Lecture # 10 - Aamir Razaq

advertisement

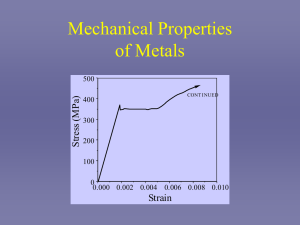

Elastic Compliance and Stiffness constant • Stress and strain: What are they and why are they used instead of load and deformation? • Elastic behavior: When loads are small, how much deformation occurs? What materials deform least? • Plastic behavior: At what point do dislocations cause permanent deformation? What materials are most resistant to permanent deformation? • Toughness and ductility: What are they and how do we measure them? • Ceramic Materials: What special provisions/tests are made for ceramic materials? 2 Normal & Shear components of stress Normal stress is perpendicular to the cross section, (sigma). Shear stress is parallel to the cross section, (tau). y y 3D case xy yx yz zx z Second subscript indicates the positive direction of the shear stress xy zy z First subscript indicates the axis that is perpendicular to the face xz x x Due to equilibrium condition; xy = yx zx = xz zy = yz Normal & Shear components of stress Two Dimensional Case y yx xy x x xy yx y Normal Stress Due to Axial Load A positive sign is used to indicate a tensile stress (tension), a negative sign to indicate a compressive stress (compression) Normal Stress Due to Bending Load Stress distribution Maximum stress at the surface M change in position Where I is area moment of inertia Shear Stress Due to Torque (twisting) Torsional stress is caused by twisting a member Stress distribution Maximum shear stress at the surface Where J is polar area moment of inertia Torsional Stress- examples Structural member Power transmission Mixer Combined Stresses - examples Bicycle pedal arm and lug wrench, bending and torsion stresses Trailer hitch, bending and axial stresses Billboards and traffic signs, bending, axial and torsion stresses Power transmission, bending and torsion stresses Understanding stress in terms of its components Stress is a Second Order Tensor It is easier to understand stress in terms of its components and the effect of the components in causing deformations to a unit body within the material These components can be treated as vectors Components of a stress: 2D 4 components [2 (tensile) and 2 (shear)] 3D 9 components [3 (tensile) and 6 (shear)] written with subscripts not equal implies (shear stress) e.g. xy xy First index refers to the plane and the second to the direction xx Plane Direction 2D xx yx xy yy xx xy yx yy 11 12 22 21 Let us consider a body in the presence of external agents (constraints and forces) bringing about stresses in the body. A unit region in the body (assumed having constant stresses) is analyzed. (body forces are ignored) Note: the directions of the stresses shown are arbitrary (the stresses in general could be compression/tension and shear could be opposite in sign) • Elastic Compliance and Stiffness Constants • The generalized Hooke’s law is an assumption, which is reasonably accurate for many material subjected to small strain, for a given temperature, time and location. • A mathematical expression of the stress-strain relation for the elastic deformation of materials was first suggested by Robert Hooke F is the applied force u is the deformation of the elastic body k is the material dependent spring constant Anisotropy and Isotropy • In a single crystal, the physical and mechanical properties often differ with orientation. • An anisotropic material is a material which does not behave the same way in all directions. Take wood for example. Wood is very strong along the grain. Against the grain, however, it will easily break. The opposite of an anisotropic material is an isotropic material. Most metals (steel, aluminum) are isotropic materials. They respond the same way in all directions. Figure 7-1 Anisotropic materials: (a) rolled material, (b) wood, (c) glass-fiber cloth in an epoxy matrix, and (d) a crystal with cubic unit cell. • Real materials are never perfectly isotropic. In some cases (e.g. composite materials) the differences in properties for different directions are so large that one can not assume isotropic behavior - Anisotropic. • There is need to discuss Hooke’s Law for anisotropic cases in general. This can then be reduced to isotropic cases - material property (e.g., elastic constant) is the same in all directions. • In the general 3-D case, there are six components of stress and a corresponding six components of strain. • In highly anisotropic materials, any one component of stress can cause strain in all six components. • For the generalized case, Hooke’s law may be expressed as: where, i Cij j i Sij j C Stiffness (or Elastic constant ) S Compliance • Both Sijkl and Cijkl are fourth-rank tensor quantities. • Expansion of either Eqs. will produce nine (9) equations, each with nine (9) terms, leading to 81 constants in all. • It is important to note that both ij and ij are symmetric tensors. • Symmetric tensor Means that the offdiagonal components are equal. For example, in case of stress: 13 31 , 12 21 23 32 We can therefore write: 11 12 13 11 12 13 21 22 23 12 22 23 31 32 33 13 23 33 Similarly, the strain tensor can be written as: 11 12 13 11 12 13 21 22 23 12 22 23 31 32 33 13 23 33 Elastic Deformation 1. Initial 2. Small load 3. Unload bonds stretch return to initial F Elastic means reversible. 