed regulation is very good). Adjustable speed, medium starting torque. Applications: centrifugal pump, machine tools, blowers fans, reciprocating pumps, etc. Series Motors: Variable speed motor which changes speed drastically from one load condition to another. It has a high starting torque. Applications: hoists, electric trains, conveyors, elevators, electric cars. Compound motors: Variable speed motors. It has a high starting torque and the no-load speed is controllable unlike in series motors. Applications: Rolling mills, sudden temporary loads, heavy machine tools, punches, etc Shunt Motor • The armature circuit and the shunt field circuit are connected across a dc source of fixed voltage Vt Rfc in the field circuit is used to control the motor speed by varying if. = If(Rfc + Rfw) Power Flow and Efficiency SHORT SHUNT COMPOUND MOTOR • depend on machine size • Range shown for machine 1 to 100 kW Power Flow and Losses in DC Motors Protational VtIt VaIt VaIa EaIa Pout Pinput It 2Rsr It 2Rt Ia 2Ra – T characteristics Speed- torque characteristics of DC motors Example 11 Q. A DC machine (12 kW, 100 V, 1000 rpm) is connected to a 100 V DC supply and is operated as a DC shunt motor. At no-load condition, the motor runs at 1000 rpm and the armature current takes 6 A. Given armature resistance Ra= 0.1 , shunt field winding resistance Rfw= 80 , and Nf= 1200 turns per pole. The magnetization characteristic at 1000 rpm is shown in the next figure. Find the value of shunt field control Rfc Find the rotational losses at 1000 rpm Find the speed, torque, and efficiency when the rated current flows. a. b. c. i) ii) Consider the air gap flux remains the same ( no armature reaction) at that at no load Consider the air gap flux reduces by 5 % when the rated current flow in the armature due to the armature reaction d. Find the starting torque is the starting current is limited to 150 % of its rated current i) Neglect armature reaction ii) Consider armature reaction, IfAR = 0.16A Sen pg. 170 Sol_pg8 Cont. Example 99.4 0.99 Separately Excited DC Motor – Torque speed characteristic AR- Improve speed regulation Vt and flux constant - Drop in speed as torque increase is small – good speed regulation DC Speed Control • Can be achieved by • Armature Voltage Control, Vt • Field resistance control, • Armature resistance Control, Ra • Speed increases as Vt increases, Ra increases and field flux decreases Torque Torque TL = Cm2 TL = K Low speed hoist, elevator Fans, blowers, centrifugal pumps Speed Load Torque profile Speed Armature Voltage Control m m T=1 No load speed Vt increasing Vt1 T=0 T=2 Full load speed Vt2 Vt3 Vt4 Armature Voltage control- T Armature Voltage control- Constant load torque – speed varies linearly as Vt changes Terminal voltage (Vt) variesspeed adjusted by varying Vt Vt The speed of DC motor can simply be set by applying the correct voltage ( fixed flux and Ra). Good speed regulation. Maintain maximum torque capability. Expensive control. Field Control m Flux decreasing Rfc max if1 Vt (R a R ae ) ω T 2 KaΦ (Ka Φ) if2 if3 Rfc=0 where i f if4 T Field Control The speed of DC motor can simply be set by applying the correct field resistance (Rfext) ( fixed Va and Ra). Slow/sluggish transient respond. Unable to maintain maximum torque capability. Simple and cheap control. Armature Resistance Control m Ra increasing Rae=0 No load speed Vt (R a R ae ) ω T 2 KaΦ (Ka Φ) Raemax Resistance control TL rated T The speed of DC motor can simply be set by applying the correct armature resistance (Raext) ( fixed Va and Rf). Poor speed regulation. High Losses. Unable to maintain maximum torque capability ( TL rated). Simple and cheap control. Example 12 • A variable speed drive system uses a dc motor which is supplied from a variable-voltage source. The drive speed is varied from 0 to 1500 rpm (base speed) by varying the terminal voltage from 0 to 500 V with the field current maintained constant. (a) Determine the motor armature current if the torque is held constant at 300 N-m up to the base speed. (b) Determine the torque available a speed of 3000 rpm if the armature current is held constant at the value obtained in part (a). Neglect all losses. Sen pg 180 Sol_pg15_motor Series Motor T – characteristics Speed- torque characteristics of DC motors Example 13 • A 220 V, 7 hp series motor is mechanically coupled to a fan and draws 25 amps and runs at 300 rpm when connected to a 220 V supply with no external resistance connected to the armature circuit (Rae= 0 ). The torque required by the fan is proportional to the square of the speed. Ra= 0.6 and Rsr= 0.4 . Neglect armature reaction and rotational loss. (a) Determine the power delivered to the fan and the torque developed by the machine. (b) The speed is to be reduced to 200 rpm by inserting a resistance Rae in the armature circuit. Determine the value of this resistance and the power delivered to the fan. PC Sen pg 182 Sol_pg18 Motor Starter • If a DC motor directly connected to a DC supply, the starting current will be dangerously high Vt E a Ia Ra Ea K a 0 at start;I a Vt Ra •Ra small, Ia large. Ia can be limited to a safe value by: •Insert an external resistance, Rae •Use a low dc voltage (Vt) at starts, which require a variable-voltage supply •With external resistance, Vt E a Ia R a R ae Motor Starter Ea speed (). As speed increases Rae can be gradually taken out without the current exceed a limit ( starter box). Initially at position 1, as the speed increases, the starter move to position 2,3,4and 5, Development of a DC motor starter Example 13.1 A 10 kW , 100 