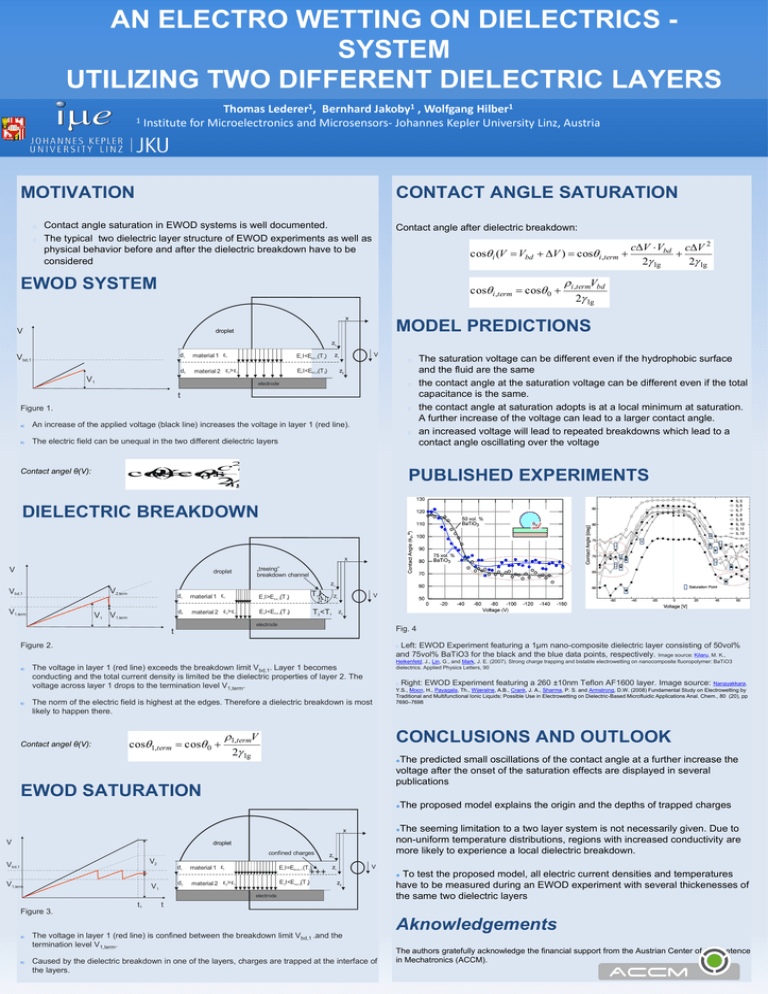

AN ELECTRO WETTING ON DIELECTRICS SYSTEM

UTILIZING TWO DIFFERENT DIELECTRIC LAYERS

Thomas Lederer1, Bernhard Jakoby1 , Wolfgang Hilber1

1 Institute for Microelectronics and Microsensors- Johannes Kepler University Linz, Austria

MOTIVATION

CONTACT ANGLE SATURATION

Contact angle saturation in EWOD systems is well documented.

The typical two dielectric layer structure of EWOD experiments as well as

physical behavior before and after the dielectric breakdown have to be

considered

Contact angle after dielectric breakdown:

cos i (V Vbd

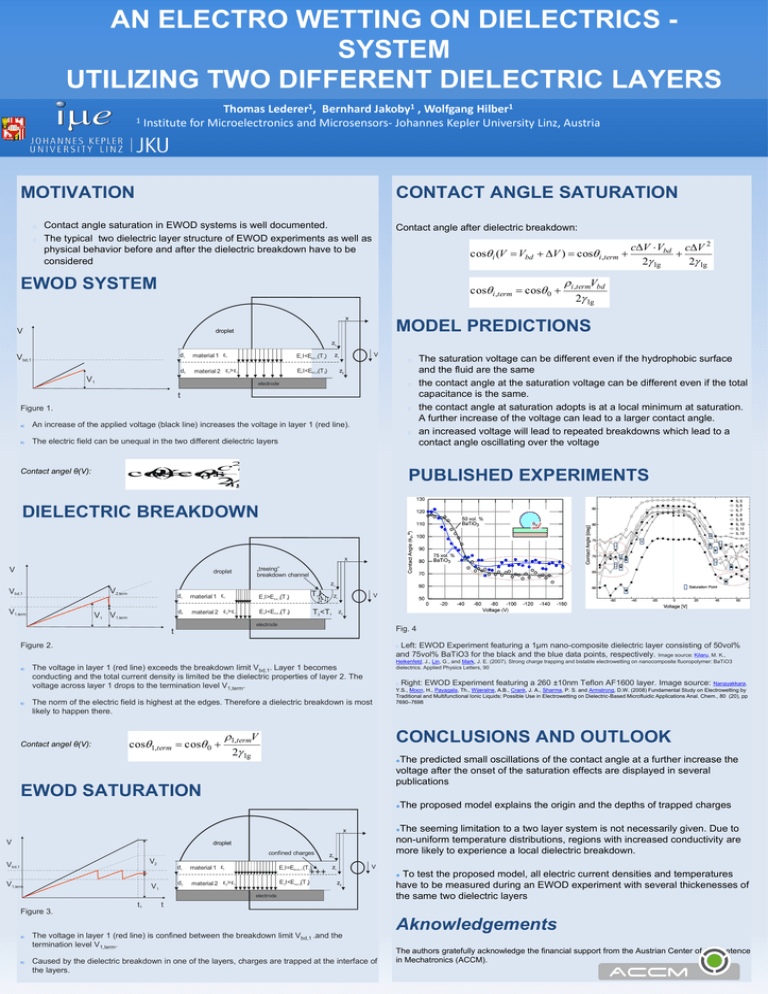

EWOD SYSTEM

cos i ,term

x

V

cV Vbd cV 2

V ) cos i ,term

2 lg

2 lg

i ,termVbd

cos 0

2 lg

MODEL PREDICTIONS

droplet

z1

Vbd,1

d1

material 1 ε1

E1I>Eb d ,1(T 1) E1 I<Eb d ,1(T 1)

