Polytank Hazards

advertisement

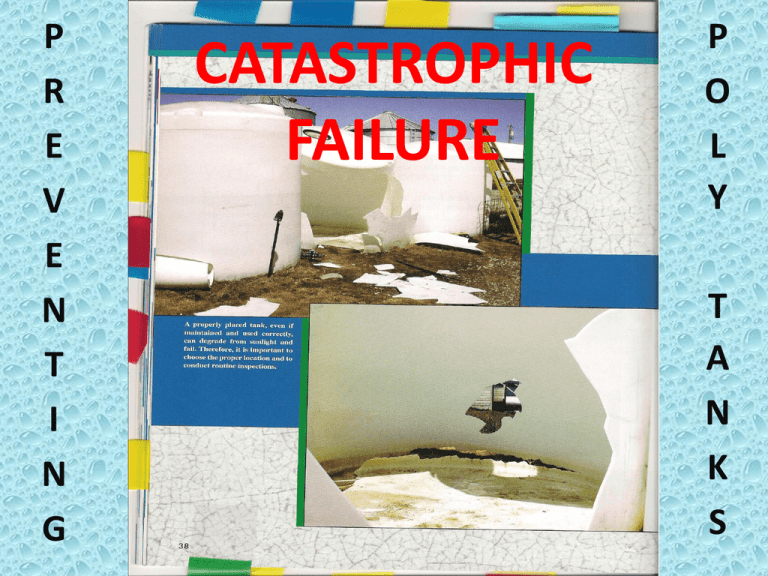

P R E V E N T I N G CATASTROPHIC FAILURE P O L Y T A N K S Preventing Poly Tank Failures • • • • Purpose of this presentation is : # 1 – Identify the problem # 2 – Demonstrate what to look for # 3 - Provide information to assist employers and protect employers and employees The Issue: Preventing CATASTROPHIC Failure of Poly Tanks • Poly tanks can fail: – 0-30 years – Many tanks are at the 12 year mark – There are increasing failures in storage • Failure is caused by: – Improper use – Sunlight breaking down the plastic The GOAL • Is to replace the tanks prior to FAILURE to prevent serious injuries, economic & environmental costs. Poly Tank 101 Two Types: #1 – Vertical Storage #2 - Transport Tank Design • Vertical tanks- also called stationary, upright, or hockey puck tanks • Horizontal tanks – side-to-side, transport, application or leg tanks • Significant design difference between the two dictate how they should or should not be used. • Using a tank outside it’s design specs voids the manufacturer’s warranty and increases odds of a failure. Follow the Manufacturer’s Requirements QUIZ: Improper Use What does a transport tank have that the storage tank does not? Do you see a problem here? Storage Tank Placement • Level • Tied down • In a location that, when it goes, will have minimal impact. Proper Placement? Proper Placement? Factors that Influence Longevity • • • • High specific gravity rating Infrequent refilling Protection from UV radiation Stationary placement Not all tanks are the same SPECIFIC GRAVITY • A tank’s specific gravity rating is a measurement of its ability to hold material. The specific gravity of a substance is a comparison of its weight per unit volume to that of water. • The weight of water is 8.334 pounds per gallon • Tanks are designed at 1.0 to 1.9 or more. Specific Gravity, cont. • A poly tank with a specific gravity of 1.0 is designed to hold the weight of water or any other liquid that weighs 8.334 pounds (or less) per gallon. • A poly tank rated at 1.5 is designed to handle the weight of a liquid product 1.5 times the weight of water (1.5 X 8.334); so a 1.5 s.g .tank is build to withstand the internal forces of liquids weighing up to 12.5 pounds per gallon. Specific Gravity • Important for grower to recognize the type needed for his/her particular storage needs. • Specific gravity is noted on the tank Horizontal “Transport “Tanks • Horizontal tanks are mounted to steel skids or fastened to trailers • If they have legs, each entire leg must rest on the trailer. • Those without legs must rest in a cradle that supports them from end-to-end and surrounds one-third of their circumference Horizontal “Transport” Tanks • Baffles – Poly tank manufacturers recommend that horizontal transportation tanks that hold more than 1.000 gallons be mounted lengthwise on the truck or trailer. – If mounted across the width of the truck or trailer the baffles would be out of position to control the content as it surges forward and backward during transit. Horizontal “Transport” Tanks • Metal Bands and Hoops – Sometimes required for structural strength and stabilization – Bands often are made from sheet metal, which has excellent tension strength, however the bolts that hold the metal to the trailer or cradle can become weakened. – Hoops are made of structural steel tubing or pipe and can withstand the powerful c\forces exerted by liquid contents when a transport vehicle stops quickly Horizontal “Transport” Tanks • Hoops & Bands must be tightened to remove all gap between bands/hoops and tank before filling and after filling but not causing tank distortion. • Improperly installed anchors can deform and weaken tanks • Metal bands can cut into the sides of the poly tank Poly Tank Attachments and Venting • The manner in which attachments are placed on poly tanks can decrease useful tank life • Rigid systems such as stainless steel or solid plastic pipe cause excessive stress in the valve and bung area. • Flexible connections are preferable. • Make sure all connections allow the tank to flex • Improper of nonfunctional vent can cause tanks to swell during loading or collapse. Inspections - Transport • Inspect tank before hauling for: • Missing, broken and bent bolts on the hoops or bands • Leaks around valves, tank bungs or lids or plumbing • Cracks or splits in hoses • Improperly secured hoses and covers • Vents in the lid or tank that are obstructed or clogged Inspections – Vertical Storage • Visual inspections should occur at each fill • Inspect for physical damage such as holes, dents, and abrasions • Make sure that the base remains solid • Check fittings for leaks Tank Inspections • Scratches are open to the surface; displaced material is evident on the tank’s surface; fingernail catches • Crazing is displayed as a patchwork of fine lines • Cracking causes no displaced material; very abrupt lines may run parallel or cross at right angles; UV cracking has a dry-rot or alligatorskin look in advanced stages; fingernail way catch Inspection Techniques • Writing with water-soluble ink • Candling with light • Louisville slugger • Now, for the visual demonstration…. Resources Dr. Fred Whitford, Purdue University 1-888-EXT-INFO http:www.ces.purdue.edu/new Publication # PPP-77