V , 1000 rpm dc machine has Ra=0.1 ohm and is connected to a 100 V dc supply. a) Determine the starting current if no starting resistance is used in the armature circuit b) Determine the value of the starting resistance if the starting current is limited to twice the rated current c) This dc machine is to run as a motor, using starter box. Determine the values of resistance required in the starter box such that the armature current Ia is constraint within 100% to 200% of its rated value during start-up. Sol_pg21 Permanent Magnet DC motor • Widely used in low power application • Field winding is replaced by a permanent magnet (simple construction and less space) • No requirement on external excitation • Limitation imposed by the permanent magnet themselves such as demagnetization and overheating) Equation Ea = Kadm becomes Ea = Kmm Example 14 • A permanent magnet DC motor has Ra = 1.03 . When operated at no-load from a DC source of 50 V, its operates at 2100 rpm and draw a current of 1.25 A. Find: i. The torque constant, Km ii. The no-load rotational losses iii. The armature current and the motor power output when it is operating at 1700 rpm from a 48 V source Fgrt; pg 389: 0.22 V/(rad/sec), 61 W, 8.54A, 274 W Sol_pg23 Speed Control • Numerous applications require control of speed, as in rolling mills, cranes, hoists, elevators, machine tools, and locomotive drives. • DC motors are extensively used in many of these applications. • Control of dc motors speed below and above the base (rated) speed can easily be achieved. • The methods of control are simpler and less expensive than ac motors. • Classis way used Ward-Leonard System, latest used solid-state converters. Ward-Leonard System • In the classical method, a Ward-Leonard system(1890s) with rotating machines is used for speed control of dc motors. The system uses the motor-generator set ( M-G set) control the speed of a DC motor. Normally AC motor runs at constant speed is used as prime mover. The system is operated in two control methods: • Vt Control; In the armature voltage control mode, the motor current Ifm is kept constant at its rated value. The generator field current Ifg is changed such that Vt changes from zero to its rated. • If Control; The field current control mode is used to obtain speed above the base speed. In this mode, the armature voltage Vt remains constant and the motor field current Ifm is decreased to obtain higher speeds . Prime mover Ward-Leonard System Constant Constant Torque Region Power Region Solid-State Control • In recent years, solid state converters have been used (replace motor- generator set) to control the speed of dc motors. The converter used are controlled rectifiers or choppers: Controlled Rectifiers • If the supply is ac, controlled rectifiers can be used to convert a fixed ac supply voltage into variable-voltage dc supply (using SCR). High ripple, slow response Choppers • A solid state chopper converts a fixed-voltage dc supply into a variable-voltage dc supply(Using controllable swithes such as Power Mosfet, Power BJT, IGBT, GTO etc).Low ripple, fast response Controlled Rectifier 1-phase or 3-phase Single phase rectifier Vt Three phase rectifier Vt 2Vm cos 3Vml l cos Eg: Va and Vf Control using solid state devices – single phase supply If Ia Ta1 Ta3 + vs _ Ta4 Ra + Va La + Ta2 E g ARMATURE Lf + Tf3 Tf1 + vs _ Vf Lf Tf2 FIELD Tf4 Chopper Control Vt DVin Ton Vin T Closed-loop Operation • Open loop operation: If load torque changes, the speed will change too – not satisfactory. • May not be satisfactory in many applications where a constant speed is required • Close loop operation: the speed can be maintained constant by adjusting the motor terminal voltage as the load torque changes. (eg. Load torque increases, speed decreases, speed error eN increases, results in control signal Vc increases – decrease in the converter firing angle (controlled rectifeir), or increases in duty cycle (chopper) to restore back the speed) Speed demand Voltage control Chopper or Control rectifier Closed loop speed control system (basic system) Speed demand Current/torque demand Closed-loop speed control with inner current loop Example 15 • The speed of a 10 hp, 220 V, 1200 rpm separately excited DC motor is controlled by a single-phase full-controlled converter. The rated current is 40 A. Ra= 0.25 ohm, and La= 10mH. The AC supply voltage is 265 V. Motor constant is Ka=0.18 V/rpm. Assume the motor current is constant and ripple free. For firing angle = 30 degree, determine: (a) Speed of the motor (b) Motor Torque (c) Power to the motor. Sol_pg34 Sen pg 191 Example: 2009/10 Question 3 (a) Describe briefly classification of self-excited DC motor based on connections of field circuit and armature circuit. Sketch the torque speed profile for this type of motor. (b) A 500 V shunt motor takes a current of 21 A and runs at 400 rpm on full load. The armature resistance and field resistance are 0.3 and 500 respectively. In order to control the speed, an additional resistance is added in series in the armature circuit. The flux remains constant in the machine. (i) Sketch the new schematic diagram with armature resistance motor speed control. (ii) Find the motor speed at full load when an additional resistance of 2 is added in armature circuit. (iii) Find the motor speed at double full-load with added resistance of Qb(ii). (iv) Find the motor starting current with an additional resistance of 2 . (v) Find the required value of the additional armature resistance to reduce the speed to half of its rated speed at full load. Sol_pg32