d2

material 2 ε2> ε1

E2I<Eb d ,2(T 2) E2 I<Eb d ,2(T 2)

V1

V

zi

The saturation voltage can be different even if the hydrophobic surface

and the fluid are the same

the contact angle at the saturation voltage can be different even if the total

capacitance is the same.

the contact angle at saturation adopts is at a local minimum at saturation.

A further increase of the voltage can lead to a larger contact angle.

an increased voltage will lead to repeated breakdowns which lead to a

contact angle oscillating over the voltage

z2

electrode

t

Figure 1.

a)

An increase of the applied voltage (black line) increases the voltage in layer 1 (red line).

b)

The electric field can be unequal in the two different dielectric layers

Contact angel θ(V):

2

cV

cos

V

cos

0

2

lg

PUBLISHED EXPERIMENTS

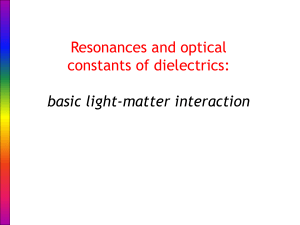

DIELECTRIC BREAKDOWN

x

V

droplet

„treeing”

breakdown channel

z1

V2,term

Vbd,1

V1,term

V1 V1,term

d1

material 1 ε1

E1I>Eb d ,1(T 1)

T1

d2

material 2 ε2> ε1

E2I<Eb d ,2(T 2)

T2 <T1

V

zi

z2

electrode

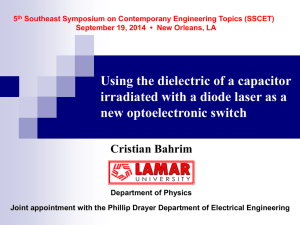

Fig. 4

t

Left: EWOD Experiment featuring a 1µm nano-composite dielectric layer consisting of 50vol%

and 75vol% BaTiO3 for the black and the blue data points, respectively. Image source: Kilaru, M. K.,

Figure 2.

a)

b)

Heikenfeld, J., Lin, G., and Mark, J. E. (2007). Strong charge trapping and bistable electrowetting on nanocomposite fluoropolymer: BaTiO3

dielectrics. Applied Physics Letters, 90

The voltage in layer 1 (red line) exceeds the breakdown limit Vbd,1. Layer 1 becomes

conducting and the total current density is limited be the dielectric properties of layer 2. The

voltage across layer 1 drops to the termination level V1,term.

Right: EWOD Experiment featuring a 260 ±10nm Teflon AF1600 layer. Image source: Nanayakkara,

The norm of the electric field is highest at the edges. Therefore a dielectric breakdown is most

likely to happen there.

Contact angel θ(V):

cos1,term

1,termV

cos 0

2 lg

Y.S., Moon, H., Payagala, Th., Wijeratne, A.B., Crank, J. A., Sharma, P. S. and Armstrong, D.W. (2008) Fundamental Study on Electrowetting by

Traditional and Multifunctional Ionic Liquids: Possible Use in Electrowetting on Dielectric-Based Microfluidic Applications Anal. Chem., 80 (20), pp

7690–7698

CONCLUSIONS AND OUTLOOK

The predicted small oscillations of the contact angle at a further increase the

voltage after the onset of the saturation effects are displayed in several

publications

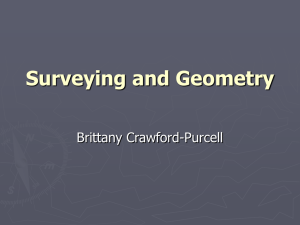

EWOD SATURATION

The seeming limitation to a two layer system is not necessarily given. Due to

non-uniform temperature distributions, regions with increased conductivity are

more likely to experience a local dielectric breakdown.

x

V

droplet

confined charges

V2

Vbd,1

V1,term

d1

d2

V1

material 1 ε1

material 2 ε2> ε1

E1 I=E

E1I>Eb d ,1(T

) te rm,1 (T1)

1

+++

E2I<E

(T 2)

E2I<Eb d ,2(T

b d ,2

2)

z1

V

zi

Figure 3.

a)

b)

To test the proposed model, all electric current densities and temperatures

have to be measured during an EWOD experiment with several thickenesses of

the same two dielectric layers

z2

electrode

t1

The proposed model explains the origin and the depths of trapped charges

t

The voltage in layer 1 (red line) is confined between the breakdown limit Vbd,1 .and the

termination level V1,term.

Caused by the dielectric breakdown in one of the layers, charges are trapped at the interface of

the layers.

Aknowledgements

The authors gratefully acknowledge the financial support from the Austrian Center of Competence

in Mechatronics (ACCM).