File

advertisement

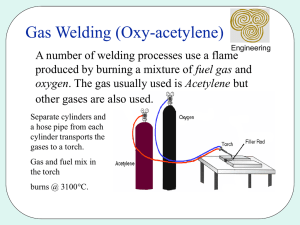

Question 1. State two precautions associted with oxyacetylene welding. • Oxygen should never be used instead of compressed air. • Special care must always be taken when using pressurised and flammable gases. • You must always wear protective clothing. • Goggles must be worn to protect your eyes from harmful rays. • All equipment must be checked regularly Question 2. Explain the two stage combustion process in Oxyacetylene welding. • Stages of combustion • Primary Combustion – Acetylene & Oxygen burn in the primary combustion zone to give off Carbon Monoxide and Hydrogen. • C2H2+O2 2CO+H2 • Secondary Combustion – oxygen is sucked in from the weld pool and is burned with Carbon Monoxide & Hydrogen to give off Carbon Dioxide and Water vapour. • CO+H2+O2 CO2+H2O Question 3. Explain the difference between a carburising and oxidising flame. The Oxidising Flame This is a result of excess Oxygen. Approx 1.5 parts oxygen to 1 part acetylene. If used with steel the excess oxygen would contimnate the joint, so it is used for copper and some bronzes. It has a temp. of about 3500ºC max temp zone inner cone secondary combustion zone Question 3. Cont. The Carburising Flame This is as result of excess Acetylene. Approx 0.9 parts oxygen to 1 part acetylene. Has a temp of approx 3150ºC and is used for welding alloy steels and aluminium alloys max temp zone inner cone secondary combustion zone C Acetylene Feather Question 4. State two functions of a flux in Oxyacetylene welding. • It protects the weld pool from oxygen and nitrogen. • It prevents blowholes from forming in the weld. Question 5. State two functions of the electrode coating in manual metal arc welding • It facilitates the striking of the arc and enables it to burn steadily. • It picks up impurities and brings them to the surface to form slag. The slag reduces the cooling rate. • It provides a gas shield to keep oxygen and nitrogen away from the weld pool. • It increases the rate of melting. • It enables the use of AC for welding. • It gives good penetration. • It can increase or decrease fluidity for special functions. Question 6. State two factors to be considered when preparing a joint for welding • Ensure that the joint is clean and free from grease. • Edges may also be bevelled to allow good penetration and fusion. Question 7. Describe with the aid of a diagram, a manual metal arc welding circuit operating from a 220V ac power supply. Explain how such a circuit operates when supplying dc for welding Transformer Rectifier D1 Smoothing Capacitor D4 AC D3 AC High Voltage AC Low D4 DC DC at Low Voltage Question 7. Cont. • The function of the transformer is to step down the voltage without changing it’s frequency. It is done by two coils of wire a primary and secondary. The current is induced from one to the other, causing the voltage drop. This in turn causes the current to increase. • • • • • Converting ac to dc uses the rectifier. This is a Single-Phase bridge converter. It uses 4 Diodes. During one half-cycle of the Ac supply diodes D1 and D3 are conducting. During the next half-cycle D2 and D4 are conducting. Question 8. Describe with the aid of a diagram Metal Arc Gas Shielded welding. • Metal Inert Gas • Semi-automatic Process • Consumable Electrode fed automatically. • Argon gas protects the weld pool like a flux. • No slag produced. • Suitable for steel. Q9 Describe with the aid of a diagram Seam Welding Question 10. State three functions of a heat source in welding. • Must generate enough heat to melt the parent metals. • Must be able to melt the filler rod. • The heat source must be able to be controlled. Question 11. Explain the special precautions necessary foe welding in confined spaces. • Good ventilation if possible. • Breathing equipment in special cases. • No flammable materials in the area. Question 12. Why is it more difficult to weld aluminium that mild steel? It is more difficult to weld aluminium because on the application of heat there is a build up of a hard layer on the surface of the aluminium, which makes it difficult to weld. Q13. describe with the aid of a diagram Tungsten Arc Gas Shielded Filler Rod • Tungsten Inert Gas • Non –consumable Electrode. • Filler rod used. • Argon gas protects the weld pool like a flux. • Suitable for Aluminium & Stainless Steel. Q14 Describe with the aid of a diagram Electro-Slag Welding Question 15. State two important functions of the slag produced in manual metal arc welding. • It helps shape the weld. • It slows down the cooling rate. • It protects the weld from contamination as it cools. Question 16. State two precautions which should be taken into consideration to eliminate hazards associated with mains operated welding equipment. • • • • Properly earthed. Correct cables Cables in good condition. Correct fuse. Question 17. In manual metal arc welding explain, using suitable diagrams, the principles of operation when using: (i)ac (ii)dc. • AC Both types of MMA welding processes use step down transformers. These transformers use primary and secondary coils to change the voltage from 220240V to 80-100V which gives a much higher current for welding 220V • DC To supply DC for welding a rectifier is used. It consists of four diodes and a smoothing capacitor. A bridge Rectifier converts Ac to DC. 80V Rectifier D1 D4 AC in AC High Voltage AC Low Smoothing Capacitor D3 D4 DC out Question 18 Explain the function and advantage of each of the following: • Multi Runs. These are less brittle than single runs as successive layers will anneal the hard zones on the previous run. • Shielded Arc The weld pool must be protect at all times from the atmosphere, this can be done with an inert gas or the burning of flux. This can stop slag inclusion and other problems. • Edge Preparation. The pieces to be welded must be clean a free from grease. This will ensure that no foreign matter in the weld lowering quality. • Slag this helps to shape the weld and it also slows down cooling which reduces brittleness. Question 19. Explain the function of each part of a welding regulator. • Pressure gauge 1- This indicates the pressure of the contents of the bottle. • Pressure Gauge 2- This indicates the pressure of the gas leaving the bottle. • Valve- This opens and closes the bottle. Question 20. Describe the following defects and suggest a remedy in each case. • Slag Inclusion. Foreign matter entrapped in the weld caused by dirt or contamination from the atmosphere. Remedy-Weld on clean surfaces with correct filler rod and flux. • Porosity Gas entrapped in the weld due to excessive moisture. Remedy-Dry electrodes and dry work piece. • Lack of Penetration. Welding current set too low or incorrect diameter rod. Remedy- Check the above. Question 21. Describe the principles, functions and application of Spot Welding. Question 22. Describe the principle, function and application of Friction Welding. Friction Welding A B • When A & B come into contact the friction causes them to fuse together. • This is a result of A rotating a high speeds and B brought into contact with a large force. • This process is used for joining shafts. Q23 Describe Submerged arc Welding Question 24. What is meant by dissolved Acetylene? • Acetylene cannot be compressed as it would explode. It is absorbed in the cylinder by a substance called acetone. Acetone can absorb 25 times it’s own volume of acetylene, this is dissolved acetylene.