22 Plastic Deformation (Metals) 1. Initial 2. Small load 3. Unload F Plastic means permanent. linear elastic linear elastic plastic 23 Typical stress-strain behavior for a metal showing elastic and plastic deformations, the proportional limit P and the yield strength σy, as determined using the 0.002 strain offset method (where there is noticeable plastic deformation). P is the gradual elastic to plastic transition. 24 Plastic Deformation (permanent) • From an atomic perspective, plastic deformation corresponds to the breaking of bonds with original atom neighbors and then reforming bonds with new neighbors. • After removal of the stress, the large number of atoms that have relocated, do not return to original position. • Yield strength is a measure of resistance to plastic deformation. 25 26 (c)2003 Brooks/Cole, a division of Thomson Learning, Inc. Thomson Learning ™ is a trademark used herein under license. • Localized deformation of a ductile material during a tensile test produces a necked region. • The image shows necked region in a fractured sample Permanent Deformation • Permanent deformation for metals is accomplished by means of a process called slip, which involves the motion of dislocations. • Most structures are designed to ensure that only elastic deformation results when stress is applied. • A structure that has plastically deformed, or experienced a permanent change in shape, may not be capable of functioning as 28 intended. Yield Strength, y tensile stress, y engineering strain, p = 0.002 29 Stress-Strain Diagram ultimate tensile strength 3 yield strength Strain Hardening UTS y necking Fracture 5 2 Elastic region slope =Young’s (elastic) modulus yield strength Plastic region ultimate tensile strength strain hardening fracture Plastic Region Elastic Region σ Eε σ E ε 1 E σy ε 2 ε1 4 Strain ( ) (DL/Lo) Stress-Strain Diagram (cont) • Elastic Region (Point 1 –2) - The material will return to its original shape after the material is unloaded( like a rubber band). - The stress is linearly proportional to the strain in this region. σ Eε σ or σ E ε : Stress(psi) E : Elastic modulus (Young’s Modulus) (psi) ε : Strain (in/in) - Point 2 : Yield Strength : a point where permanent deformation occurs. ( If it is passed, the material will no longer return to its original length.) Stress-Strain Diagram (cont) • Strain Hardening - If the material is loaded again from Point 4, the curve will follow back to Point 3 with the same Elastic Modulus (slope). - The material now has a higher yield strength of Point 4. - Raising the yield strength by permanently straining the material is called Strain Hardening. Stress-Strain Diagram (cont) • Tensile Strength (Point 3) - The largest value of stress on the diagram is called Tensile Strength(TS) or Ultimate Tensile Strength (UTS) - It is the maximum stress which the material can support without breaking. • Fracture (Point 5) - If the material is stretched beyond Point 3, the stress decreases as necking and non-uniform deformation occur. - Fracture will finally occur at Point 5. The stress-strain curve for an aluminum alloy. (c)2003 Brooks/Cole, a division of Thomson Learning, Inc. Thomson Learning™ is a trademark used herein under license. • Stress-strain behavior found for some steels with yield point phenomenon. 35 Toughness is the ability to absorb energy up to fracture (energy Toughness Lower toughness: ceramics Higher toughness: metals per unit volume of material). A “tough” material has strength and ductility. Approximated by the area under the stress-strain curve. 36 Toughness • Energy to break a unit volume of material • Approximate by the area under the stress-strain curve. Engineering tensile stress, smaller toughness (ceramics) larger toughness (metals, PMCs) smaller toughnessunreinforced polymers Engineering tensile strain, 21 Linear Elastic Properties • Hooke's Law: =E • Poisson's ratio: n x/y metals: n ~ 0.33 ceramics: n ~0.25 polymers: n ~0.40 Modulus of Elasticity, E: (Young's modulus) Units: E: [GPa] or [psi] n: dimensionless 38 Elastic Strain Energy • If the sample obeys Hooke's Law, and is below the elastic limit, the Elastic Strain Energy can be calculated by the formula: • E = ½Fx Example 2: Young’s Modulus - Aluminum Alloy From the data in Example 1, calculate the modulus of elasticity of the aluminum alloy. Assignment E 29 10 6 psi D 1.07 in. d 0.618 in. Determine the deformation of the steel rod shown under the given loads.