Hola Agustin - UniMAP Portal

advertisement

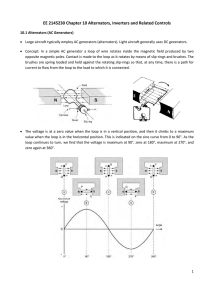

Lesson Objectives : Describe the construction and properties of alternating current generator Explain the operating characteristics of a.c generator 5.1 Introduction Alternating current is the primary source of electrical energy. It is less expensive to produce and transmit than direct current. These advantages, however, do not rule out the use of dc. DC generators are often used to provide power for operations such as metal refining, electroplating, and battery charging. DC generators have certain built-in limitations that restrict their power output. For this reason, and because ac voltage is induced into the armature of all generators, ac generators are generally more practical. 5.2 Types of alternator In dc generator the revolving part (rotor) is always the armature but in ac generator this is not usually true. There are 2 basic types of alternators: 1. The revolving armature type 2. The revolving field type The revolving armature type is similar in construction to the dc generator which is the armature rotates through a stationary magnetic field. But in dc generator, the generated ac in the armature windings in converted into dc by means of the commutator, whereas in the alternator, the generated ac is brought to the load as ac by means of slip rings, see fig 5.1. The revolving armature alternator is only found in alternator with small power ratings. It often used for very low power e.g. an automobile alternator, where both windings are interlaced on a stator and fields are coupled by a rotating soft iron (electromagnetic) armature without windings. Figure 5.1 Rotating armature alternator The revolving field type of alternator has a stationary armature winding and a rotating field winding. The advantage of having a stationary armature winding is that the generated voltage can be connected directly to the load without slip ring, see fig 5.2. Figure 5.2 Rotating field alternator Fixed connections are much more easily insulated than are slip rings at very high voltages, so high-voltage, high-power alternators are usually of the rotating field type. The voltage applied to the rotating field is low-voltage dc. The maximum current that an alternator can supply depends on the maximum heating loss that can be sustained in the armature. This heating loss (I2R power loss) heats the conductors, and if excessive, it can destroy the insulation. Alternator Alternators are rated in terms of this current as well as in terms of voltage output. Every alternator rating is expressed in volt-amperes or kilovolt-amperes of the apparent power that the alternator can supply. Even though the load may be drawing reactive (wattles) power, the I2R loss in the generator and feed line are real. 5.3 Alternator construction Alternators having high kilovolt-ampere ratings are usually of the turbine-driven, highspeed type. The prime mover for this type of alternator is a high-speed steam turbine driven by steam under high pressure. The steam is generated by nuclear power or the burning of oil, coal, or gas. The rotor of the turbine-driven alternator is cylindrical, small in diameter, and has winding firmly imbedded in slots in its face, see figure 5.3. Figure 5.3 Turbine-driven or cylindrical rotor The windings are arranged to form two or four distinct field poles. Only with this type of construction can the rotor withstand the terrific centrifugal force developed at high speeds without flying apart. In slow speed alternators, which are driven by variable-speed gasoline engines, water power, geared turbines, or electric motors, a salient pole rotor is used. In this type of rotor, a number of separately wound pole pieces are bolted to the frame of the rotor, see fig 5.4. Figure 5.4 Salient-pole rotor The field windings are either connected in series, or in series groups connected in parallel. In either case, the ends of windings usually connect to slip rings mounted on the rotor shaft. Regardless of the type of rotor field use, its winding are separately excited, usually by a dc generator called an exciter. In large ac generators, the exciter is connected to the same shaft as the main generator. However, in some very small ac generators, the rotor field is generated by a permanent magnet. The stator, or stationary armature of an alternator, holds the windings which are cut by the rotating magnetic field. The voltage generated in the stator as a result of this cutting action is applied to the load. The stators of all alternators are essentially the same. They consist of a laminated iron core, with the stator windings embedded in this core. The core is secured to the stator frame. 5.4 Number of poles / Frequency control The number of poles on ac generator depends upon the speed of rotation and the frequency we wish to produce. The frequency is given by the basic equation: F = PN/120 5-1 Where F = frequency of the induced voltage (Hz) P = number of poles on the rotor N = speed of the rotor (rpm) Example 5.1 A hydraulic turbine turning at 150 rev/min drives a synchronous generator rated at 400 MVA, 14 kV, 3 phase, 60 Hz. Calculate 1. How many poles does the rotor have? 2. What is the rated armature current per phase? Solution 5.5 Alternator characteristic Three factors affect the output voltage of an alternator. 1. The resistance of the stator windings. This resistance causes an IR drop within the generator. The value of the voltage drop increases with an increase in load 2. Self-induction takes place within the stator windings, causing an IXL drop. This voltage drop also varies with the load. 3. The power factor of the load also affects the output voltage.