EARTHQUAKE PREDICTION USING CARBON

advertisement

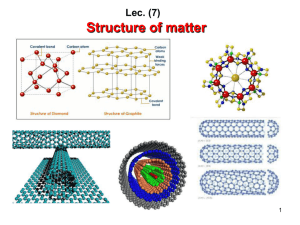

CARBON-NANOTUBES TECHNICAL SEMINAR PRESENTED BY : SHUHAB-U-TARIQ USN : 1SI03EC109 OUTLINE CARBON NANOTUBES Definition Structure Classification Properties Applications Drawbacks Conclusion Definition Carbon Nanotubes allotropes of carbon. extremely thin hollow cylinders made of carbon atoms. cylinderical fullerenes. Structure The name is derived from their size. The diameter of a nanotube is about 10000 to 50000 times smaller than the width of a human hair. Nanotubes are composed entirely of sp² bonds, similar to those of graphite. This bonding structure (stronger than sp³ bonds found in diamond) is responsible for their unique strength. Classification of Carbon Nanotubes Based on Conductivity metallic semiconducting Based on Chirality zig-zag armchair chiral Based on Layers single-walled multi-walled Classification based on Conductivity The conductance of a CNT is mainly affected by its chirality. Twisting is found to transform a metallic nanotube to a semiconducting one with a band-gap that varies with the twist angle. Metallic nanotubes can carry extremely large current densities. Semiconducting nanotubes can be electrically switched ON & OFF as FETs.The two types can also be joined covalently. Classification based on Chirality Described by chiral vector (n,m) where n & m are integers of vector =n, R = na1 + ma2 If R-vector lies along the armchair line, i.e. If Φ=0° … Armchair If Φ=30° If 0°<Φ<30° … Chiral … Zig-Zag Chirality Classification Contd. Chirality Classification Contd. n=m -- m=0 -- otherwise --- armchair zig-zag chiral Conductivity & Chirality If (n-m)/3 = 0 , tube is metallic If (n-m)/3 ≠ 0 , tube is semi-conducting Armchair (n=m) tubes are metallic Zig-Zag (m=0) & Chiral tubes are semi-conducting Classification based on Layers Single-walled CNTs SWNTs have one shell of C-atoms in a hexagonal arrangement. They can be thought of as a sheet of graphite rolled into a cylinder of about 1.2 to 1.4 nms in diameter. Layers Classification Contd. Multi-walled CNTs MWNTs consist of multiple concentrically nested C-tubes. Russian Doll model MWNTs Parchment model MWNTs PROPERTIES Size : 0.6 to 1.8 nm in diameter. Density : 1.33 to 1.40 grams/cm³. To make a comparison, Aluminium has a density of 2.7 grams/cm³. Tensile strength : 45 billion Pa. In comparison, high strength steel alloys break at about 2 billion pascals. High Elastic Modulus of about 1 TPa. Resilience : Can be bent at large angles easily (high ductility) and re-straightened without damage. PROPERTIES CONTD. Current carrying capacity : Estimated at a 1 billion amps/cm². i.e. more than 1000 times greater than metals such as silver & copper--(Cu-wires burn at about 1 million amps/cm²). Heat transmission : Predicted to be as high as 6,000 watts per meter per kelvin at room temperature. Compare this to copper (a metal well known for its thermal conductivity) which only transmits 385 W/m/K. Temperature stability : Stable up to 2,800 °C in vacuum, 750 °C in air. PROPERTIES CONTD. Defects In the form of atomic vacancies. Stone Wales Defect – creation of pentagonal and heptagonal pair by rearrangement of bonds. Tensile strength dependent on the weakest segment. Lowered conductivity through defective region of tube. Applications of Carbon-nanotubes The physical properties of C-nanotubes make them of potential use in nanotechnology engineering. Energy Storage (for fuel cells) Composite Materials Field Emitting Devices (flat panel displays) X-rays to go : CNTs could shrink machines Nanotube Chemical Sensors CNTs used for Cheaper Desalination Applications Contd. Transistors Basic building blocks of ICs. CNT – acts as a channel between source & drain in a CNT-FET. Gain of CNT-transistor is 10-100 times more than Si-transistors used for present day ICs. Applications Contd. Disadvantage of these conventional CNT-FETs. Electric current significantly fluctuates with time. Current-voltage characteristic exhibits a hysterisis. Diagram of a conventional CNT-FET ( IBM Nanoscience Department ) Successful development of a CNT-FET with an operational stability more than 1000 times than that of conventional CNT-FETs. Surface of CNT covered with Silicon-nitride film Applications Contd. Stability of new CNT-FET almost 1000 times more. Applications Contd. Removal of time & voltage instability leading to a successful development of CNT-FETs. Drawbacks of Carbon-nanotubes Cost – approx.$1,500 per gram. High-quality nanotubes produced in very limited quantities – commercial nanotube soot costs 10 times as much as gold. Polydispersity in nanotube type. Can’t be produced selectively. Lack of synthesis & purification methods. Separation of CNTs after synthesis. No control over CNT length & chirality. Conclusion “The Next Big Thing Is Really Small” The remarkable properties of CNTs appear destined to open up a host of new practical applications & help improve our understanding of basic physics at nanometer-scale. CNTs – envisioned to be the most viable candidates to dominate the 21st century revolution in nanotechnology. References Physics of Carbon-nanotubes (by M. S.Dresselhaus and R.Saito, M.I.T) Nanotubes for Electronics (by Philip G.Collins and Phaedon Avouris) Carbon Nanotube Applications in Microelectronics (by G.S.Dusberg) Carbon Nanotubes for Electronic Applications (by W.I.Milne, Cambridge University) Carbon Nanotubes (by Anthony Kendall and Elizabeth Pfaff) Phisical Properties of Carbon Nanotubes (by Thomas A. Adams) http://www.nanotech-now.com http://www.azonano.com www.research.ibm.com/nanoscience/nanotubes.html http://en.wikipedia.org/wiki/Carbon_nanotube www.knowledgefoundation.com/nanotubes2000.html www.nature.com/nature/journal/v439/n7074/abs/439281a.html www.amazon.com/Carbon-Nanotubes-Synthesis-Properties-Applications/dp/3540410864 www.chm.bris.ac.uk/webprojects2001/andrews/nanotubes-uses.html